Method for increasing production of propylene and ethylene

A technology of ethylene and propylene, which is applied in the production of bulk chemicals, processing hydrocarbon oil, hydrocarbon cracking, etc., and can solve problems such as idle production capacity, quality degradation of cracking raw materials, and shortage of cracking raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] On the basis of Comparative Example 1, add a catalytic cracking system with catalytic cracking gasoline as raw material (see Table 3 for raw material composition), the processing capacity of cracked gasoline of this catalytic cracking system is 50,000 tons / year, and the specific flow chart is as in the manual As shown in the accompanying drawings.

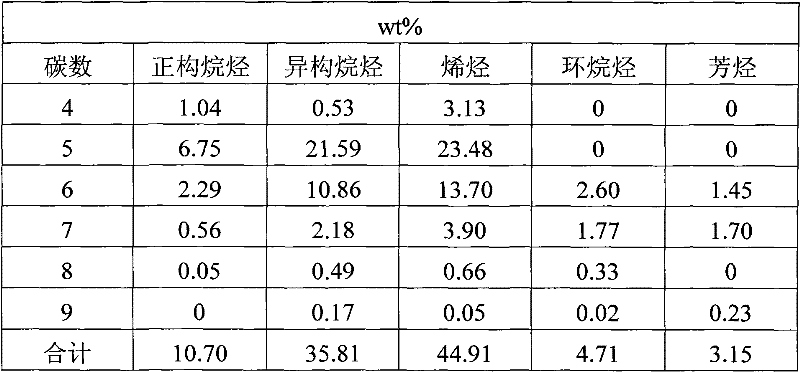

[0038] Table 3 Composition of FCC gasoline

[0039]

[0040] (1) First pass the catalytic cracking gasoline into the catalytic cracking reactor 1, the olefins of the catalytic cracking gasoline are contacted with a specific catalyst 1, and the olefin catalytic cracking catalyst is a small grain modified with phosphorus and / or alkaline earth metal (particle size is less than 800nm) ZSM-5 molecular sieve type catalyst, the composition of catalyst is: 5wt%P, 1wt%La, 64wt%ZSM-5 molecular sieve (silicon-aluminum ratio is 100, particle size is 500nm), 30wt% silicon oxide, Produced by Beijing Research Institute of Chemical Indu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com