Method and device for improving operation accuracy of electric cylinder and electric cylinder

A technology of electric cylinder and running direction, which is applied in the direction of electromechanical devices, measuring devices, electric components, etc. It can solve the problems of difficult to guarantee the accuracy requirements, the inability to read the grating data correctly, and the inability of the electric cylinder to run and position accurately, so as to achieve high-speed operation and positioning accuracy, and improve the effect of running accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

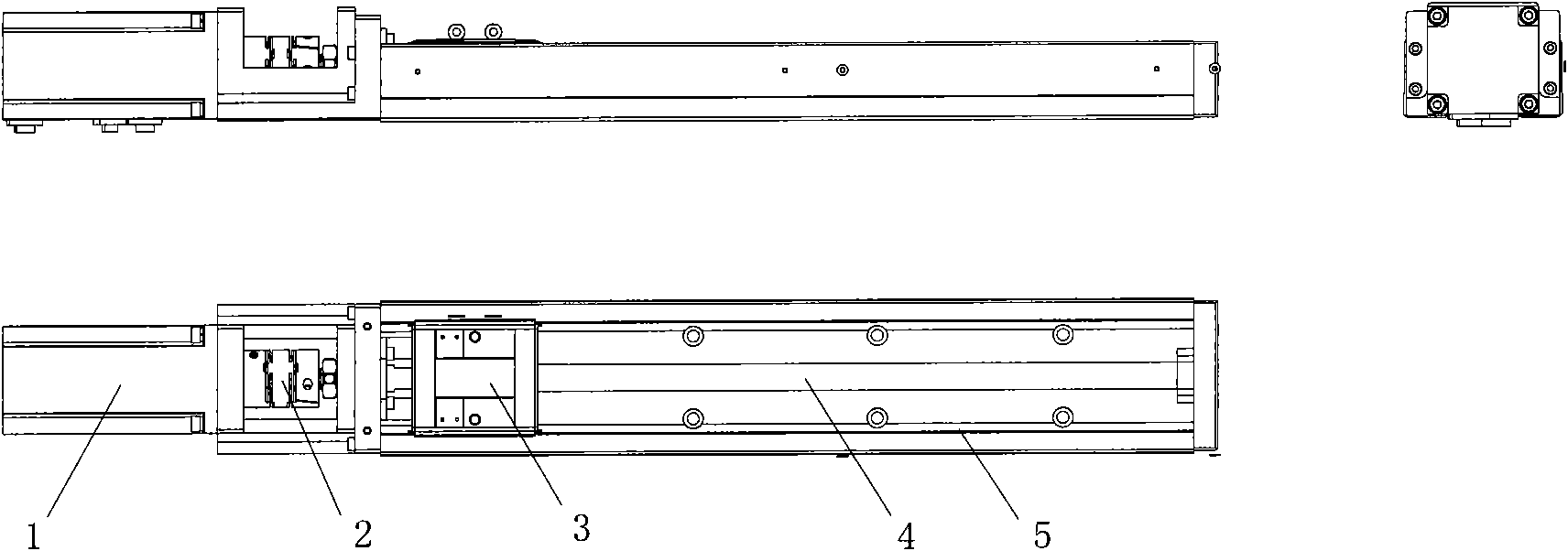

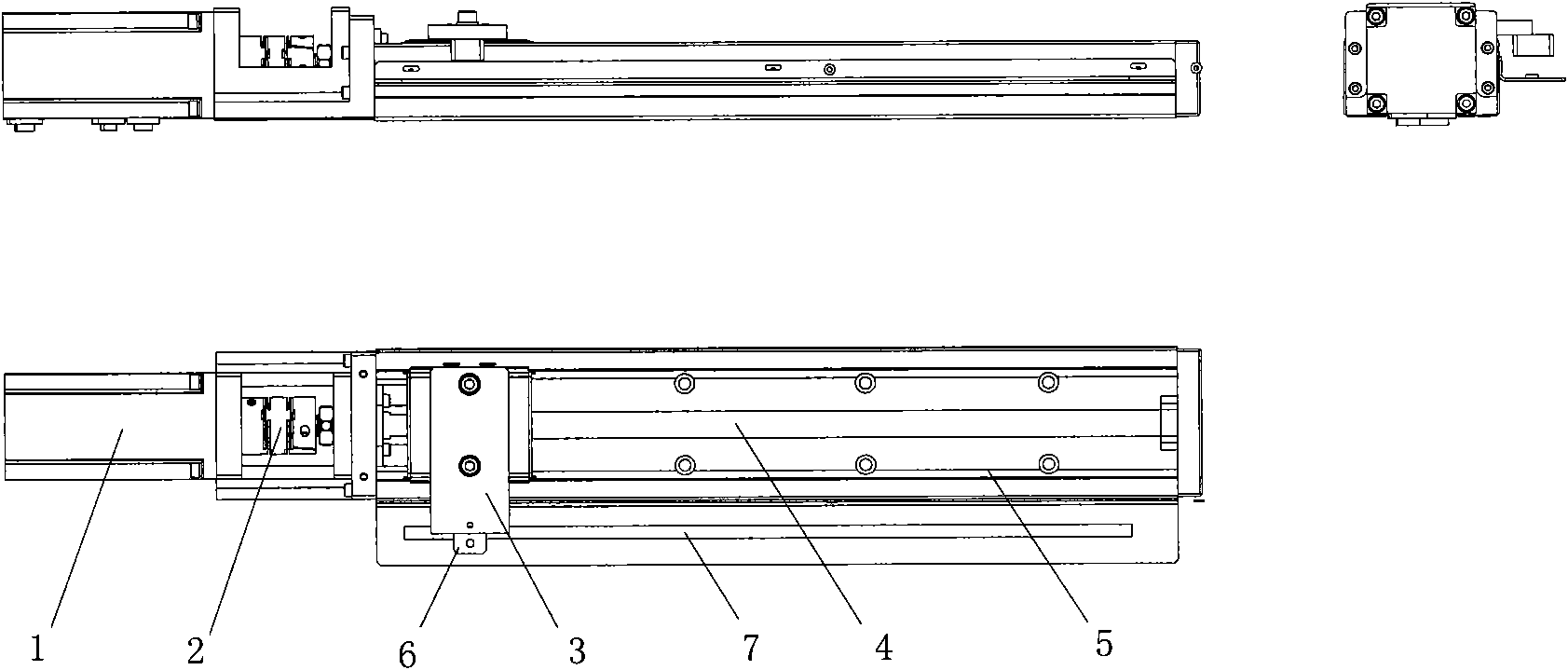

[0034] In order to enable those skilled in the art to better understand the technical solution of the present invention, the method, device and electric cylinder provided by the present invention for improving the operating accuracy of the electric cylinder will be described in detail below with reference to the accompanying drawings.

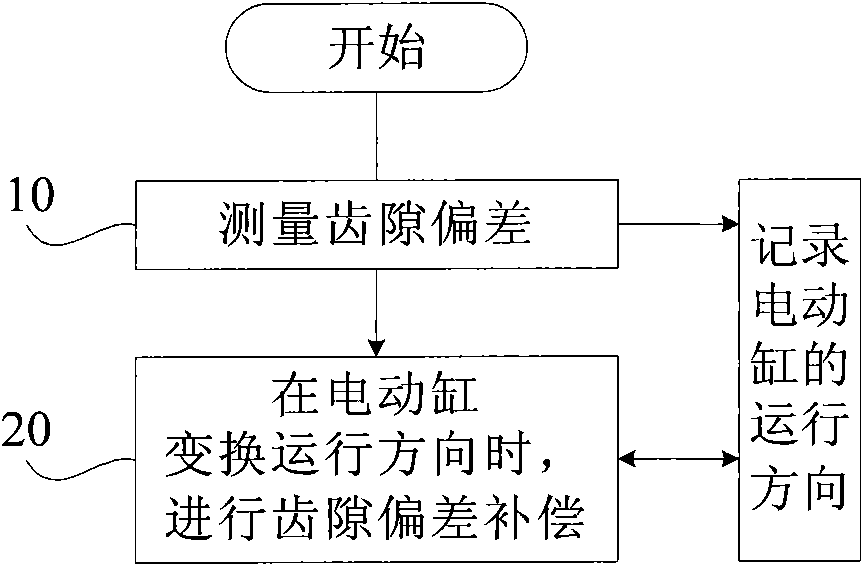

[0035] see image 3 , is a flow chart of the method for improving the running accuracy of the electric cylinder provided by the present invention. The method comprises the following steps: 10) Obtain the measured value of the backlash in the electric cylinder by measuring, and obtain the backlash deviation of the electric cylinder based on the measured value of the backlash and the set value of the backlash; 20) During the operation of the electric cylinder , when the electric cylinder changes the running direction, the backlash deviation compensation is implemented according to the backlash deviation, so as to improve the running accuracy of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com