A joint detection method and device for detecting trace moisture and trace oxygen in industrial gases

A technology for industrial gas and trace water, which is used in measurement devices, electrochemical variables of materials, instruments, etc., can solve the problems of poor quality of electronic gas and high scrap rate of electrical products, and achieve the effect of prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

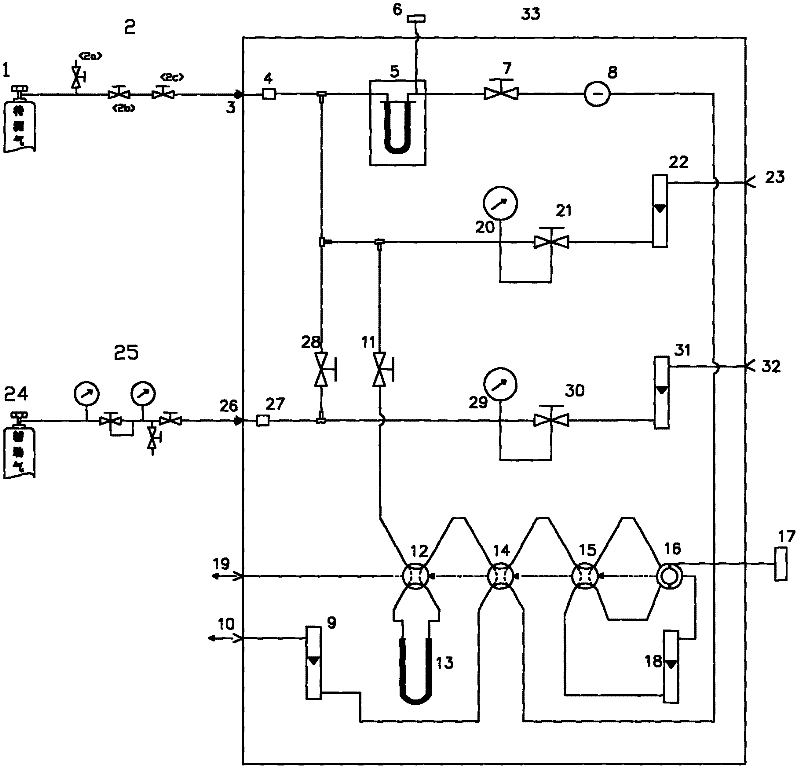

[0103] In conjunction with Fig. 1, the technical parameter setting in the joint detection method and device detection process of trace oxygen and trace moisture in the industrial gas of the present invention is illustrated:

[0104] The gas cylinder (1) to be tested passes through the sampling valve (2) and is connected to the sample gas inlet (3) of the chassis of the main engine (33).

[0105] The auxiliary gas (24) is connected to the auxiliary gas inlet (26) of the main engine (33) cabinet through the pressure reducer (25).

[0106] The auxiliary gas is generally of the same composition as the gas to be measured (or nitrogen and argon), but the purity is low and the price is low.

[0107] The flow rate of the gas to be tested is generally 500-800mL / min during the test, and it will be shut off immediately after the test is over; the flow rate of the auxiliary gas is 120mL / min, which is normally open during the gas cylinder use test, and can be turned off after the gas cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com