A visual on-line inspection device for appearance defects of cigarette sticks

A technology for appearance defects and detection devices, which is applied in the directions of optical testing defects/defects, packaging, packaging protection, etc., can solve the problems of slow processing speed and large volume of cigarette detection devices, avoid missed inspections, facilitate query management, reduce Effects of small complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The method of using the device of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

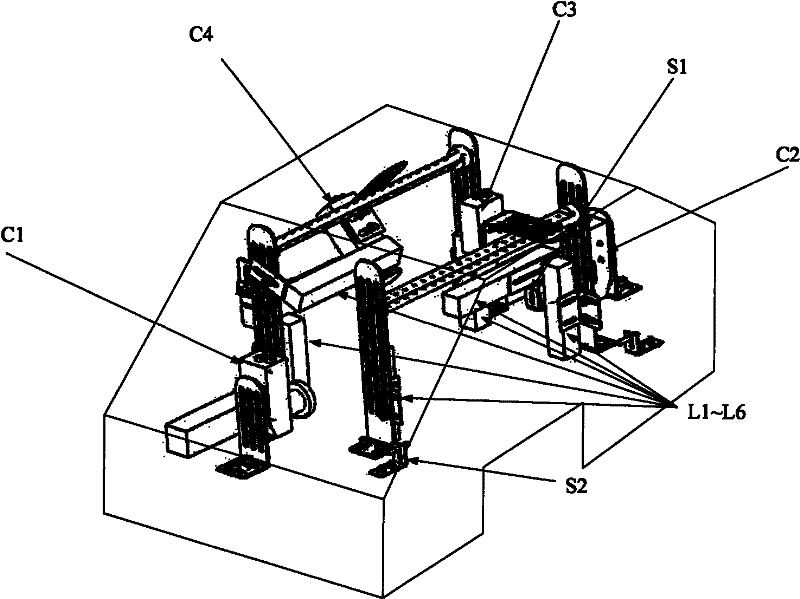

[0024] In order to reduce the labor intensity of inspectors, improve the quality of products leaving the factory, and reduce the labor cost and management cost of production enterprises, the present invention uses an intelligent camera combined with an image processing technology on-line inspection device to effectively detect wire-drawing errors that are common in strip packaging. Tooth, loss of transparent paper, damage to transparent paper, refolded carton paper, wrong brand of carton (mixed with other brands), severe folds of transparent paper, tearing of transparent paper and other packaging defects, and unqualified products will be removed from the production line out.

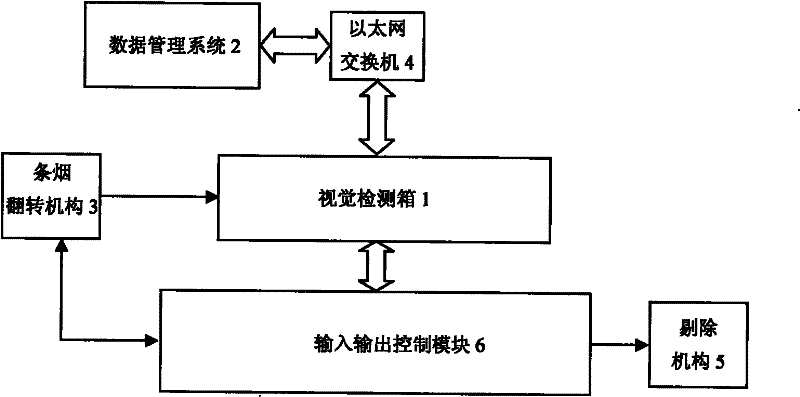

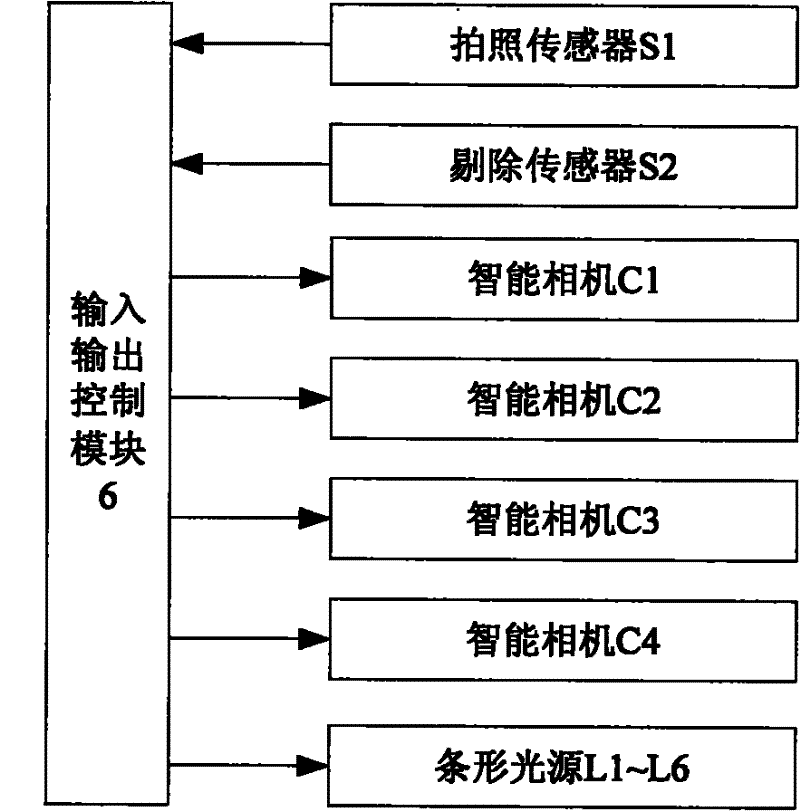

[0025] Such as figure 1 As shown, it is a schematic diagram of the electrical structure of the present invention, including a visual inspection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com