Medical polymer splint processing device and processing method

A processing device and processing method technology, applied in the direction of chemical instruments and methods, lamination devices, layered products, etc., can solve the problems of large human errors in product length, unstable product quality, and difficulty in flattening at both ends, so as to improve work efficiency. Efficiency, flat end surface, and the effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

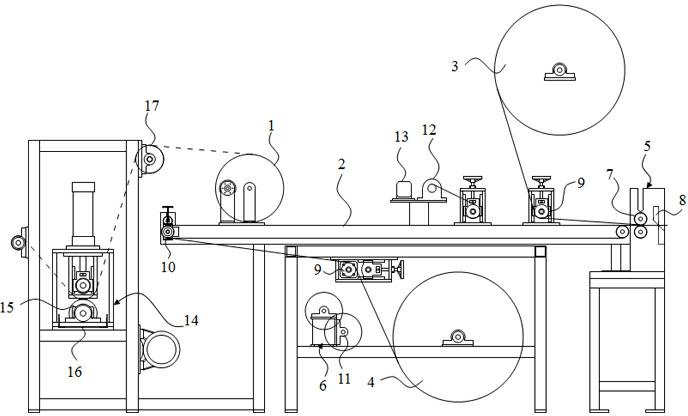

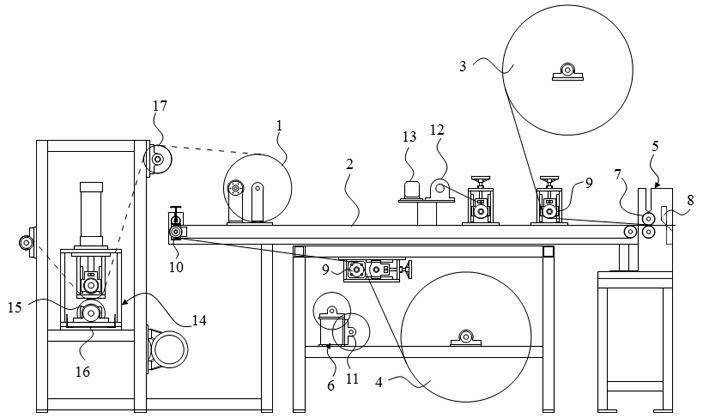

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

[0020] Such as figure 1 As shown, the base cloth is transmitted to the winding reel 1 through the gluing equipment 14 through the transmission roller 17. The gluing equipment 14 includes a rubber dipping roller 15 and a glue tank 16, and the rubber dipping roller 15 and the transmission roller 17 are driven at a constant speed by a reduction motor. , the dipping roller 15 coats the polymer resin in the glue tank 16 on the base cloth. The motor of belt conveyor 2 is a stepping motor, and the conveying end of belt conveyor 2 is provided with the cutter device 5 that is connected with stepper motor by PLC control, and cutter device 5 comprises the transfer roller 7 adjacent to belt conveyor 2 ends, and The gate cutter 8 controlled by the cutter motor. The upper and lower sides of the belt conveyor 2 are respectively provided with an upper roller 3 and a lower roller 4, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com