Method for measuring deviation of nominal size of bore diameter of bearing inner ring

A bearing inner ring and measurement method technology, applied in the direction of mechanical diameter measurement, etc., can solve the problems of low work efficiency, heavy labor, and hollow steel pipes affecting the accuracy of measurement, etc., and achieve simple structure, reduced measurement error, and light weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

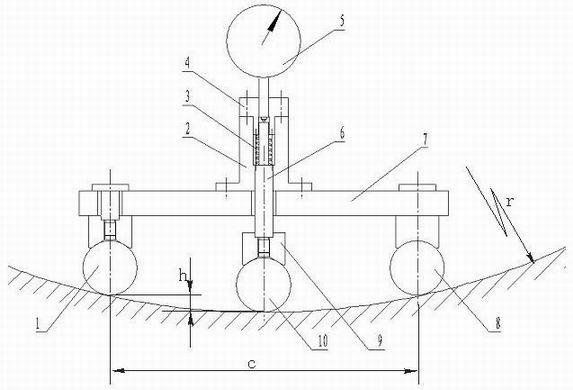

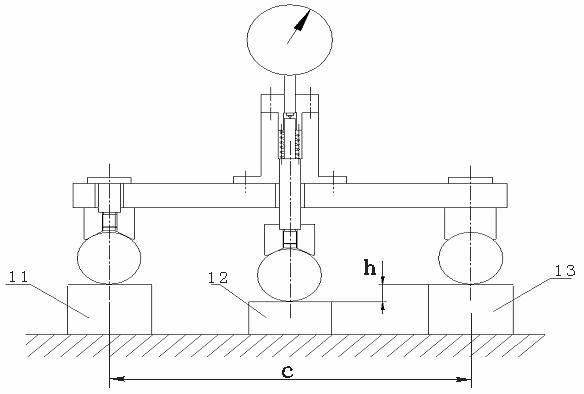

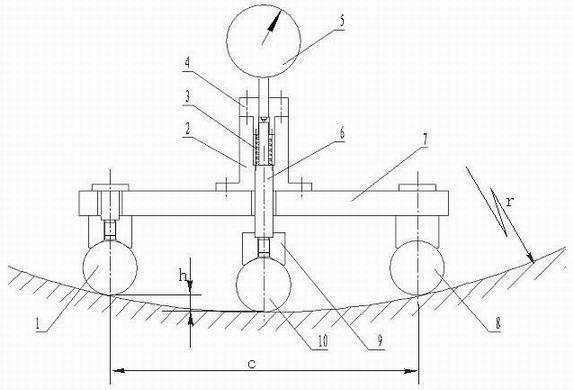

[0023] The invention relates to a method for measuring the deviation of the nominal size of the inner diameter of the inner ring of the bearing. The nominal size of the inner diameter of the inner ring of the bearing to be tested is set to 2r, and r is the radius of the inner ring of the bearing to be tested.

[0024] The measuring method of the present invention comprises measuring device, reference proofreading and measuring process three parts content, and these three parts content are described as follows:

[0025] combine figure 1 , the measuring device is designed according to the principle of "three points to determine a circular arc". The measuring device includes the first positioning ball 1, the positioning sleeve 2, the compression spring 3, the cover plate 4, the measuring instrument 5, the measuring rod 6, and the balance frame 7 , the second positioning ball 8, the limit sleeve 9 and the radially moving positioning ball 10, the symmetrical center of the gimbal 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com