Processing equipment and method for industrialized production of dried cheese

A processing equipment and cheese drying technology, which is applied in cheese substitutes, dairy products, applications, etc., can solve the problems of poor product quality stability and food safety, poor product quality stability, and low quality management level, so as to ensure stability and food safety, shorten production time, and improve the effect of processing automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

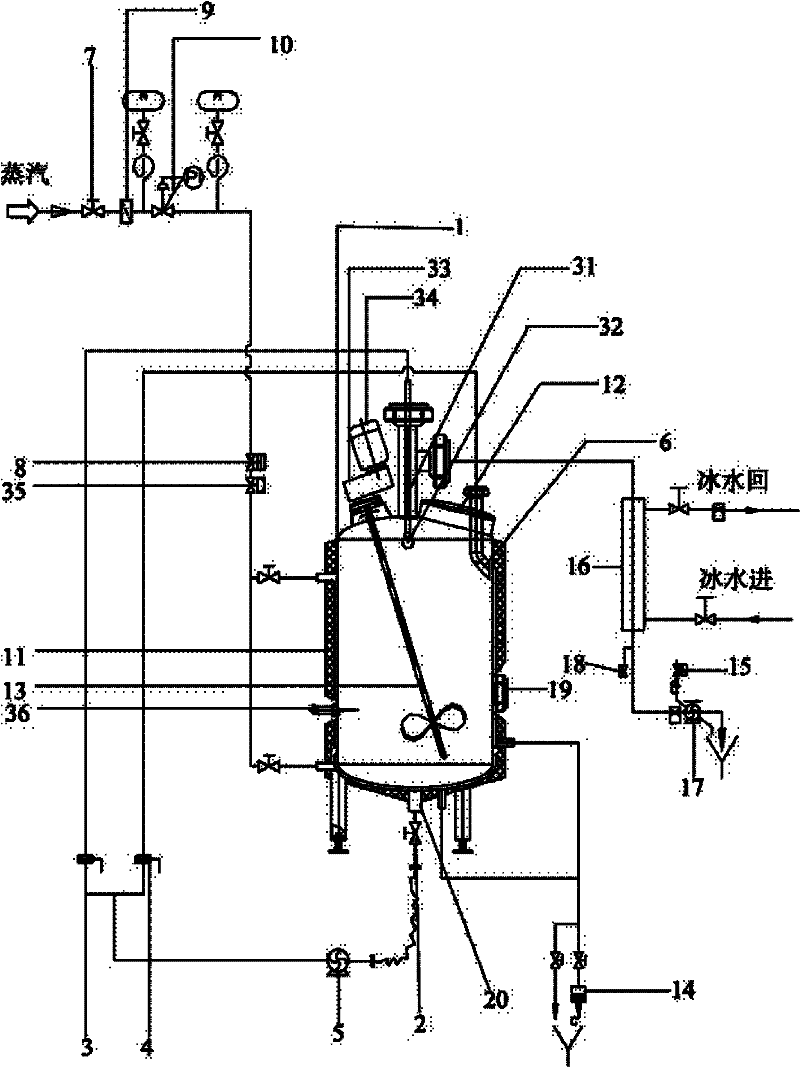

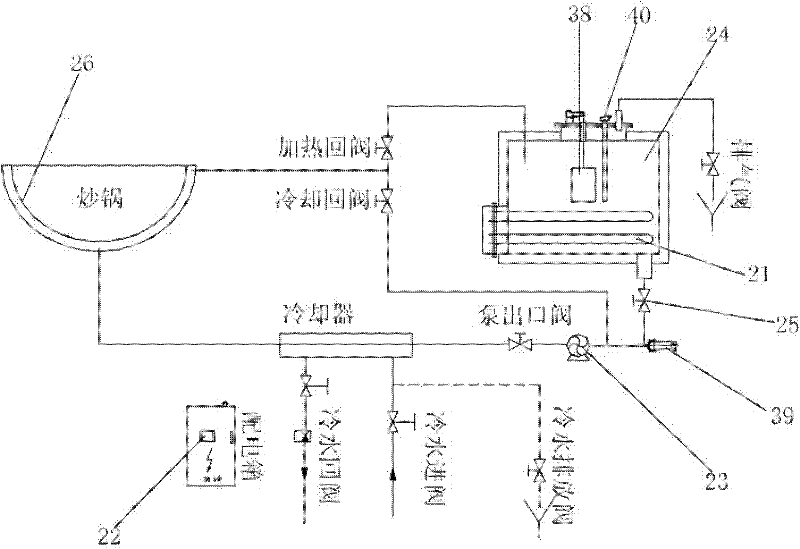

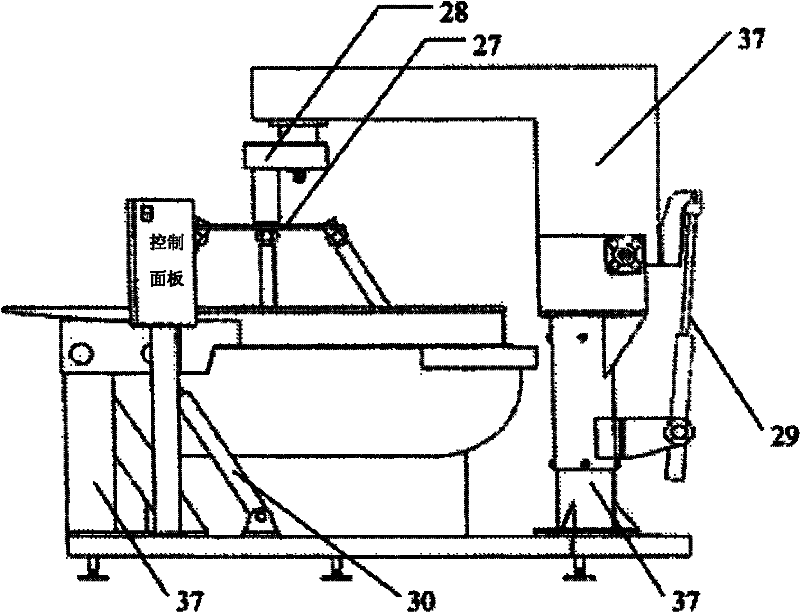

[0038] like figure 1 , figure 2 , image 3 As shown, the processing equipment of the present invention includes a concentration tank unit and an electric oil heating wok unit located on the right side of the concentration tank unit.

[0039]The concentration tank unit includes a concentration tank 1, a heating control system, and a vacuum concentration system communicated with the concentration tank 1. The concentration tank 1 is a closed interlayer tank, which includes a manhole cover 12 , a three-leaf spiral agitator 13 , and a liquid level sight glass 19 . The concentration tank 1 is provided with a material inlet 6 and a material outlet 20 , a spray pipe 31 , a ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com