A method for reinforcing carbon fibers

A carbon fiber, strength technology, applied in the direction of carbon fiber, fiber processing, fiber chemical characteristics, etc., can solve the problem of "repair" efficiency is not ideal and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~12

[0020] 1. Preparation of spraying liquid:

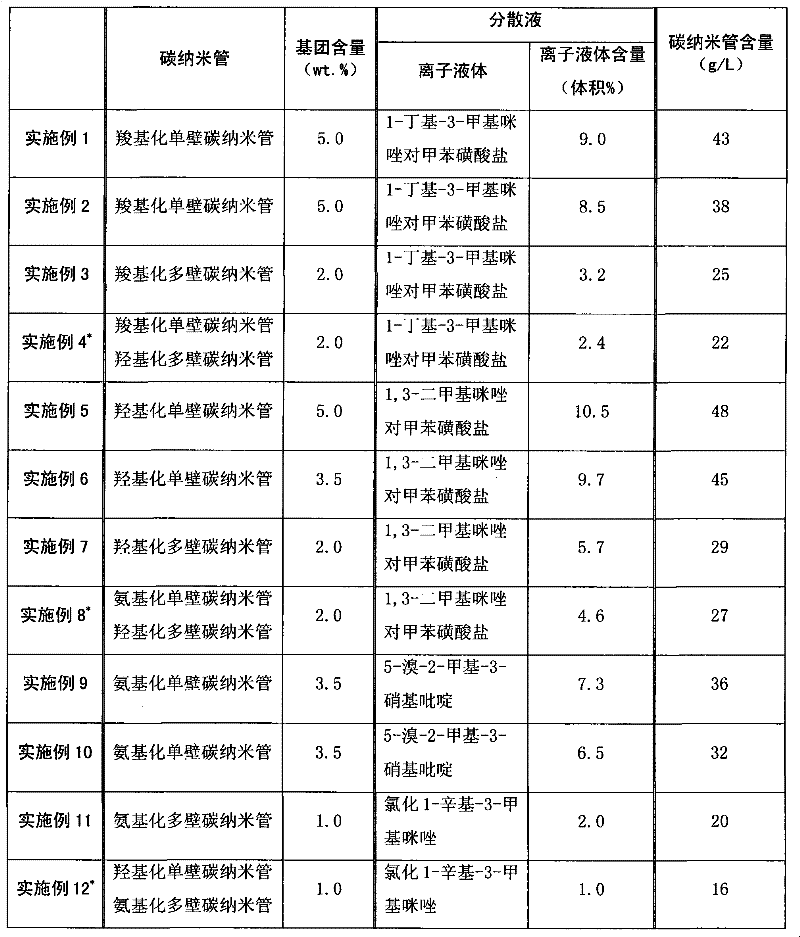

[0021] Take the commercially available functionalized carbon nanotubes and the dispersion prepared by ionic liquid and water, mix them in a container according to the required ratio, and then use ultrasonic waves with a frequency of 25kHz to perform ultrasonic vibration for about 5 hours to make the carbon nanotubes The tube is fully dispersed in the dispersion liquid, and then prepared into the spray liquid of the required concentration for later use. The composition of the spraying liquid in each embodiment is shown in Table 1. The diameter distribution of the single-wall carbon nanotubes used is 0.5-5 nm, the diameter distribution of the multi-wall carbon nanotubes is 10-20 nm, and the length distribution is 10-30 μm.

[0022] Table 1.

[0023]

[0024] *The weight ratio of single-walled carbon nanotubes to multi-walled carbon nanotubes is 1:1.

[0025] 2. Electrostatic spraying of carbon nanotubes on the surface of carbon fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com