Intelligent carbonization furnace

A carbonization furnace and intelligent technology, applied in carbonization furnaces, coke ovens, special forms of dry distillation, etc., can solve the problems of uneven carbonization of materials, different color shades, affecting product quality, etc., and achieve uniform heating temperature, uniform color, and good quality. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention is described in detail below in conjunction with accompanying drawing and embodiment:

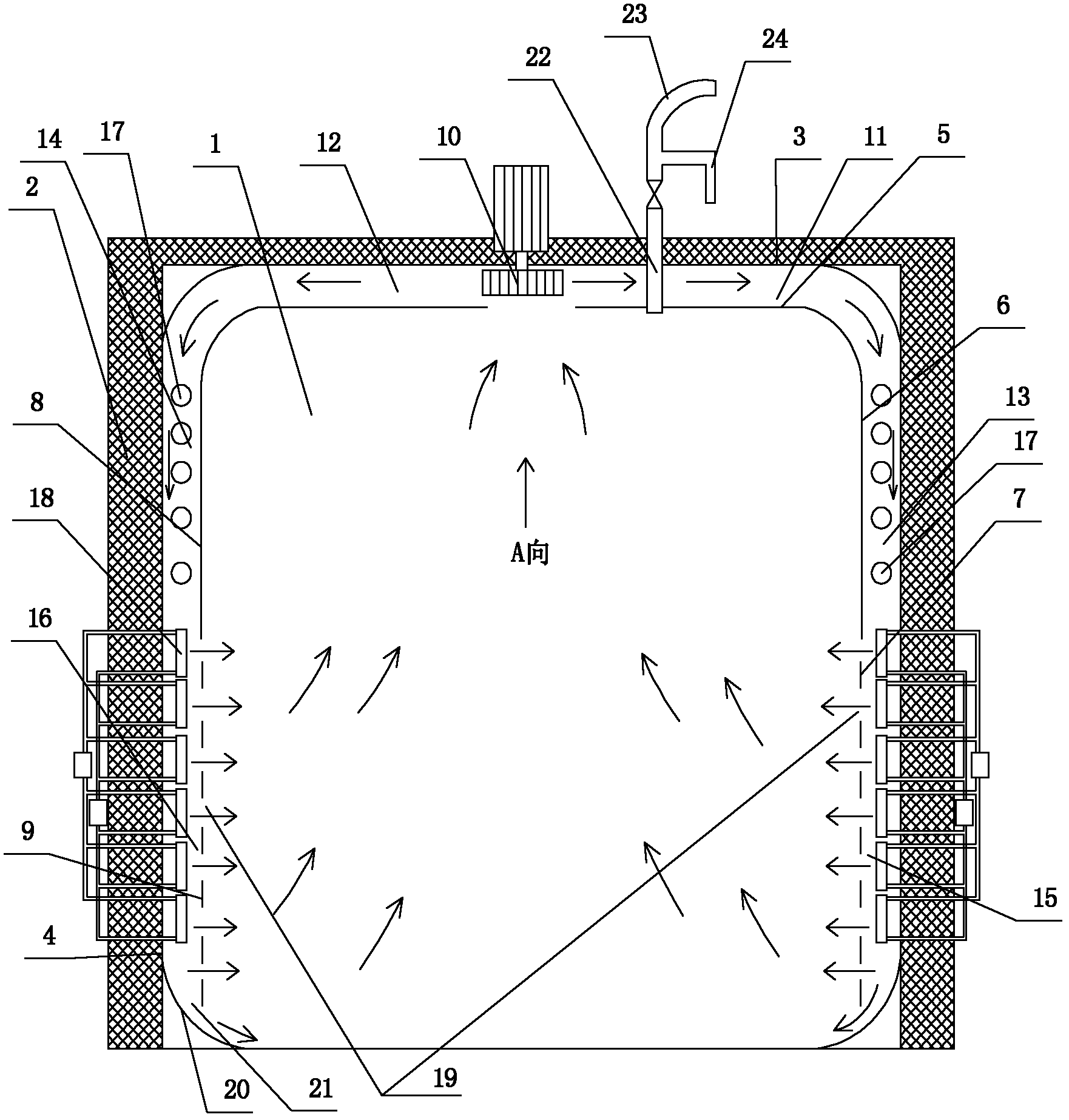

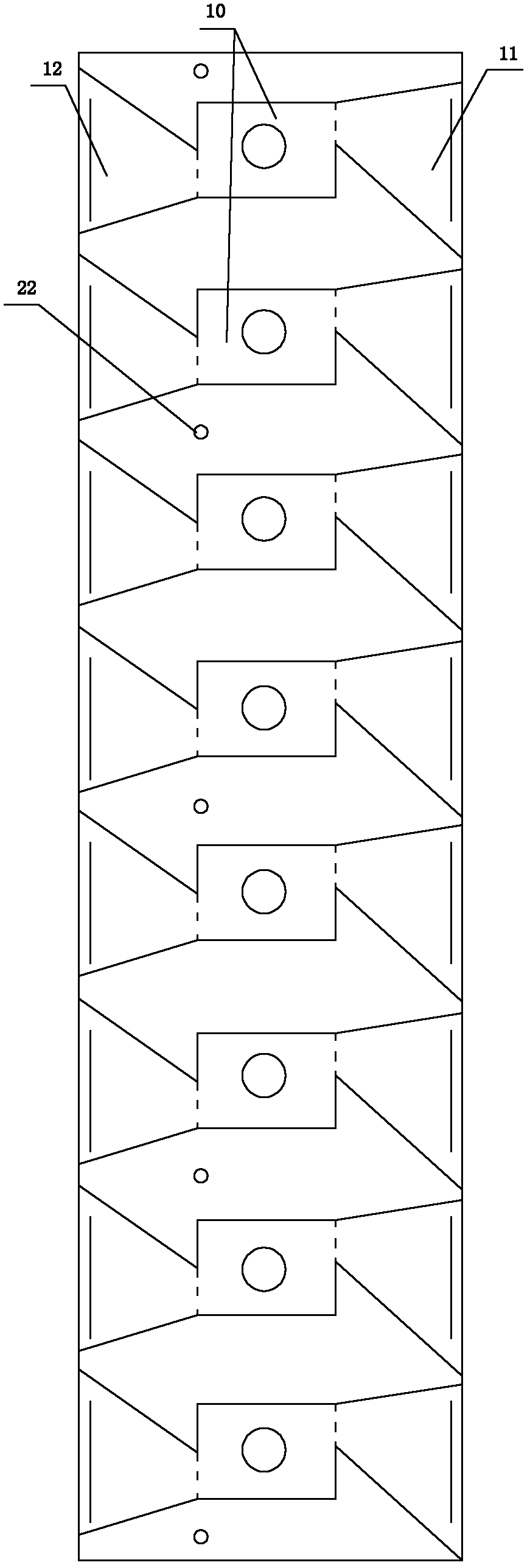

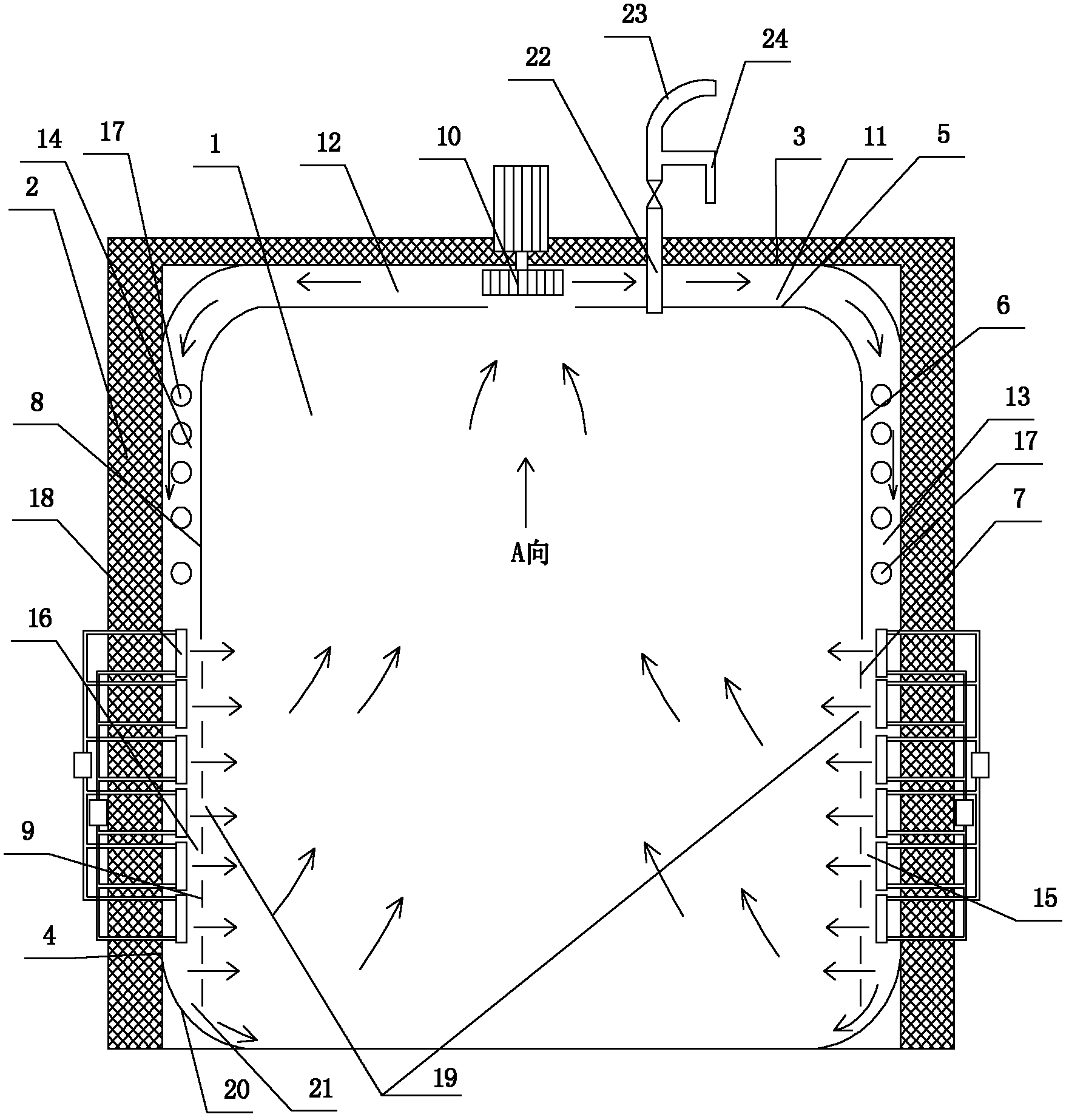

[0012] Such as figure 1 , figure 2 As shown, a kind of intelligent carbonization furnace of the present invention comprises a furnace body and a furnace body cavity 1, the furnace body includes a furnace body shell 2 and a furnace body wall, and the furnace body shell can be lined with refractory bricks, insulation layers, etc. Made, the inner wall of the furnace can be made of stainless steel plate or steel plate, the inner wall of the furnace is composed of the left top wall 3, the upper left wall, the lower left wall, the top right wall, the upper right wall and the lower right wall 4, and the furnace inner cavity 1 is mainly composed of The cavity surrounded by the rear wall, front wall, left top inner wall 5, left upper inner wall 6, left lower inner wall 7, right top inner wall, right upper inner wall 8 and right lower inner wall 9 has an opening on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com