Method of laser-beam welding machine for realizing local annealing

A technology of laser welding machine and partial annealing, which is applied in the direction of furnace types, furnaces, heat treatment furnaces, etc., can solve the problems of passing the flaring performance test, etc., and achieve the effects of stable product performance test, high yield rate, and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

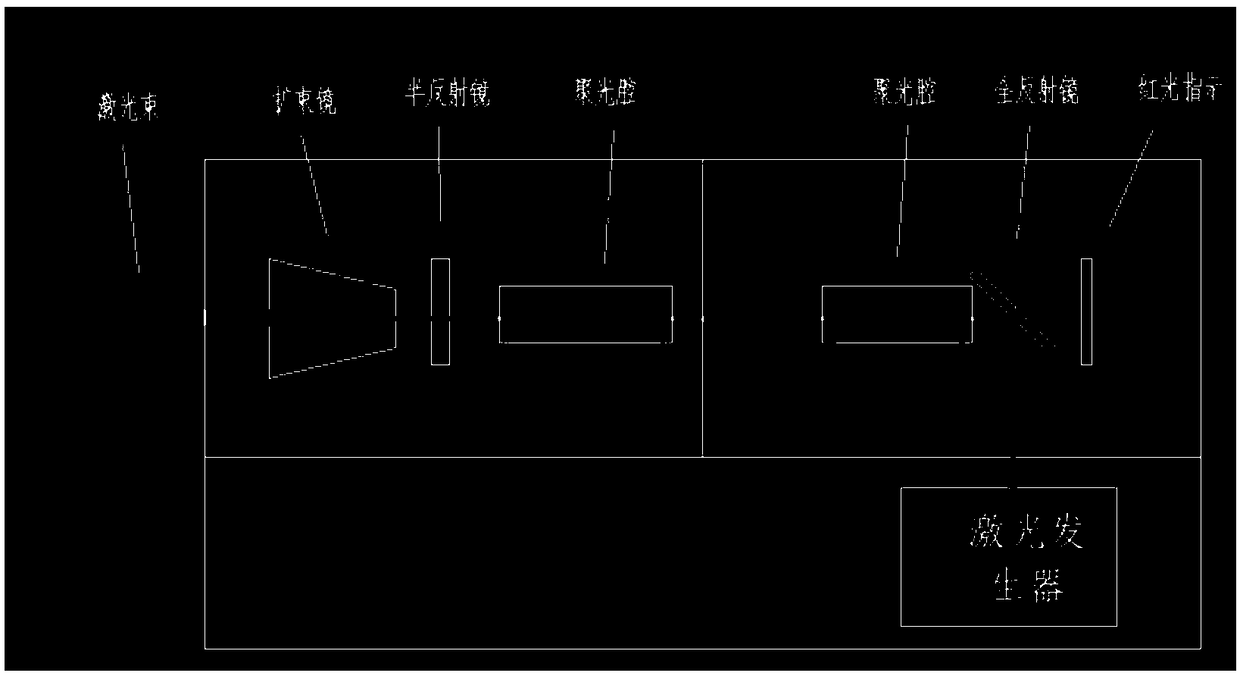

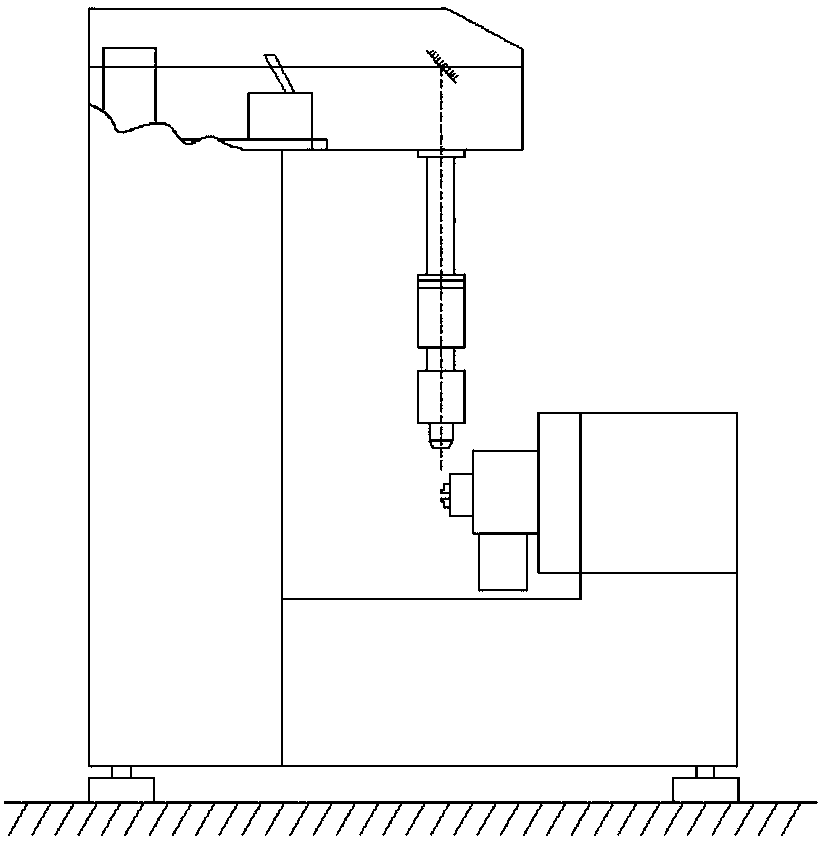

[0024] Take product XX.4.1401 as an example image 3 , the product requires the outer diameter of the local annealing section to be φ11-0.1mm, the aperture to be φ9.9+0.12mm, and the width of the rivet seat end to be 5.9±0.07mm. The calculation shows that the maximum wall thickness of the local annealing section is 0.55mm, and the minimum is 0.44mm, the rivet seat end is required to be 60° according to the standard, and the outer circle after flaring is 1.15 times of the original largest entity for riveting. The product must not have cracks. The implementation is as follows through the HJ-2 laser welding machine.

[0025] 1. Turn on the power and turn on the HJ-2 laser welding machine.

[0026] 2. Open the air valve to vacuumize the air cavity.

[0027] 3. When the air chamber reaches a vacuum state, close the air valve and perform vacuuming operation.

[0028] 4. Fill the air cavity with nitrogen, carbon dioxide and helium in proportion.

[0029] 5. Turn on the laser gener...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com