Bearing system hybrid combined girder cable-stayed bridge and its construction method

A hybrid and combined beam technology, used in cable-stayed bridges, bridges, bridge forms, etc., can solve problems such as failure to meet force requirements, improve wind resistance and other safety factors, use less materials, and enrich the main tower. modeling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

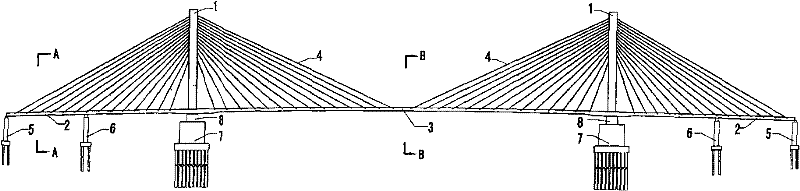

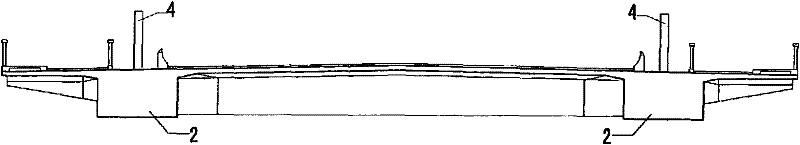

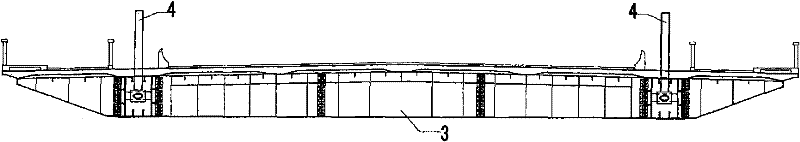

[0022] refer to figure 1 , 2 , 3, side-span concrete beam 2 is poured on the side pier 5 and auxiliary pier 6 of the present invention, stay cables 4 are hung on the mid-span joint beam 3, and large-tonnage spherical steel is arranged between the two main towers 1 and the main tower pier 7 Bearing 8, two large tonnage spherical steel bearings 8 construction mid-span combined beam 3.

[0023] refer to figure 1 , 2 , 3, the concrete steps of the present invention are as follows:

[0024] a. First construct the foundation of the main tower pier 7, auxiliary pier 6, and side pier 5, and then construct the pier body,

[0025] b. Lift the large-tonnage spherical steel support 8 onto the main tower pier, pour the side-span concrete beam 2 that is consolidated with the main tower, and complete the temporary consolidation of the main tower pier and the side-span concrete beam,

[0026] c. While carrying out the construction of the main tower 1, pour the remaining side-span concret...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com