Electromagnetic induction heating device and method thereof

An electromagnetic induction heating and electric energy technology, applied in induction heating, induction heating control, etc., can solve the problems of heating power and efficiency reduction, inconvenience, high cost, etc., and achieve good transient performance and steady-state performance, high precision and response sensitivity , High heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure and characteristics of the electromagnetic induction heating device and its method according to the present invention will be described below in conjunction with the accompanying drawings and preferred embodiments. and its efficacy are described in detail below.

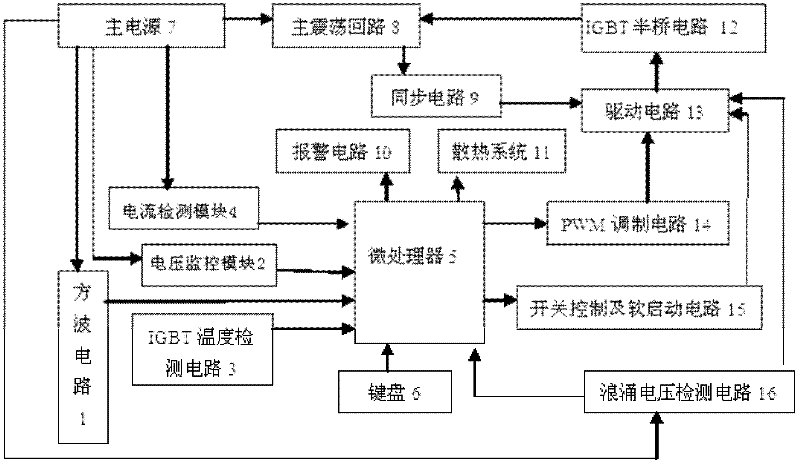

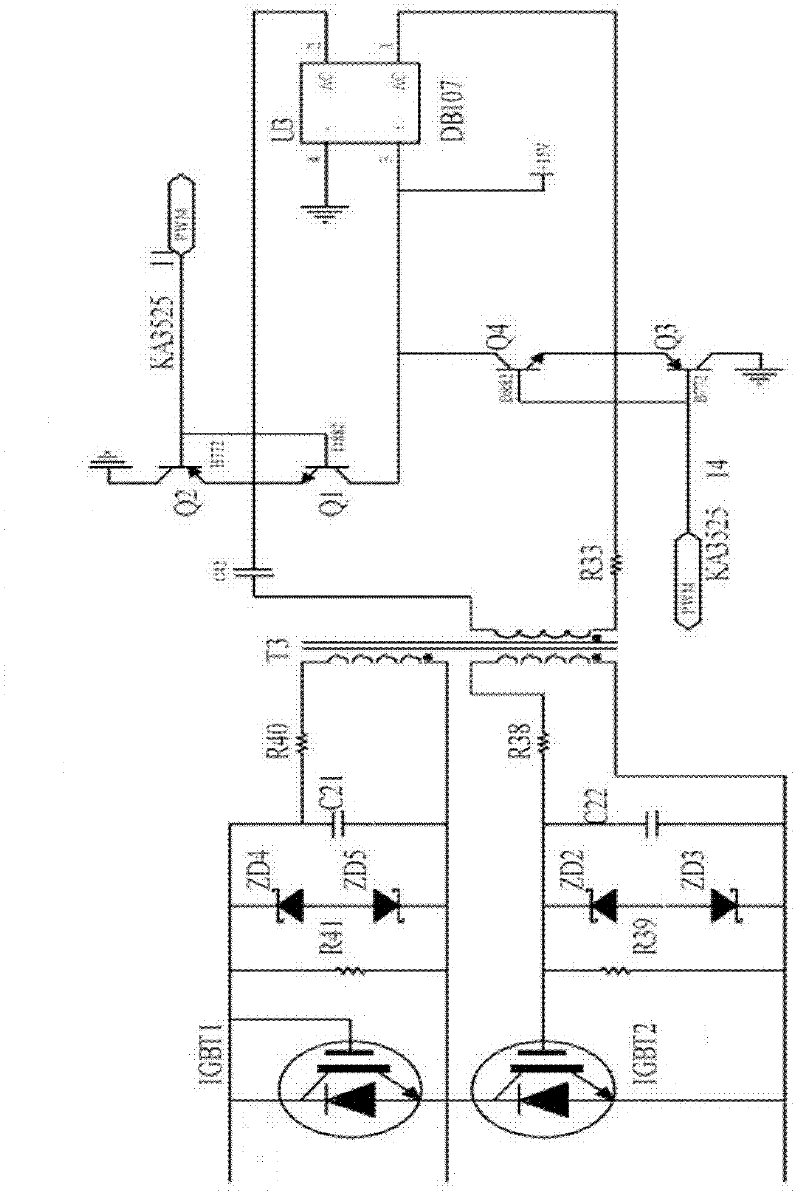

[0044] Such as figure 1As shown, the electromagnetic induction heating device includes a microprocessor 5, a keyboard 6, a main power supply 7, a main oscillation circuit 8, a synchronization circuit 9, an alarm circuit 10, a cooling system 11, an IGB half-bridge circuit 12, a drive circuit 13, a modulation circuit and Protection module, the protection module includes a current detection module 4, a voltage monitoring module 2, an IGBT temperature detection circuit 3 and a surge voltage detection circuit 16, the modulation circuit includes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resonant frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com