Conformal Forging Forming Technology of Hemispherical Head

A forging forming and hemispherical technology, applied in the field of forging and pressing, can solve the problems of large cutting amount, long processing cycle and high manufacturing cost, and achieve the effects of small machining allowance, short processing cycle and low manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In the following, the conformal forging forming process of the hemispherical head of the present invention will be further described in conjunction with the examples of the above-mentioned drawings.

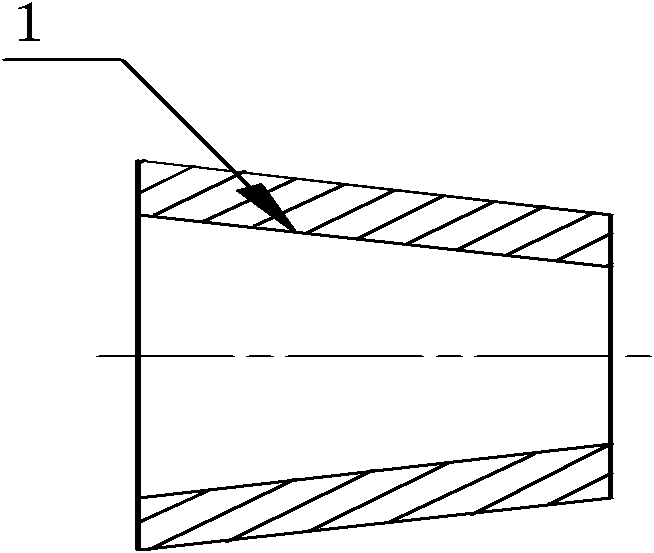

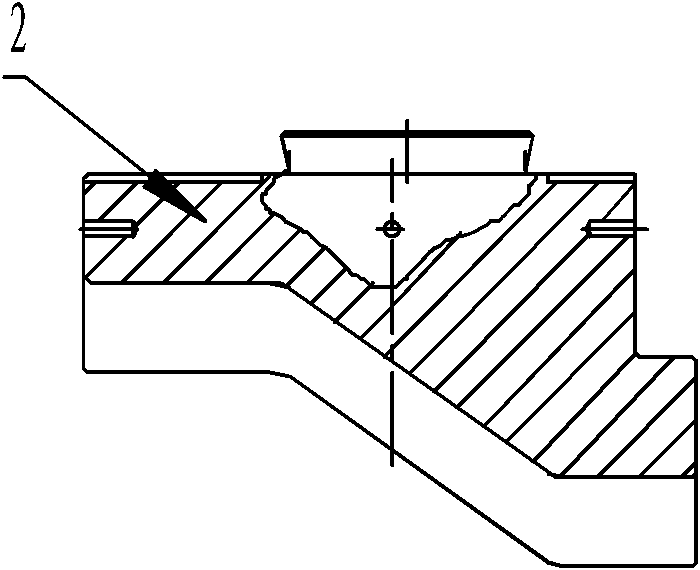

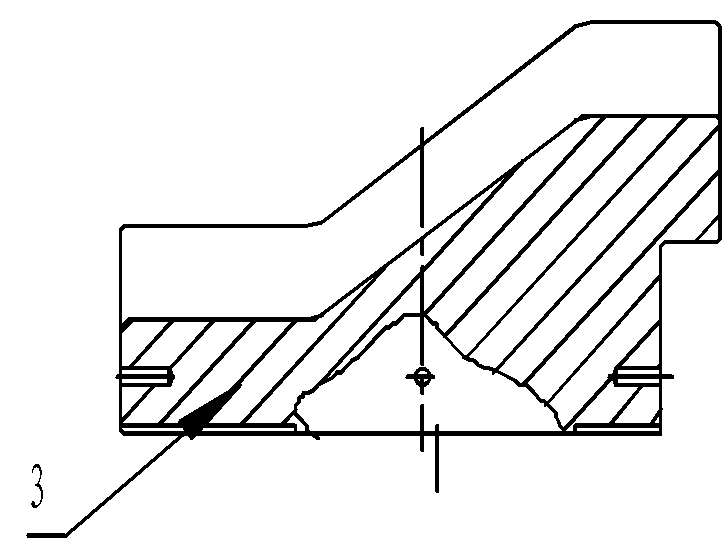

[0011] An example of the conformal forging process of the hemispherical head of the present invention includes a conical cylinder 1 , an upper die 2 , a lower die 3 , and a hemispherical head 4 .

[0012] The hemispherical head follow-the-shape forging molding process of the present invention, it forges the cylindrical body through steel ingot blanking, upsetting, elongating, punching, and then uses horse frame, mandrel, and adjusts the pressure angle of the upper anvil and After the strength is applied, the conical cylinder 1 is forged, the upper mold 2 and the lower mold 3 are preheated at 300-400°C, the conical cylinder 1 is heated at 1150-1200°C, and the lower mold 3 is placed in the press. On the platform, lift the conical cylinder 1 with a mandrel and place it on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com