Modeling method for 38-lumping continuous reforming device reactor

A modeling method and reforming reaction technology, applied in the direction of naphtha catalytic reforming, instruments, special data processing applications, etc., to achieve the effect of improving accuracy, optimizing operating parameters, and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

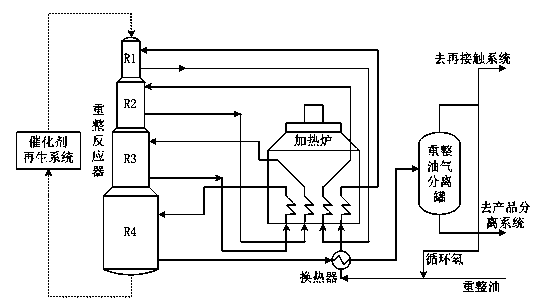

[0044] The present invention will be further described below in conjunction with accompanying drawing.

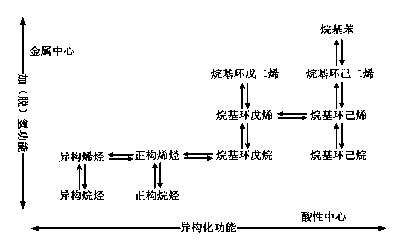

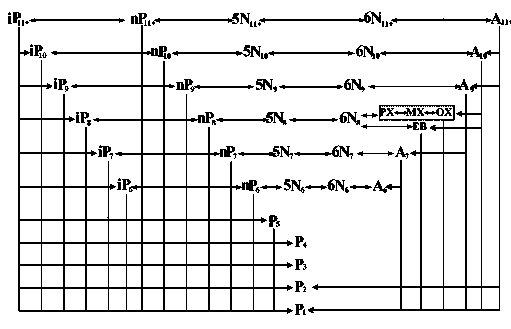

[0045] 1. Division of lumped components

[0046] Catalytic reforming is one of the most important industrial applications of catalysis. The reforming process has a complex catalytic reaction system. Whether the purpose is to produce high-octane gasoline components or aromatics, it is necessary to maximize the combination of paraffins and Naphthenes are converted to aromatics. The classic reforming reaction mechanism is the dual-functional reforming catalyst reaction mechanism proposed by Mills et al. (such as figure 1 ), it believes that the catalyst has two catalytic properties, one is metal performance, which plays the role of hydrogenation and dehydrogenation, and the other is acidic, which has the effect of isomerization. Alkenes are then cyclized at the acidic center to five-membered cycloalkanes, further isomerized to six-membered cycloalkanes, and finally dehydroge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com