A laser scanning annealing method using a hexagonal beam spot

A laser scanning and hexagonal technology, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of process deviation and insufficient precision of mechanical control system, so as to improve the uniformity of the whole chip, reduce the realization cost, The effect of reducing the difficulty of implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The invention provides a method for performing laser scanning annealing by using a hexagonal laser beam spot. Be described below in conjunction with accompanying drawing.

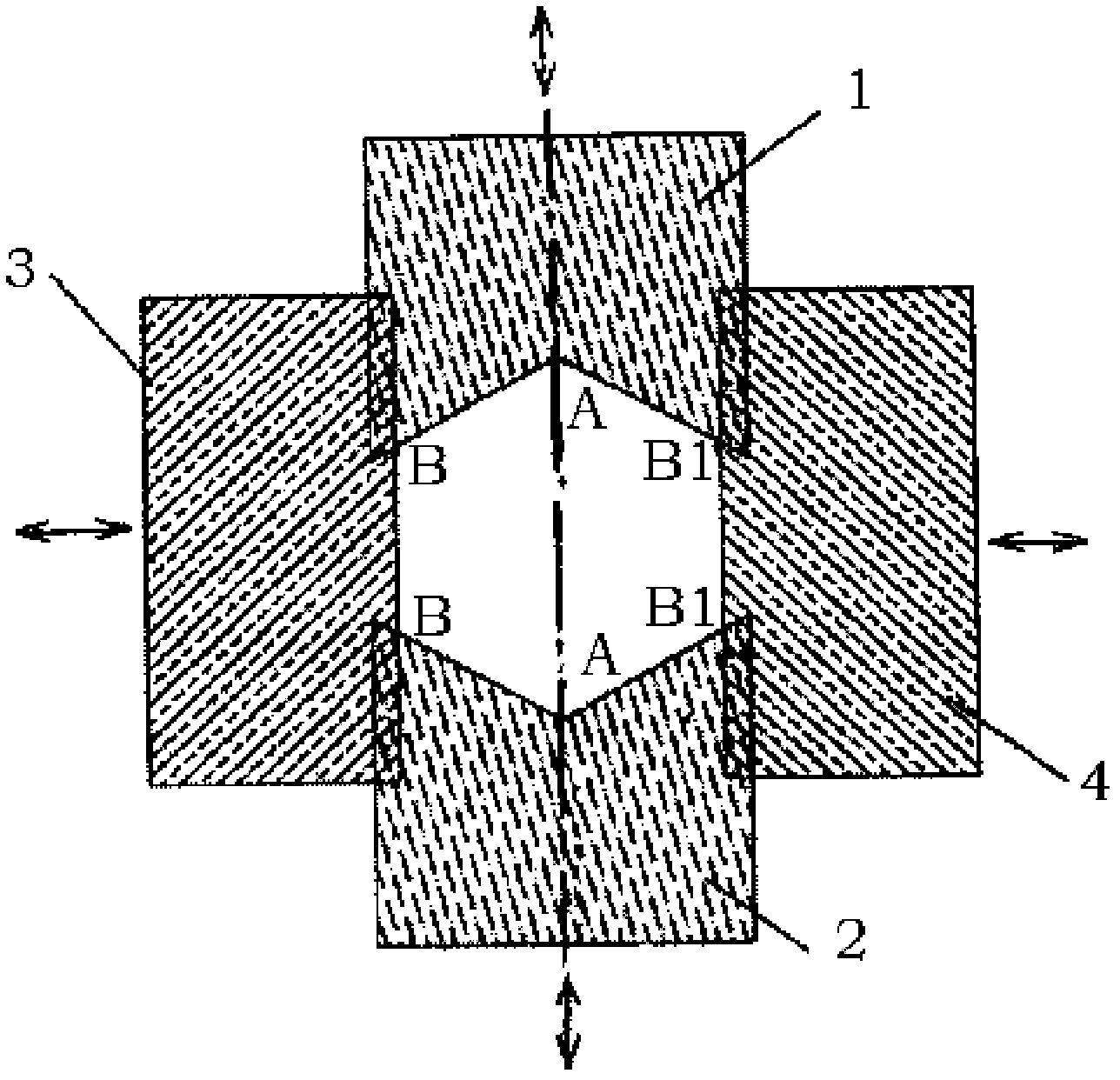

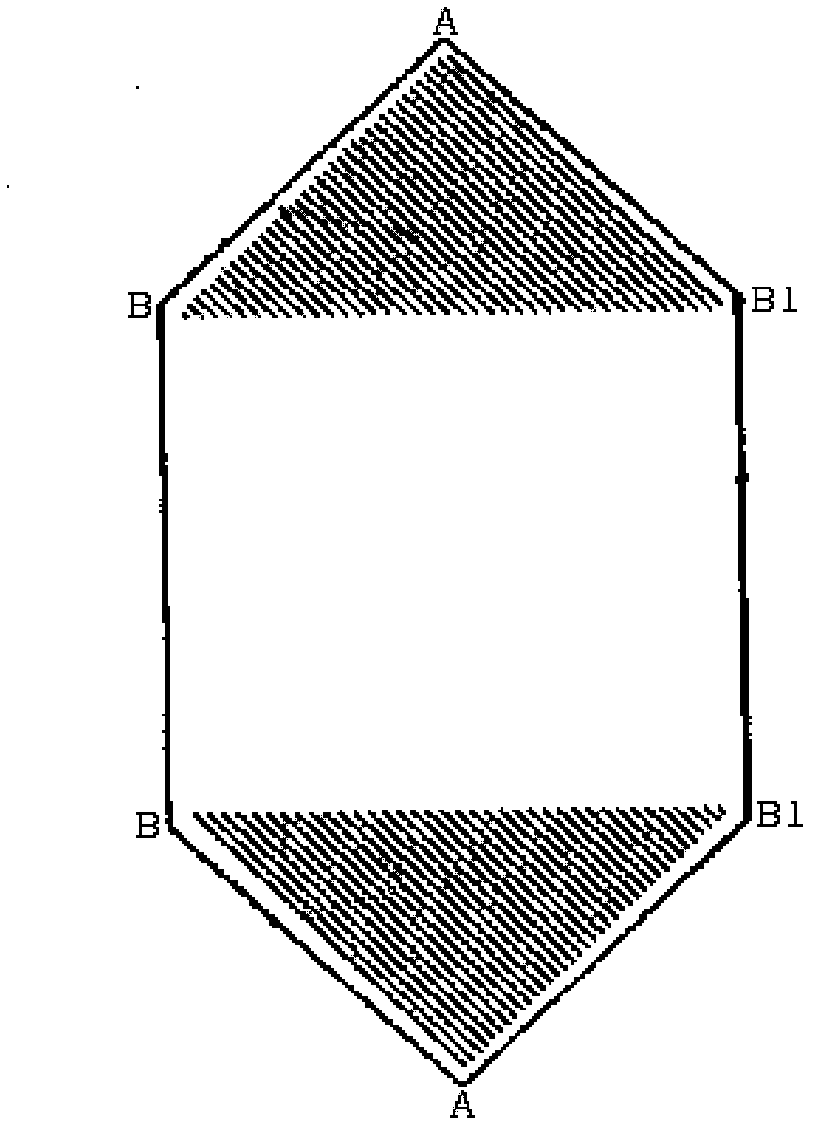

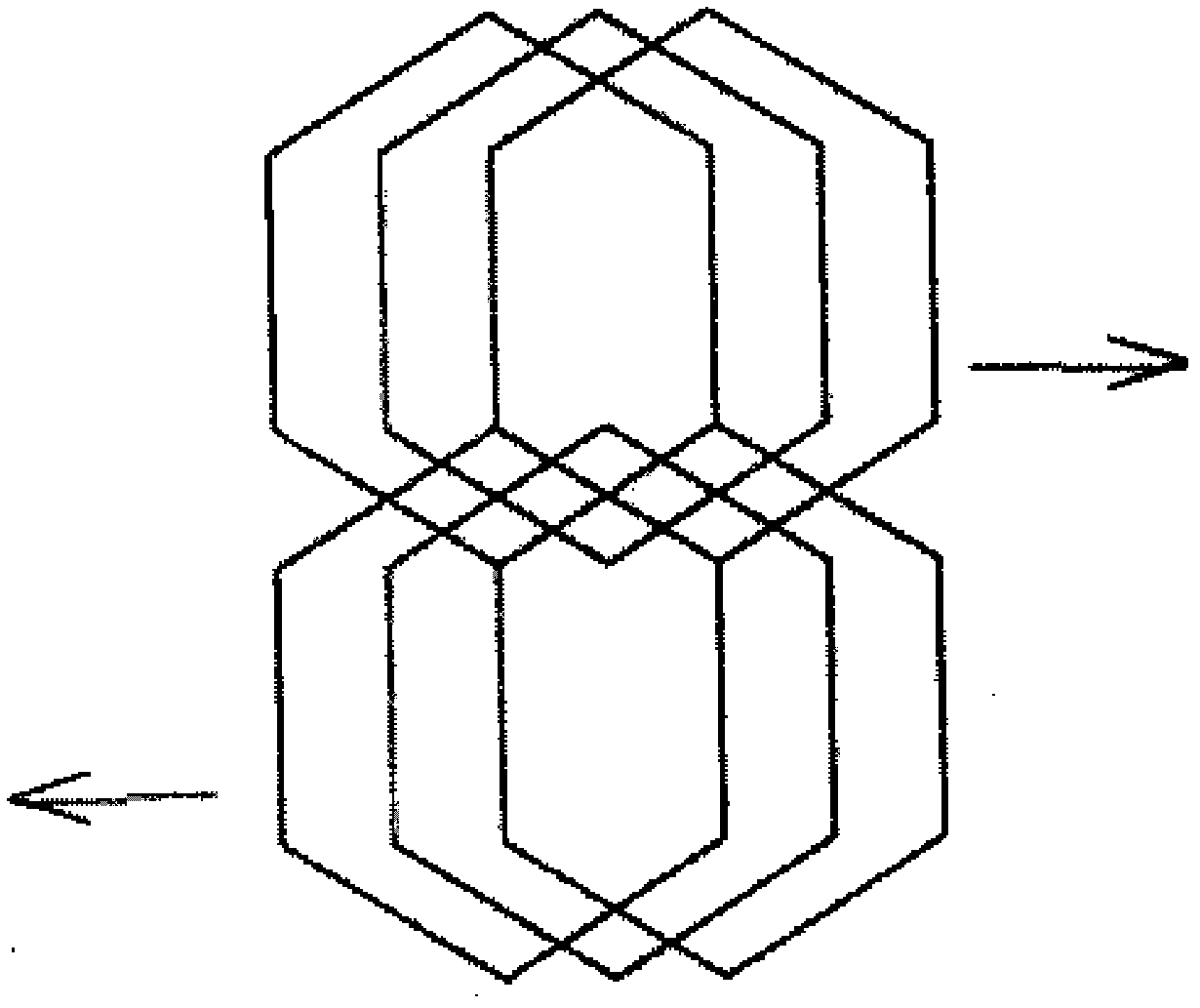

[0016] figure 1 Shown is a schematic diagram of the four-baffle mechanism forming a hexagonal beam spot. In the figure, the hexagonal laser beam spot, in the simplest case, is realized by four optical path baffles placed opposite each other in the optical path, that is, the baffle 1 and the baffle 2 are independent or move synchronously; the baffle 3 and the baffle 4 move independently or synchronously, and the four are all rectangular baffles, of which the upper baffle 1 and the lower baffle 2 or the opposite side of the left baffle 3 and the right baffle 4 , each opening a V-shaped opening to form a hexagonal vertex A, and the apex of the vertex A is on the center line; therefore, after the expanded and uniform laser beam passes through the baffle mechanism, the beam spot is hexagonal ABBAB1B1 ;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com