High-efficiency seed soaking agent for sugarcanes and preparation method thereof

A seed soaking agent and high-efficiency technology are applied in the field of multi-functional and high-efficiency seed soaking agent and its preparation, which can solve the problems of low germination rate, affecting the yield and quality of sugarcane, low seedling emergence rate, etc. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

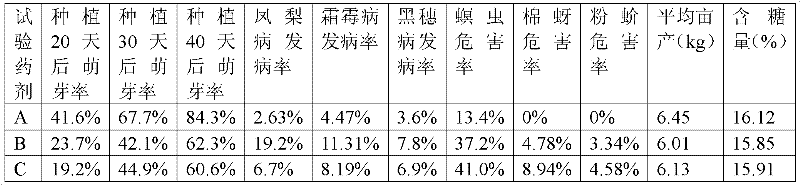

Image

Examples

Embodiment 1

[0017] A high-efficiency seed soaking agent for sugarcane, comprising the following steps:

[0018] ① Weigh 150 mg of 6-benzylaminopurine, 1.5 g of potassium indolebutyrate, 150 g of thiophanate-methyl, 150 g of trichlorfon, and 150 g of high-efficiency chelating additives;

[0019] ② Pour the weighed 6-benzylaminopurine, potassium indolebutyrate, thiophanate-methyl, and trichlorfon into a mixer and mix for 20 minutes, and mix well to obtain a mixture;

[0020] 3. the mixture obtained in step 2. is packed into a sealed pulverizer for pulverization, and the pulverized mixture passes through a 100-mesh sieve;

[0021] 4. Put the pulverized mixture in the step 3. into the chelator again, and while stirring, spray the high-efficiency chelating auxiliary agent into the chelator by spraying for chelation. After 15 minutes of chelation, you can get Soaking agent.

[0022] Wherein, the high-efficiency chelating auxiliary agent used includes the following components in parts by weigh...

Embodiment 2

[0024] A high-efficiency seed soaking agent for sugarcane, comprising the following steps:

[0025] ① Weigh 100 mg of 6-benzylaminopurine, 2 g of potassium indolebutyrate, 200 g of thiophanate-methyl, 100 g of trichlorfon, and 200 g of high-efficiency additives;

[0026] ② Pour the weighed 6-benzylaminopurine, potassium indolebutyrate, thiophanate-methyl, and trichlorfon into a mixer and mix for 20 minutes, and mix well to obtain a mixture;

[0027] 3. the mixture obtained in step 2. is packed into a sealed pulverizer for pulverization, and the pulverized mixture passes through a 100-mesh sieve;

[0028] 4. Put the crushed mixture in the step 3. into the chelator again, and while stirring, spray the high-efficiency chelating auxiliary agent into the chelator by spraying for chelation. After 15 minutes of chelation, you can get Soaking agent.

[0029] Wherein, the high-efficiency chelating auxiliary agent used includes the following components in parts by weight: 70 parts of ...

Embodiment 3

[0031] A high-efficiency seed soaking agent for sugarcane, comprising the following steps:

[0032] ① Weigh 250 mg of 6-benzylaminopurine, 1 g of potassium indolebutyrate, 100 g of thiophanate-methyl, 200 g of trichlorfon, and 100 g of high-efficiency additives;

[0033] ② Pour the weighed 6-benzylaminopurine, potassium indolebutyrate, thiophanate-methyl, and trichlorfon into a mixer and mix for 20 minutes, and mix well to obtain a mixture;

[0034] 3. the mixture obtained in step 2. is packed into a sealed pulverizer for pulverization, and the pulverized mixture passes through a 100-mesh sieve;

[0035] 4. Put the crushed mixture in the step 3. into the chelator again, and while stirring, spray the high-efficiency chelating auxiliary agent into the chelator by spraying for chelation. After 15 minutes of chelation, you can get Soaking agent.

[0036] Wherein, the high-efficiency chelating auxiliary agent used includes the following components in parts by weight: 65 parts of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com