A kind of preparation method of copper-steel composite board

A composite board and copper board technology, applied in welding equipment, manufacturing tools, non-electric welding equipment, etc., can solve the problems of high cost and difficulty in achieving large single-pass deformation rate, and achieve wide thickness range, high quality, The effect of stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

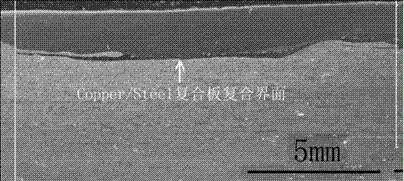

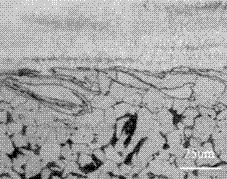

[0010] Example 1: The thickness of the copper plate is 2mm, the thickness of the steel plate is 5mm, the shaft shoulder of the stirring head is φ26mm, the stirring needle is a 2mm long M10 cylinder with right thread, the high-speed rotating stirring head is inserted into the copper plate, and the insertion amount is 2.1-2.4 mm, the rotational speed of the friction head is 750r / min, and the forward speed of the extrusion rod is 30mm / min. The angle of the stirring head is α=2°, for single-pass compounding, the width of the compounding area is 15.4mm, see figure 1 , figure 2 .

example 2

[0011] Example 2: The thickness of the copper plate is 3mm, the thickness of the steel plate is 10mm, the shaft shoulder of the stirring head is φ26mm, the stirring needle is a 3mm long M10 cylinder with right thread, the high-speed rotating stirring head is inserted into the copper plate, and the insertion amount is 3.2-3.5 mm, the rotational speed of the friction head is 750r / min, and the forward speed of the extrusion rod is 30mm / min. The angle of the stirring head is α=2°, and the compounding is carried out in three parallel paths, the distance between the paths is 9mm, and the width of the compounding zone is 30.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com