A Synthetic Aperture Digital Holographic 3D Microscopic Observation Device with Smooth Reflective Surface

A technology of synthetic aperture and reflective surface, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problem that the hologram of the measured surface cannot be obtained effectively, and achieve the effect of compact structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below with reference to the drawings and embodiments.

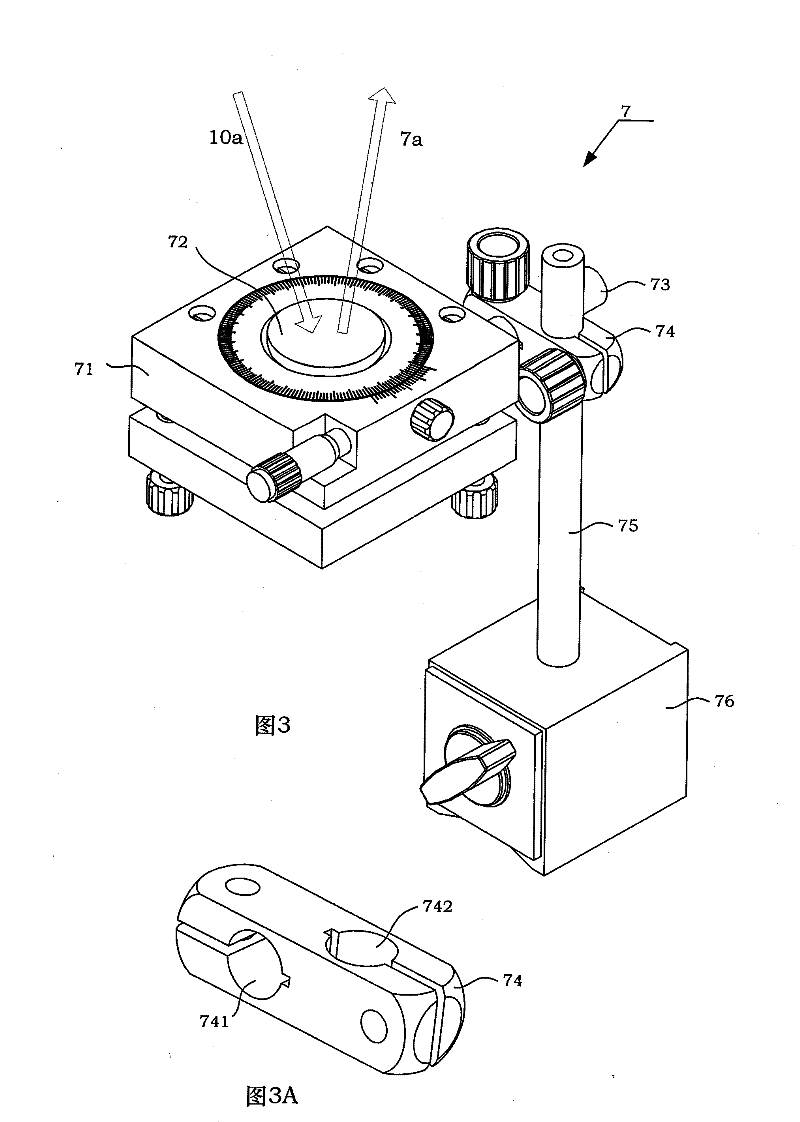

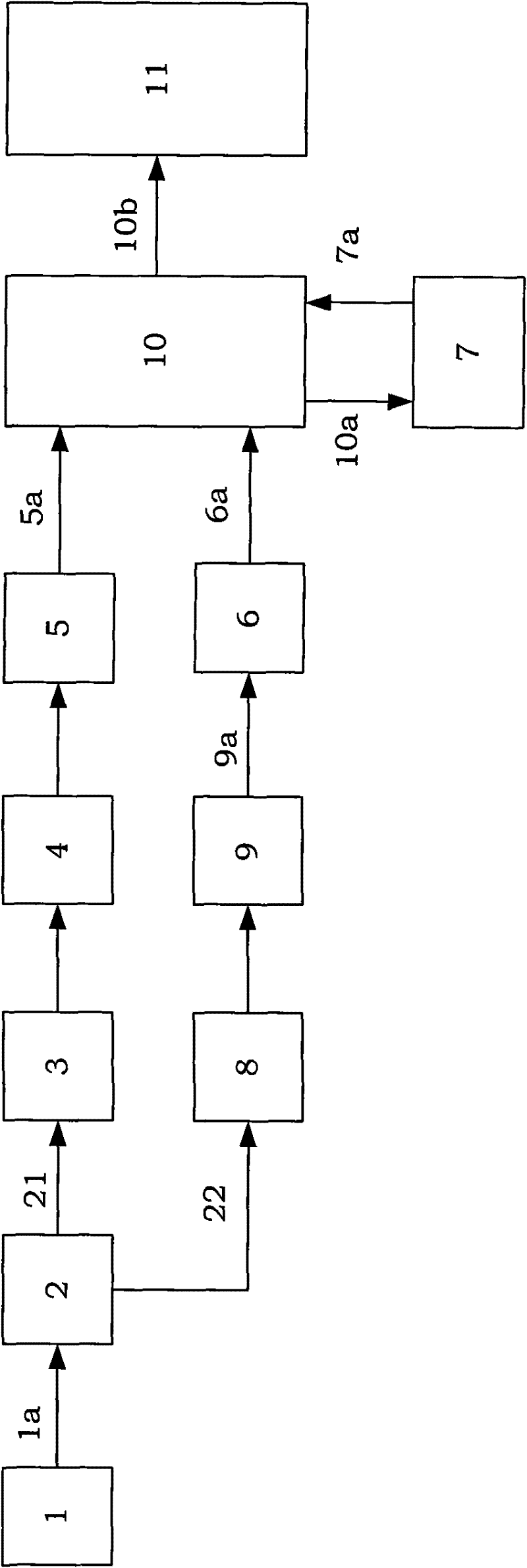

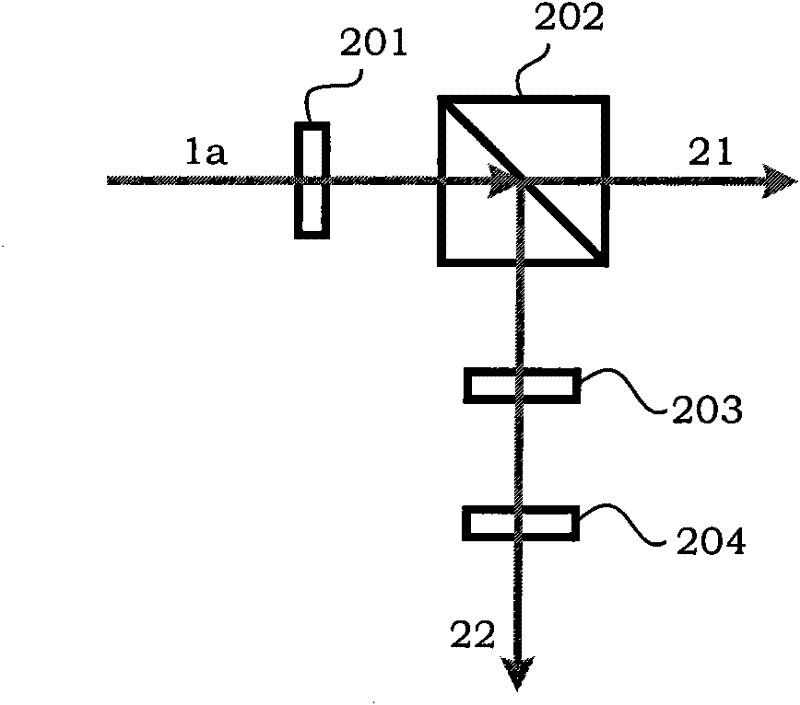

[0026] See figure 1 As shown, the present invention is a synthetic aperture digital holographic three-dimensional microscopic observation device for a smooth reflective surface. The device mainly includes a light source 1, a light splitting unit 2, a first spatial filter 3, a first plano-convex lens 4, and a third Plane mirror 5, depolarization beam splitter 10, CMOS camera 11, second spatial filter 8, second plano-convex lens 9, beam adjuster 6, rotating stage 7; among them, the first spatial filter 3 and the second The structure of the spatial filter 8 is the same; the structure of the first plano-convex lens 4 and the second plano-convex lens 9 are the same.

[0027] (1) Light source 1

[0028] In the present invention, the light source 1 is used to provide a 532nm laser 1a, that is, optical information. The light source provides a single longitudinal mode lase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com