Electric tire type gantry crane common DC bus device

A gantry crane and tire-type technology, applied in the direction of AC motor control, electrical components, single-network parallel feeding arrangement, etc., can solve the problems of energy waste and mutual utilization of energy, so as to reduce energy consumption and solve high energy consumption Problems, Effects of Realizing Recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

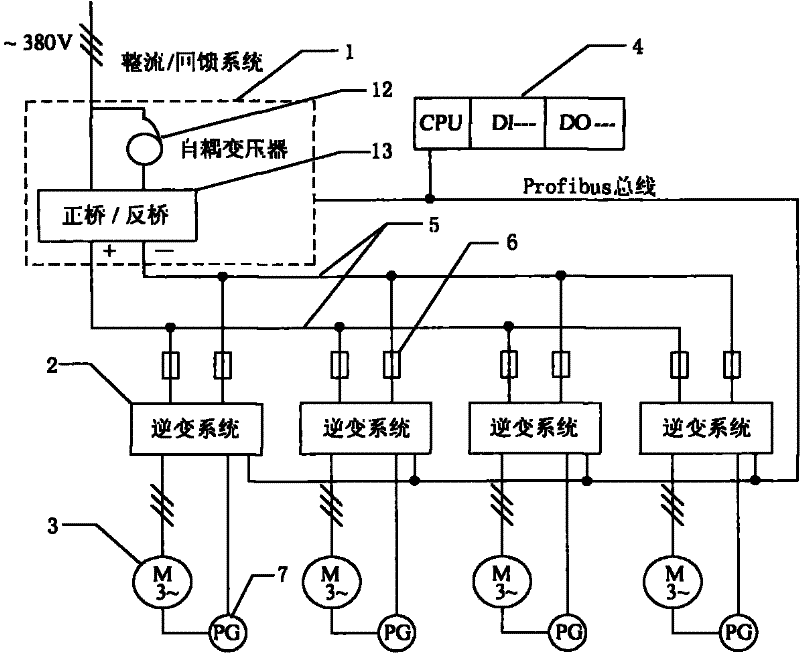

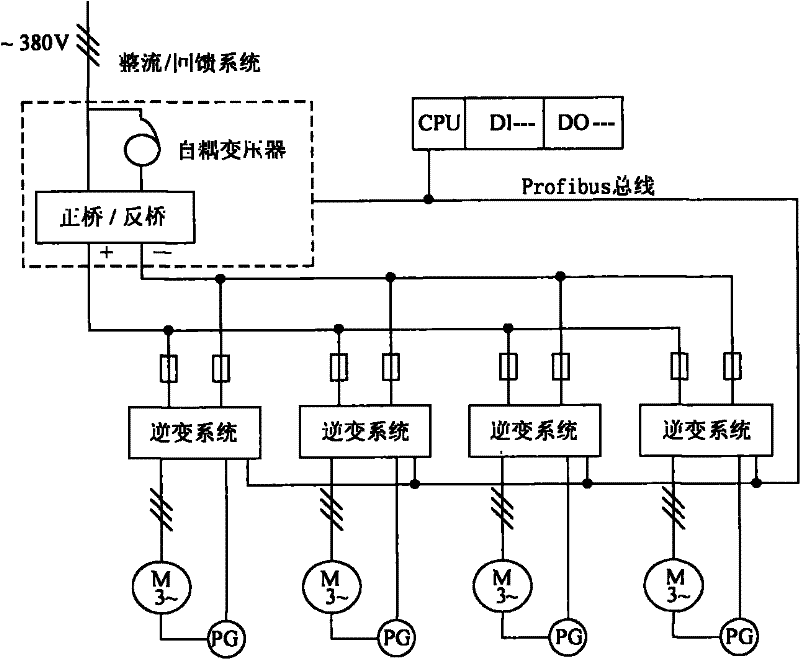

[0009] Such as figure 1 As shown, the motor (3) with the encoder (7) is connected to the inverter system (2) to realize the closed-loop control of the motor; the inverter system (2) is connected to the common On the busbar (5), the common busbar (5) is connected to the rectification / feedback system (1); the grid voltage is rectified through the positive bridge in the rectification / feedback unit (13), generating stable, Reliable DC voltage. The fed back electric energy is fed back to the power grid through the autotransformer (12) after inversion by the reverse bridge in the rectification / feedback unit (13), thereby realizing the feedback of electric energy. The PLC control system (4) is connected to the rectification / feedback system (1) and the inverter system (1) through the industrial field bus Profibus, which improves the stability and efficiency of the system.

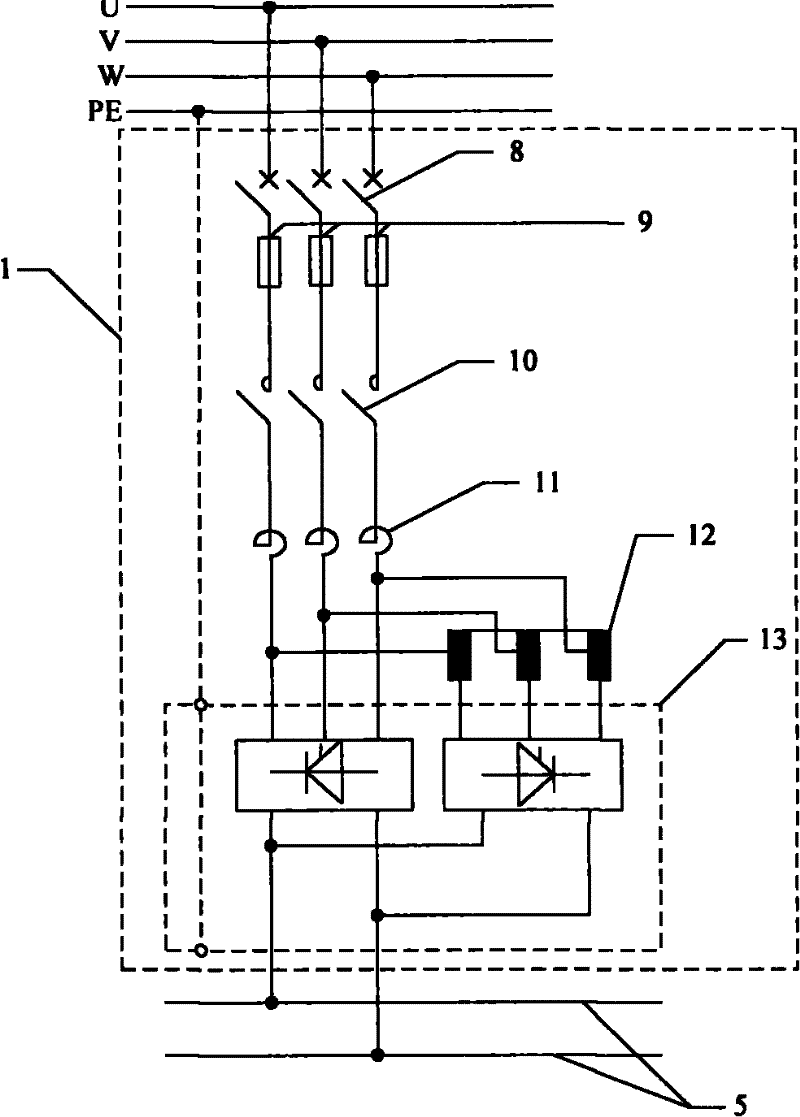

[0010] Such as figure 2 As shown, the rectification feedback / system (1) consists of five parts, the three-ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com