A vacuum loading device and its test method

A technology of loading equipment and vacuuming, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve problems such as the inability to meet the compression stability test of the upper wall plate of the central wing, and ensure reliability. and stability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below through specific embodiments:

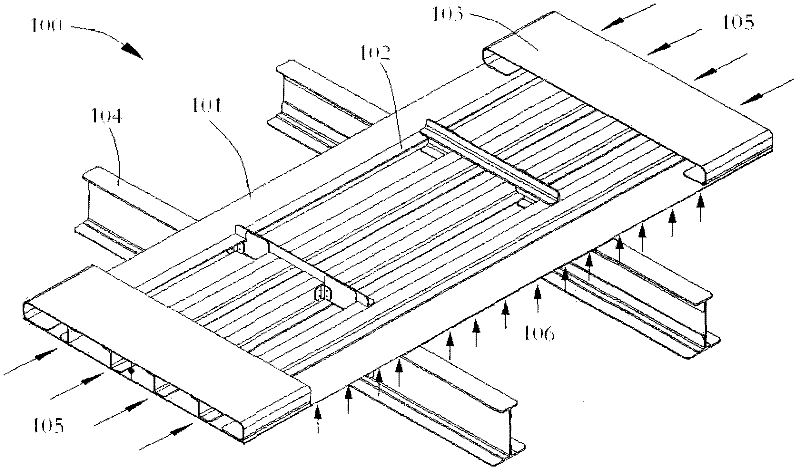

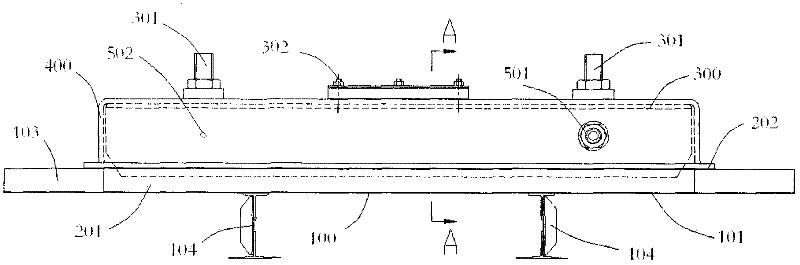

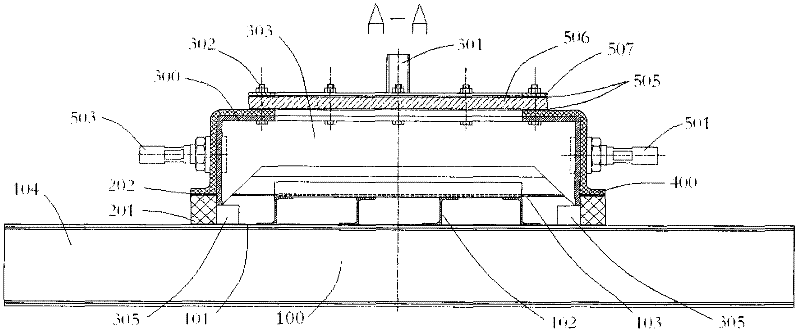

[0030] See also figure 2 , image 3 with Figure 4 ,among them, figure 2 It is a schematic structural diagram of a preferred embodiment of the vacuum loading equipment of the present invention, image 3 Yes figure 2 A-A section view, Figure 4 Yes figure 2 Top view. The vacuum loading equipment is mainly a vacuum box assembled on the upper wall of the center wing, which includes a rubber block 201, a sealing gasket 202, a support box 300, a sealing box 400, a cushion block 305, a rubber ring 505, a plexiglass plate 506, Steel pressing ring 507, sensor interface 501, outlet 502, air extraction interface 503 and air intake interface 504.

[0031] Among them, two rectangular rubber blocks 201 (40mm×47.5mm) are pasted on the edge of the skin 101 on one side of the wall truss, which are the key parts of the vacuum loading equipment. The rubber block 201 is flush with the bosses 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com