Three-phase synchronous deicing device for transmission line

A three-phase synchronization, transmission line technology, applied in the installation, transportation and packaging of cables, electrical components, etc., can solve the problems of life safety, slow progress, and narrow promotion, and achieve the effect of ensuring normal work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

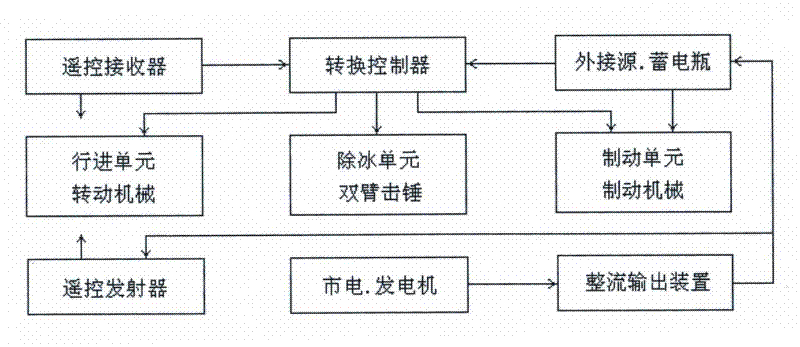

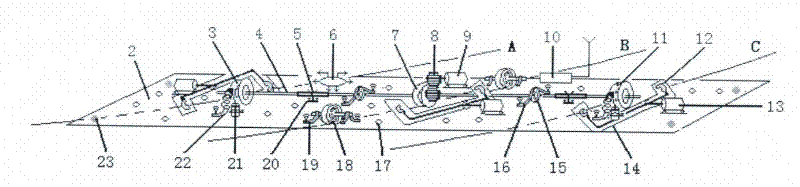

[0031] The three-phase synchronous de-icing device is composed of a robot arm and an electrical control, and the structure is as follows: figure 1 .

[0032] From figure 1 It can be seen in the figure: the ground can transmit various signals such as advancing, reversing, and hitting through the remote control. After receiving the remote control signal, the high-altitude cable deicing device performs sorting and conversion, and sends control signals to each unit to implement specific functions. The traveling unit is composed of a main motor, transmission gear, transmission shaft, etc.; the deicing unit is composed of a 180° rotating motor, a swing arm, and a double-click hammer; the braking unit is composed of a return spring, a brake pad and a braking motor; the working power supply can be provided by the market. Electricity or gasoline generators are provided from the ground, and storage batteries can also be provided to avoid long pull wires.

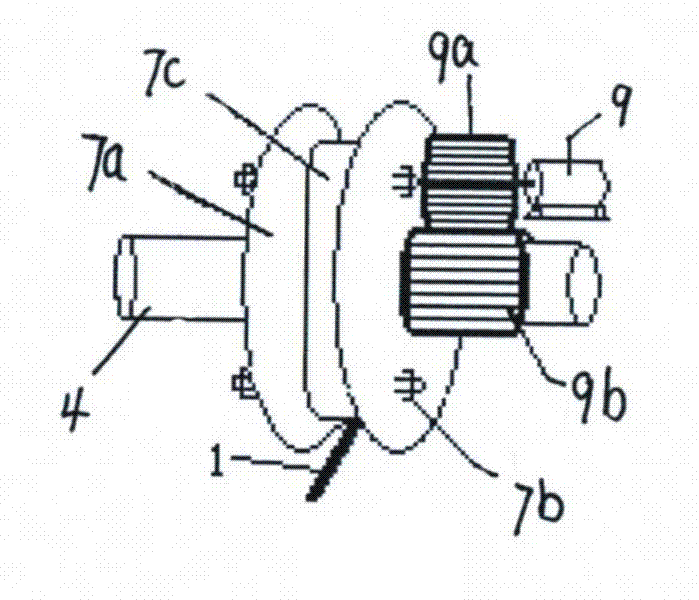

[0033] The three-phase synch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com