Mine explosion-proof and intrinsically safe drive center

An intrinsically safe and explosion-proof technology, applied in the field of motor speed control equipment and voltage conversion, it can solve the problems of incompatibility of the design principle of the front-stage switch, malfunction of the switch leakage protection, interference with normal operation, etc., to save energy. The effect of equipment installation space, elimination of failures, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

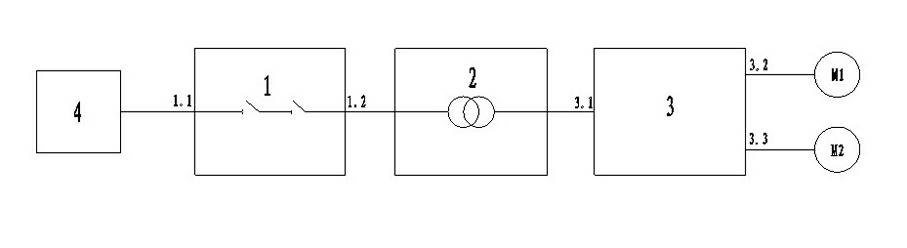

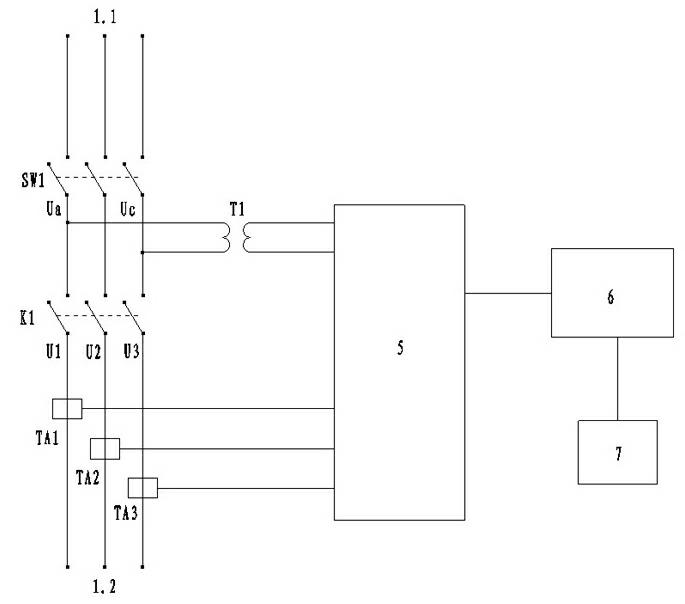

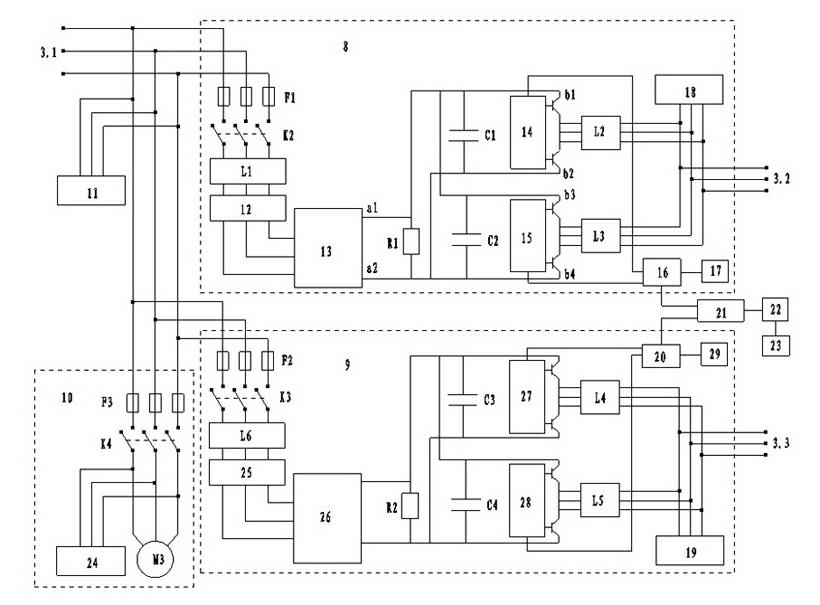

[0021] The mine explosion-proof and intrinsically safe drive center of the present invention includes: mine explosion-proof high-voltage vacuum power distribution device 1, mine mobile substation dry-type transformer 2 and mine explosion-proof and intrinsically safe frequency converter 3; The explosion-proof high-voltage vacuum power distribution device 1, the dry-type transformer 2 for mine mobile substation and the mine explosion-proof and intrinsically safe frequency converter 3 are respectively arranged in three independent explosion-proof boxes; the three explosion-proof boxes In turn through the flange connection;

[0022] The inlet terminal 1.1 of the mine explosion-proof high-voltage vacuum power distribution device 1 is connected to the output high-voltage power supply 4 of the substation in the underground area, and the outlet terminal 1.2 of the mine explosion-proof high-voltage vacuum power distribution device 1 is connected to the mine mobile substation. The input...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com