A kind of heavy oil storage stability test method and equipment

A technology of storage stability and test method, applied in the field of storage stability test of heavy oil and secondary processed oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

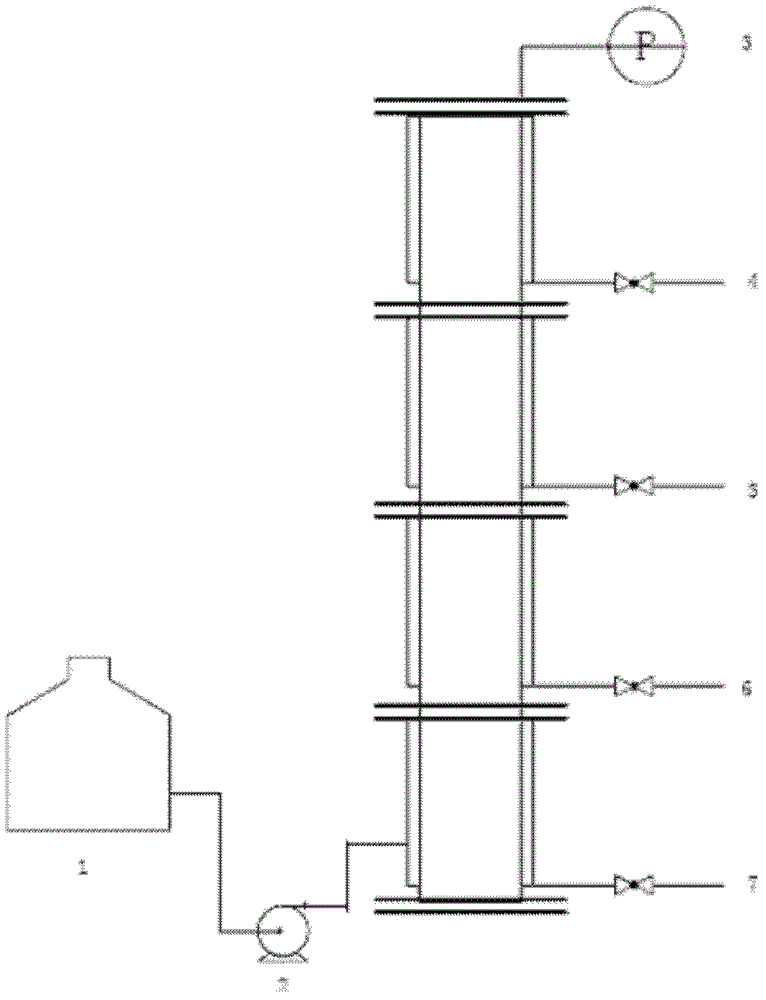

Image

Examples

Embodiment 1

[0013] In October 2009, the device was built in Gaofu Petrochemical Co., Ltd., a China National Petroleum Fuel Oil Company. The Venezuelan super-heavy oil visbreaking oil and the hydrogen-supplying thermal cracking reformed oil were loaded into different pipe strings, and the shipping temperature was 50-55 °C. Storage for 180 days, sampling every three days for analysis in the early stage, and sampling every six days after 30 days, to judge the stability of the upgraded oil based on the viscosity and spot test data, and complete Venezuelan super-heavy oil visbreaking and hydrogen supply thermal cracking upgrading The oil storage stability test for 180 days meets the requirements of long-term storage test and sampling analysis.

[0014] storage time, days Viscosity, mm 2 / s spot test, grade 0 125.2 II 30 118.2 II 60 118.4 II 90 119.9 II 120 122.6 II 150 124.2 II 180 125.0 II

Embodiment 2

[0016] In June 2010, the plant was built in PetroChina Liaohe Petrochemical Company, and the 90-day storage stability test of Venezuelan extra-heavy oil normal residue visbreaking and slag reduction hydrogen supply thermal cracking modified oil was completed in the same way, meeting the test requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com