Stabilization heat treatment process of wrought zn-al alloy

A stabilized heat treatment, Zn-Al technology, applied in the field of heat treatment of metal materials, can solve the problems of the deformation Zn-Al alloy stabilization heat treatment process, high process production cost, high efficiency, etc., to improve the dimensional stability of the alloy and comprehensive Mechanical properties, shortening the holding time, and the effect of shortening the time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

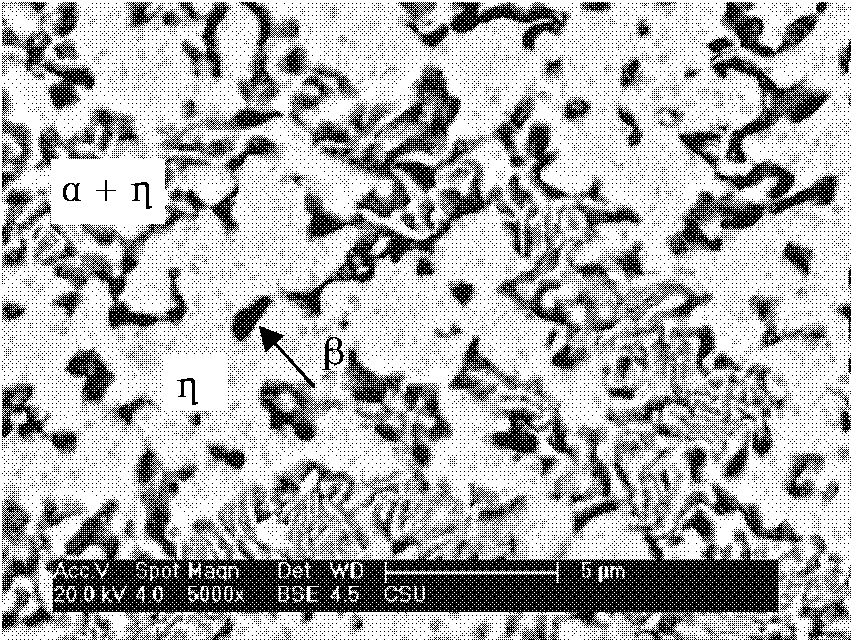

[0040] The composition is Al 10%; Cu 2.5%; Ti 0.5%; Mg 0.02%, Bi 0.03%; the rest is zinc and unavoidable impurities (impurity content ≤ 0.15%) deformed Zn-Al alloy extruded rod in the resistance furnace Stabilization heat treatment was carried out in the middle, heated to 360°C with the furnace, kept for 20 minutes, then cooled to 260°C with the furnace, kept for 10 minutes, cooled to 140°C with the furnace, kept for 8 hours, and cooled to room temperature in air. Microstructural analysis and mechanical performance test of the alloy after heat treatment, see attached figure 2 , Compared with the comparative example, in the deformed Zn-10Al alloy structure after the stabilization heat treatment of this embodiment, the non-equilibrium β (ZnAl) phase basically disappears, and the copper-rich ε phase basically disappears. See Table 1 for the mechanical property indexes of the alloy after the stabilization heat treatment in this embodiment.

Embodiment 2

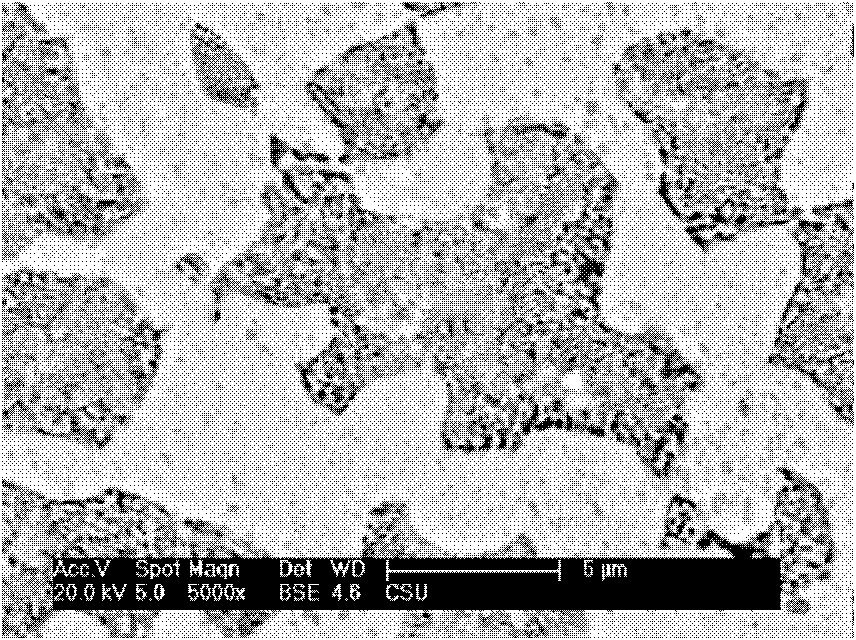

[0042] The composition is Al 10%; Cu 1.5%; Ti 0.5%; Mg 0.02%, Bi 0.03%; the rest is zinc and unavoidable impurities (impurity content ≤ 0.15%) deformed Zn-Al alloy extruded rod in the resistance furnace Stabilization heat treatment in the middle, heating to 340°C with the furnace, holding for 30min, then cooling to 225°C with the furnace, holding for 20min, then cooling to 90°C with the furnace, holding for 14h, air cooling to room temperature. Microstructural analysis and mechanical performance test of the alloy after heat treatment, see attached image 3 , compared with the comparative example, in the deformed Zn-10Al alloy structure after the stabilizing heat treatment in this embodiment, the non-equilibrium β (ZnAl) phase has undergone eutectoid reaction and transformed into α+η layer lamellar, cellular and granular structure, rich in Copper ε phase decreased. See Table 1 for the mechanical property indexes of the alloy after the stabilization heat treatment in this embod...

Embodiment 3

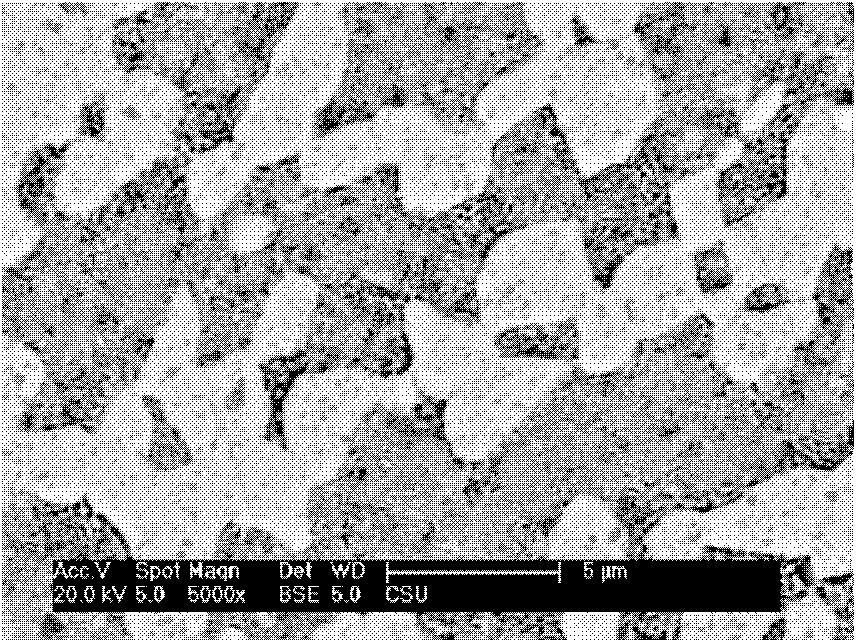

[0044] The composition is Al 10%; Cu 2.5%; Ti 0.5%; Mg 0.02%, Bi 0.03%; the rest is zinc and unavoidable impurities (impurity content ≤ 0.15%) deformed Zn-Al alloy extruded side in the resistance furnace Carry out stabilization heat treatment in the middle, heat up to 350°C with the furnace, hold for 25 minutes, then cool to 240°C with the furnace, hold for 15 minutes, then cool to 120°C with the furnace, hold for 10 hours, and air cool to room temperature. Microstructural analysis and mechanical performance test of the alloy after heat treatment, see attached Figure 4 , Compared with the structure of Example 1, the structure has not changed significantly. From the perspective of actual production, it is unnecessary to prolong the low-temperature annealing holding time. See Table 1 for the mechanical property indexes of the alloy after the stabilization heat treatment in this embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com