An acceleration sensor chip with a composite multi-beam structure and its manufacturing method

An acceleration sensor and beam structure technology, applied in the direction of acceleration measurement using inertial force, microstructure technology, microstructure device, etc., can solve the problems of dynamic measurement of vibration acceleration, reduce the reliability of the sensor, and reduce the output of the sensor, etc., to achieve Facilitate cost reduction, anti-corrosion bonding properties, and good bonding properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in more detail below in conjunction with the accompanying drawings.

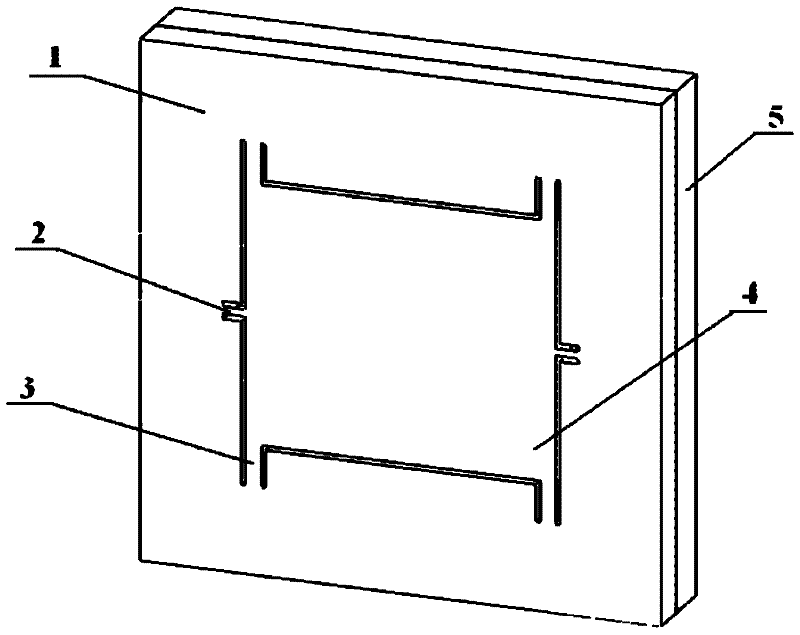

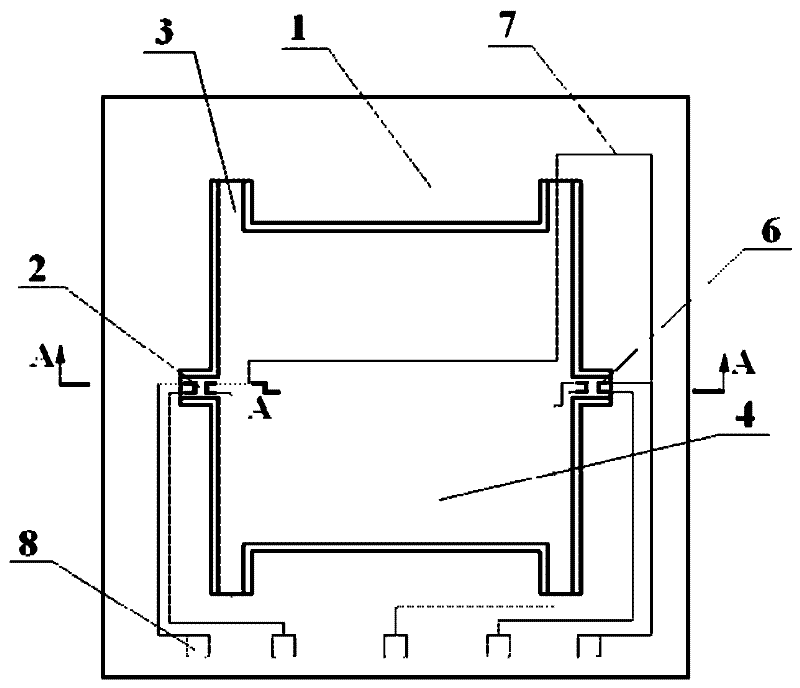

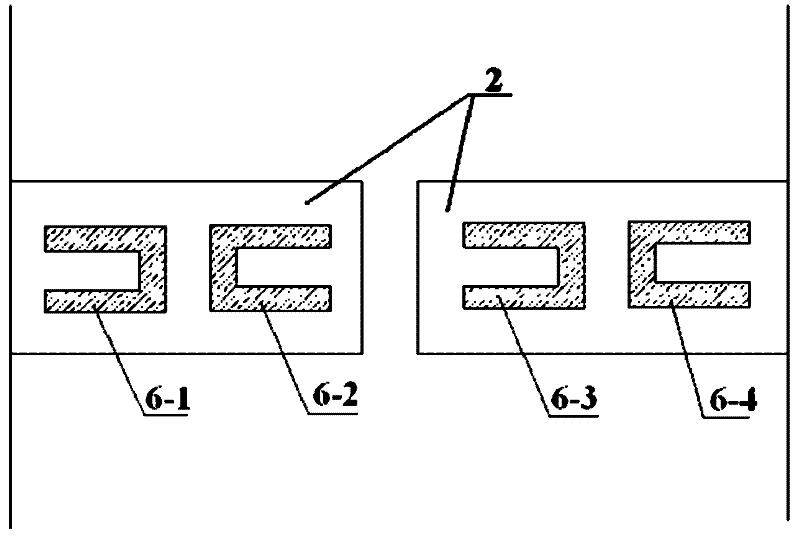

[0028] refer to figure 1 , an acceleration sensor chip with a composite multi-beam structure, comprising a silicon substrate 1, the back of which is bonded to boron glass 5, a suspended mass 4 is arranged in the central cavity of the silicon substrate 1, four identical support beams 3 two Two groups are connected to one set of opposite sides of the suspended mass 4, and two identical sensitive beams 2 are respectively connected to the other set of opposite sides of the suspended mass 4, and the support beam 3 and the sensitive beam 2 jointly support the suspended mass 4, so that It remains in a suspended state, boron glass 5 is bonded to the back of silicon substrate 1, and a working gap is reserved with the bottom surface of suspended mass 4 to ensure that suspended mass 4 can always be suspended in the air when the sensor is working normally, and in some overl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com