Differential bevel gear and rack compound underactuated robot finger device

A technology of robot fingers and bevel gears, applied in the field of humanoid robot hands, can solve the problems of difficult end pinching and grasping effects, lack of self-adaptability, large deformation of multiple spring parts, etc., and achieves convenient assembly and maintenance and simple structure , the effect of small energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The specific structure and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

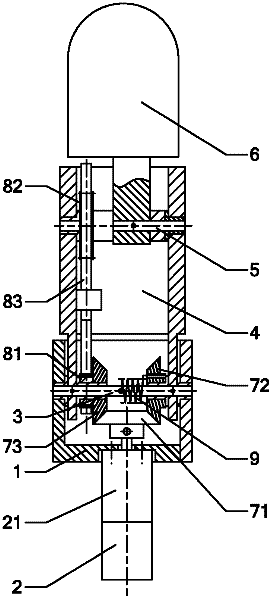

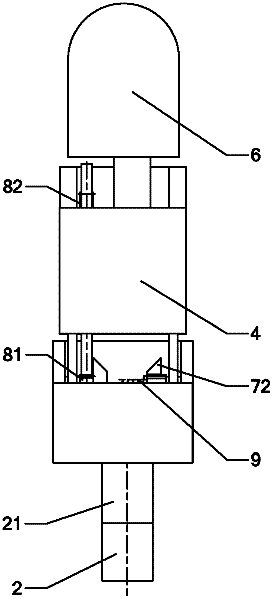

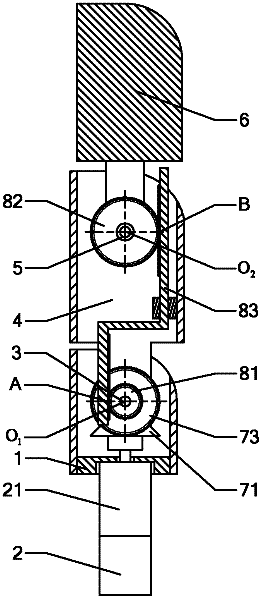

[0036] An example of the differential bevel rack and pinion compound underactuated robot finger device of the present invention, as Figure 1 to Figure 5As shown, it includes a base 1, a motor 2, a reducer 21, a proximal joint shaft 3, a middle finger segment 4, a distal joint shaft 5 and an end finger segment 6; the motor 2 and the reducer 21 are fixed on the base 1 Above, the output shaft of the motor 2 is connected with the input shaft of the reducer 21; the proximal joint shaft 3 is movably sleeved in the base 1, and the distal joint shaft 5 is movably sleeved in the middle finger segment 4, and the middle The finger segment 4 is fixed on the proximal joint axis 3; the terminal finger segment 6 is fixed on the distal joint axis 5, and the proximal joint axis 3 is parallel to the distal joint ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com