Method for producing and synthetizing ammonia and methyl alcohol raw material gas by virtue of fixed bed intermittence type oxygenation nature gas

An intermittent technology for producing synthetic ammonia, applied in the manufacture of combustible gas, petroleum industry, etc., can solve the problems of small environmental pollution, large heat loss, strong coal selectivity, etc., and achieve the effect of reducing the difficulty of operation and easy adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] For further illustrating the present invention, specifically illustrate in conjunction with following examples:

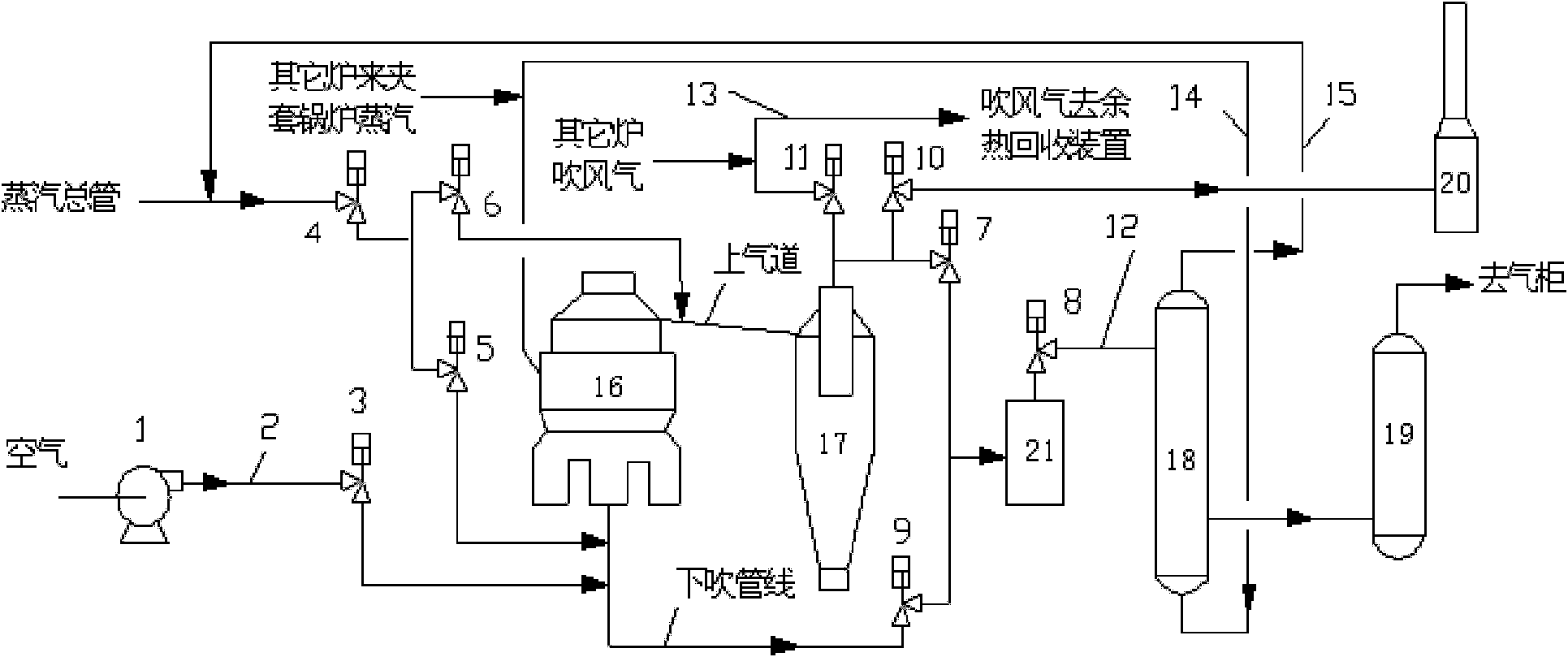

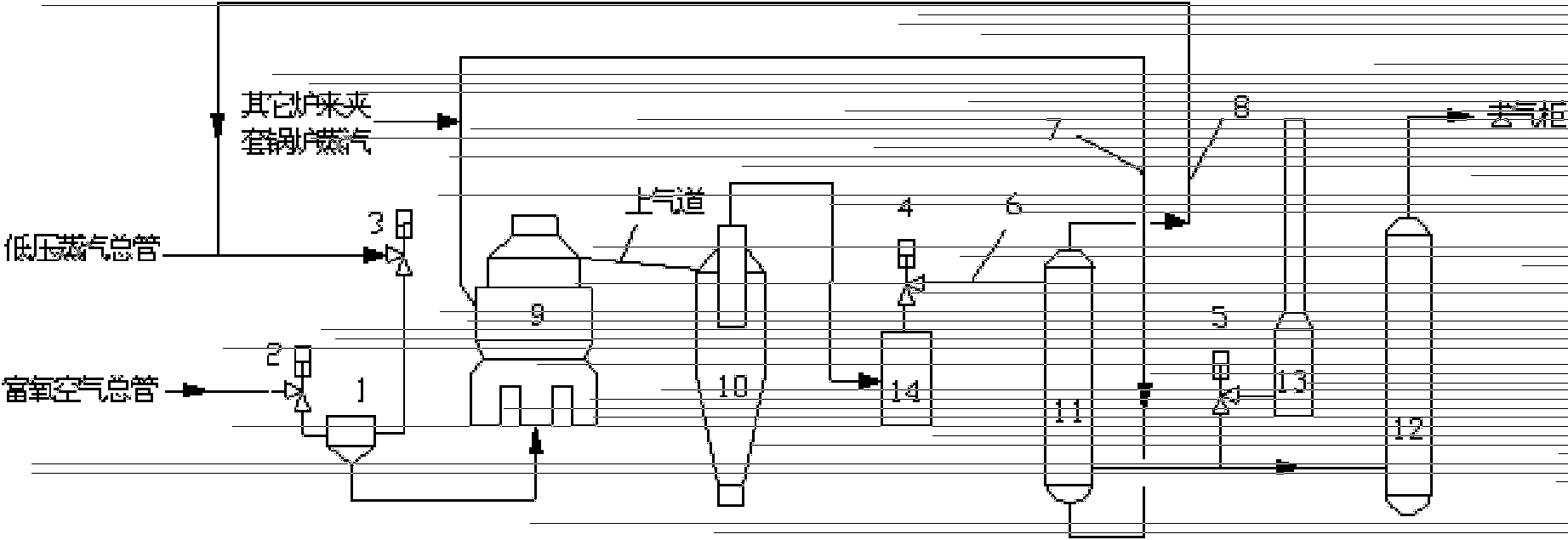

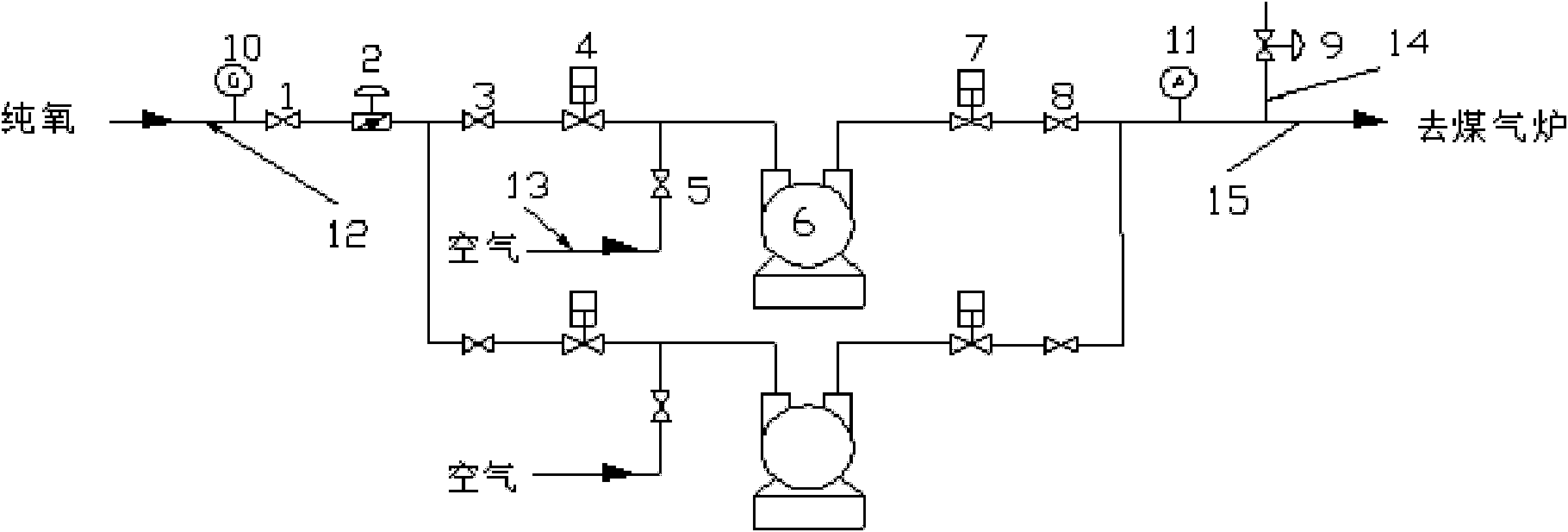

[0047] A fixed-bed intermittent oxygen-increased natural gasification method for producing synthetic ammonia and methanol raw material gas is based on the traditional fixed-bed intermittent gasification process, by increasing the oxygen concentration in the furnace air to improve the blowing efficiency and shorten the blowing stage time. When the concentration of oxygen reaches a certain level, the time of the blowing stage is zero. At this time, the two stages of blowing and air blowing in the fixed-bed intermittent gasification process are combined into the recovery stage of the intermittent oxygen-increased autothermal gasification process. Its technological process is as follows: (see Figure 4 ) A cycle of the fixed-bed intermittent oxygen-increased natural gasification process is divided into four stages: recovery, up-blowing, down-blowing, and second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com