Controlling Oxygen by Filling Nitrogen to Prevent Gas Accidents in Coal Mine

A technology for coal mine gas and accidents, which is applied in the field of preventing and controlling coal mine gas accidents by filling nitrogen and controlling oxygen. It can solve the problems of frequent gas accidents and poor gas concentration control effect, so as to improve safety, save outburst prevention costs, and reduce outburst prevention indicators. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

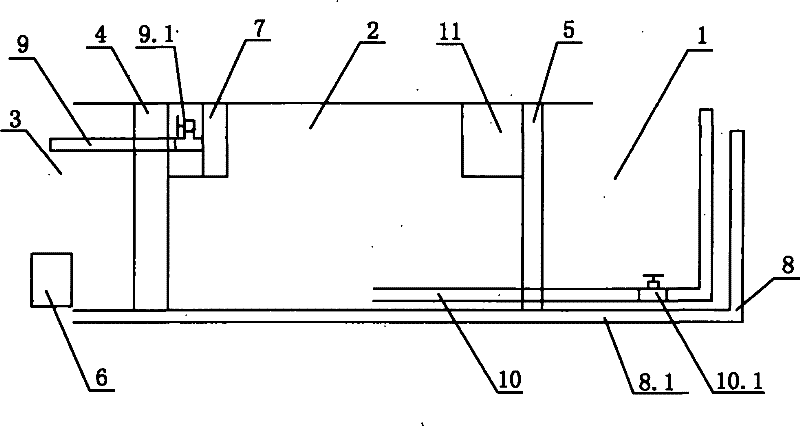

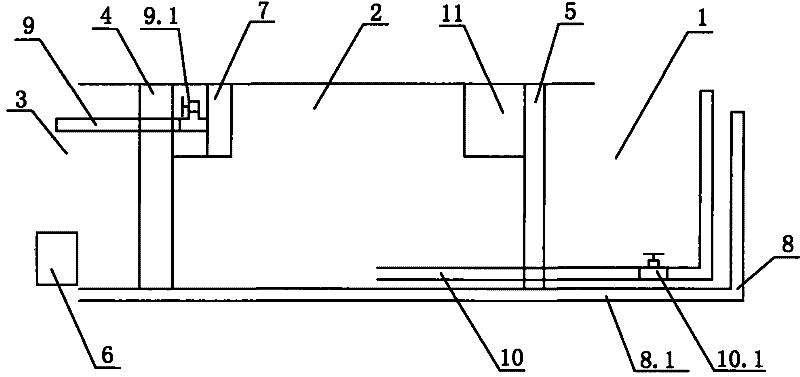

[0040] For the mine whose main shaft is arranged in hard and dense surrounding rock, it can be sealed between the shaft and the stone gate. The specific sealing method is as follows:

[0041] 1. Two isolation doors with good sealing performance shall be constructed before the 10-meter legal line distance before the first coal seam is opened in Shimen.

[0042] 2. There is a set of automatic temperature adjustment equipment 11 in the isolation room, which can compare and control the gas temperature between the two doors and the outside temperature. Before personnel and equipment (equipment) enter the door, start the temperature adjustment equipment to adjust the temperature, so The temperature between the two doors is more than 5 degrees lower than the outside temperature.

[0043] 3. Before personnel and equipment enter, open the nitrogen pressure inlet pipe in the door, press nitrogen in, and increase the gas pressure in the door. The temperature between the two doors is low...

example 2

[0045] 1. For the wellbore arranged along the inclined direction of the coal seam, the isolation room should be set at the initial section of the area where the surrounding rock is stable and the gas content of the coal seam has become high gas.

[0046] 2. Under normal circumstances, since the space position of the isolation room is lower than that of the outside air, it is only necessary to install a set of automatic temperature adjustment equipment 11, and adjust the temperature of the gas in the isolation room to be lower than the temperature of the outside air according to a temperature difference of more than 5 degrees, that is, It can effectively prevent the entry of outside air.

[0047] 3. In special cases, if the space position of the isolation room and the position of the mining space are higher than the position of the end face contacting the outside air, use the automatic temperature adjustment device to adjust the gas temperature in the isolation room higher than ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com