Cement grinding roller with bionic coupling wear-resistant surface layer and preparation method thereof

A cement grinding and wear-resistant layer technology, applied in grain processing and other directions, can solve the problems of low repair processing efficiency, difficult material processing, large repair processing volume, etc., to promote the growth of the national economy, wear resistance and powder. The effect of improved grinding effect and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

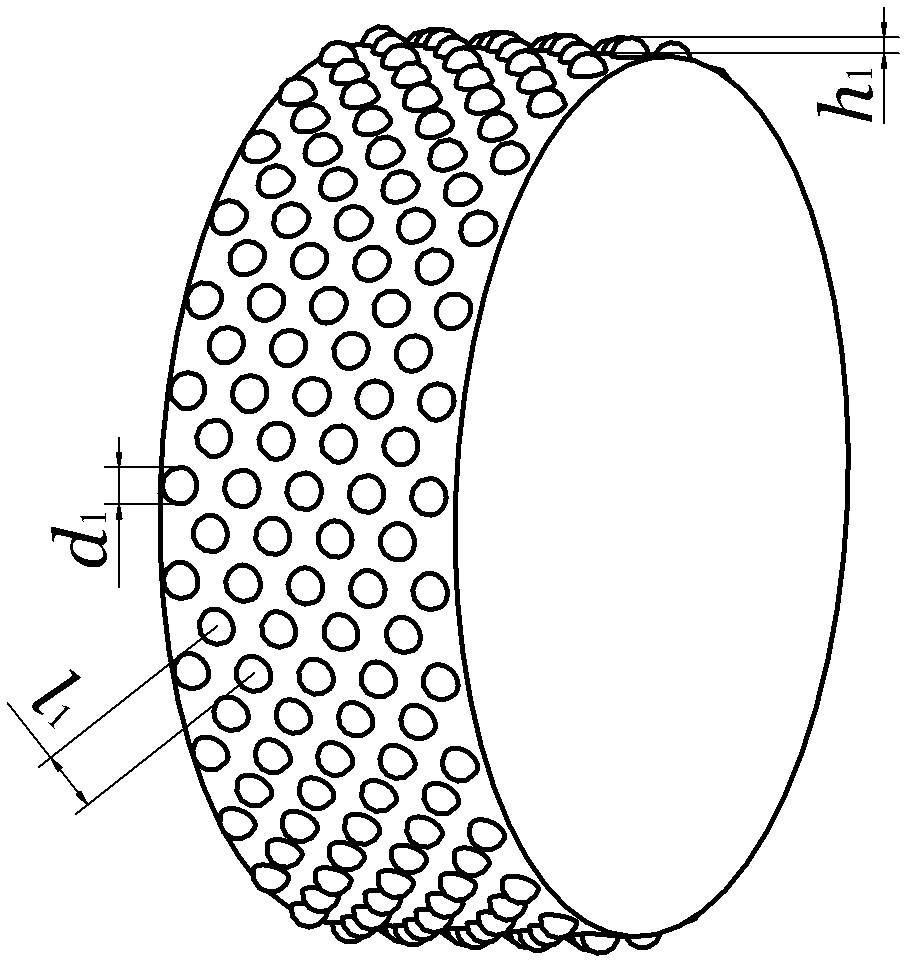

[0038] see figure 1 , a cement grinding roller with a convex hull bionic coupling wear-resistant surface layer, the core material is 45 medium carbon steel, and the transition layer of the grinding roller is high-chromium and high-manganese austenite with different components (wt%) according to three different thicknesses Body welding material surfacing welding.

[0039] The surface of the grinding roller is processed into three bionic coupling strengthening layers with convex hulls with different sizes and distributions by surfacing welding technology. Its material is high chromium cast iron wear-resistant welding wire with different components (wt%).

[0040] The material composition of the wear-resistant layer is the same as that of the bionic coupling strengthening layer, and is made of welding material surfacing according to three different thicknesses of the wear-resistant layer.

[0041] The parameters of the transition layer, wear-resistant layer and bionic coupling ...

Embodiment 2

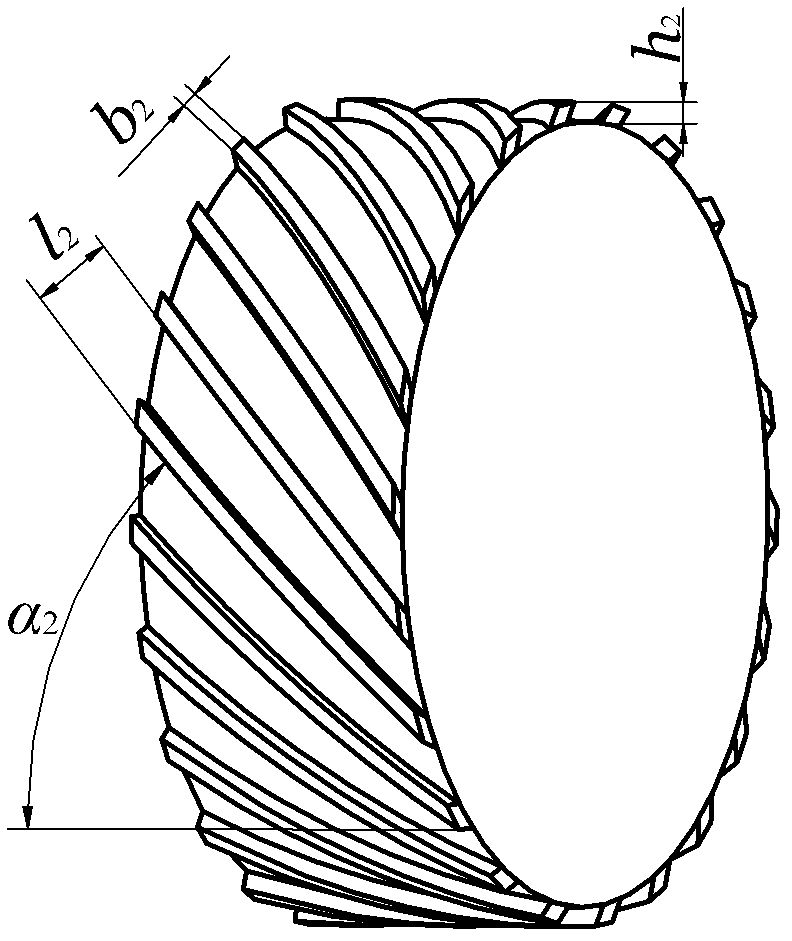

[0045] see figure 2 , cement grinding roller with striped bionic coupling wear-resistant surface layer, the core material is 45 medium carbon steel, and the transition layer of the grinding roller is high chromium and high manganese austenite with different components (wt%) according to three different thicknesses Welding materials are surfacing.

[0046] The surface of the grinding roller is processed into three bionic coupling strengthening layers with stripes of different sizes and distributions by surfacing technology. Its material is high chromium cast iron wear-resistant welding wire with different components (wt%).

[0047] The material composition of the wear-resistant layer is the same as that of the bionic coupling strengthening layer, and is made of welding material surfacing according to three different thicknesses of the wear-resistant layer.

[0048] The parameters of the transition layer, wear-resistant layer and bionic coupling strengthening layer of the bio...

Embodiment 3

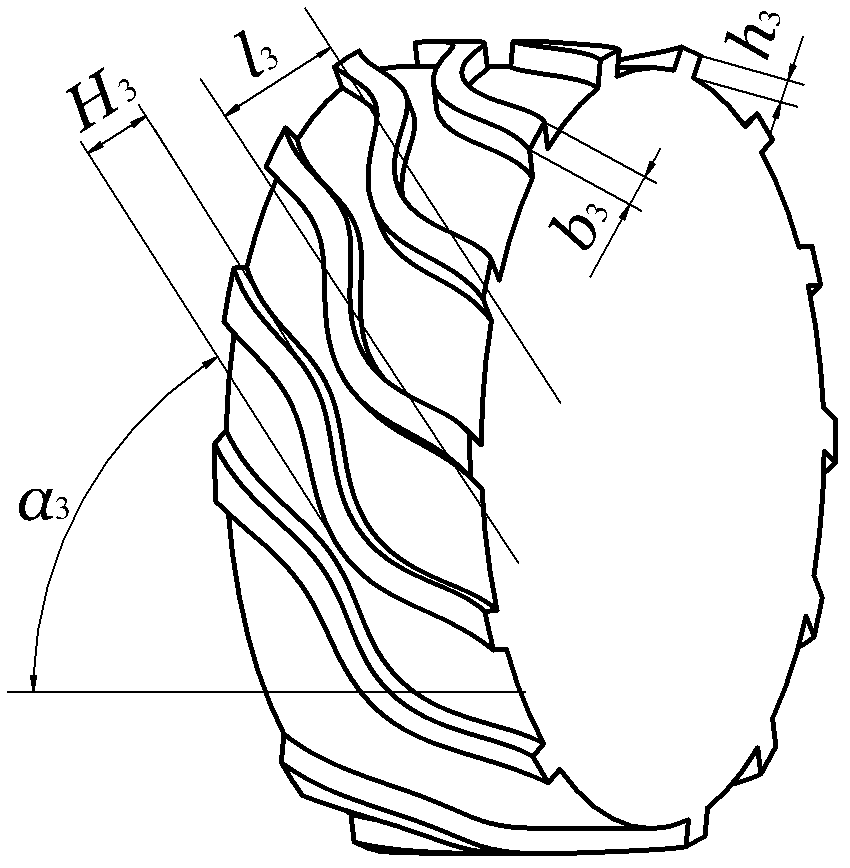

[0052] see image 3 , a cement grinding roller with corrugated bionic coupling wear-resistant surface layer, the core material is 35 medium carbon steel, and the transition layer of the grinding roller is high chromium and high manganese austenite with different components (wt%) according to three different thicknesses Welding materials are surfacing.

[0053] The surface of the grinding roller is processed into three bionic coupling strengthening layers with corrugations in different sizes and distributions by surfacing technology. Its material is high chromium cast iron wear-resistant welding wire with different components (wt%).

[0054] The material composition of the wear-resistant layer is the same as that of the bionic coupling strengthening layer, and is made of welding material surfacing according to three different thicknesses of the wear-resistant layer.

[0055] The parameters of the transition layer, wear-resistant layer and bionic coupling reinforcement layer o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Center distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com