Simulation test method for the effect of backflow of fuel cell stack gas components

A fuel cell stack and simulation test technology, applied in the fields of fuel cells, material separation, electrical components, etc., can solve the problems of lack of stack operation influence and optimal control, so as to shorten the development cycle, reduce energy consumption and equipment scale, The effect of reducing the reflux ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

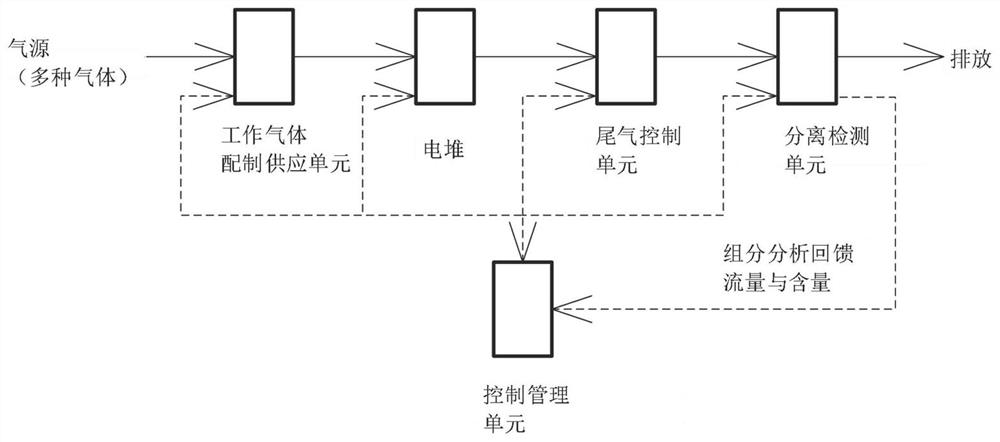

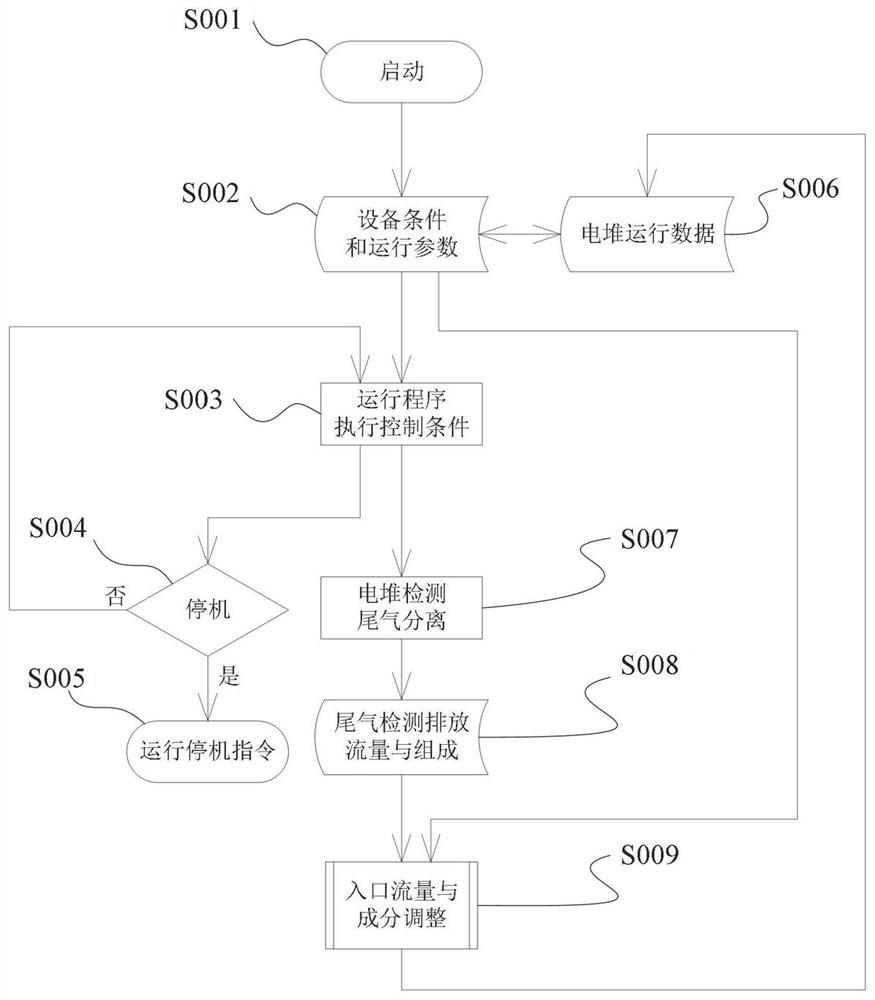

[0029] A simulation test method for the influence of backflow of fuel cell stack gas components: the stack is operated under the condition of allocated fuel and oxidant supply, and the stack flow is calculated according to the backflow ratio by analyzing the flow and composition of the stack exhaust gas And composition, the flow and composition feedback is used to readjust the gas composition and flow at the gas source, including water vapor, to obtain the same experimental conditions as simulated by the reflux method.

[0030] The simulation test system used for this simulation test method: includes a working gas preparation and supply unit, an exhaust gas control unit, and a separation detection unit connected in sequence through pipelines. Between the preparation supply unit and the exhaust control unit.

[0031] The control management unit is the upper computer, which stores the scheduled operation program of the simulation test, modifies the operation program and processe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com