Sulfonated melamine-formaldehyde polycondensate water reducer and preparation method thereof

A technology of sulfonated melamine and formaldehyde polycondensate, which is applied in the field of sulfonated melamine-formaldehyde polycondensate water reducer and its preparation, can solve problems such as failure to achieve ideal molecular weight, small molecular weight of polycondensate, hinder polycondensation, etc., and achieve relief from excessive Influence, reduce the amount of acid and alkali used, improve the effect of thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

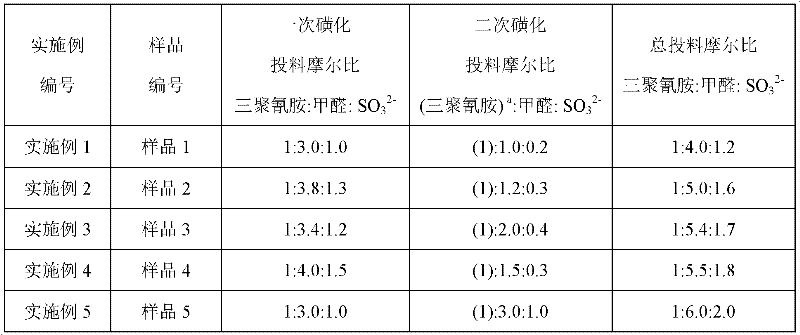

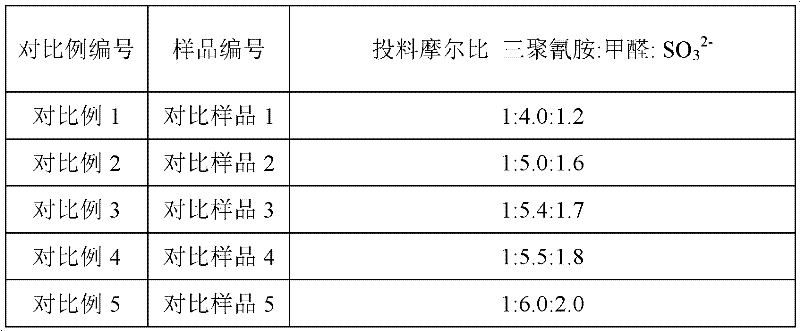

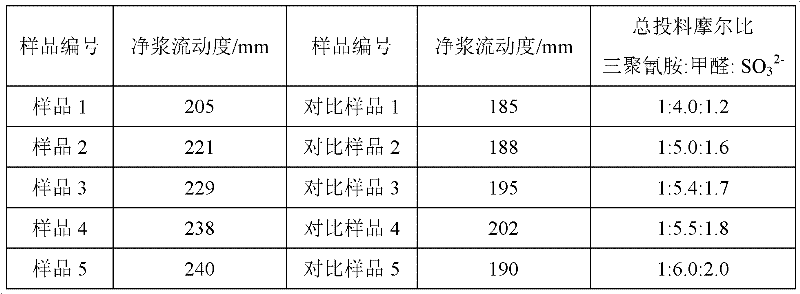

Examples

Embodiment 1

[0037] (1) One sulfonation reaction

[0038] Put 63g (0.50mol) of melamine, 47.5g (0.25mol) of sodium metabisulfite, 10.0g of 30% sodium hydroxide solution and 190g of water into a 500ml flask, start the mechanical stirring, and raise the temperature to 80°C. 121.6 g of 37% formaldehyde solution (containing 1.50 mol of formaldehyde) was added dropwise to the reaction system at a constant speed within 15 minutes, and the pH value was measured to be 11-12 after the addition was completed. The reaction was continued at 80°C for 2 hours.

[0039] (2) Condensation reaction

[0040] 10.0 g of 30% sulfuric acid aqueous solution was added to adjust the pH of the system to 5-6, and the reaction was maintained at 80° C. for 2 hours. The weight-average molecular weight of the polycondensate was determined to be 58,000 by aqueous gel chromatography.

[0041] (3) Secondary sulfonation reaction

[0042] Add 5.0 g of 30% sodium hydroxide solution to adjust the pH value of the system to 8-9....

Embodiment 2

[0044] (1) One sulfonation reaction

[0045] Put 63g (0.50mol) of melamine, 67.6g (0.65mol) of sodium bisulfite, 12.0g of 30% sodium hydroxide solution and 140g of water into a 500ml flask, start the mechanical stirring, and raise the temperature to 90°C. 154.0 g of 37% formaldehyde solution (containing 1.90 mol of formaldehyde) was added dropwise to the reaction system at a constant speed within 40 minutes, and the pH value was measured to be 11-12 after the dropwise addition was completed. The reaction was continued at 90°C for 1 hour.

[0046] (2) Condensation reaction

[0047] 15.0 g of 30% sulfuric acid aqueous solution was added to adjust the pH of the system to 4-5, and the reaction was maintained at 90° C. for 0.5 hours. The weight average molecular weight of the polycondensate was determined to be 48,000 by aqueous gel chromatography.

[0048] (3) Secondary sulfonation reaction

[0049] Add 5.0 g of 30% sodium hydroxide solution to adjust the pH value of the system...

Embodiment 3

[0051] (1) One sulfonation reaction

[0052] Put 63g (0.50mol) of melamine, 75.6g (0.60mol) of sodium sulfite, 2.0g of 30% sodium hydroxide solution and 450g of water into a 1L flask, start the mechanical stirring, and raise the temperature to 70°C. 137.8 g of 37% formaldehyde solution (containing 1.70 mol of formaldehyde) was added dropwise to the reaction system at a constant speed within 60 minutes, and the pH value was measured to be 11-12 after the addition was completed. The reaction was continued at 70°C for 3 hours.

[0053] (2) Condensation reaction

[0054] 15.0 g of 30% sulfuric acid aqueous solution was added to adjust the pH of the system to 4-5, and the reaction was maintained at 70° C. for 2 hours. The weight-average molecular weight of the polycondensate was determined to be 52,000 by aqueous gel chromatography.

[0055] (3) Secondary sulfonation reaction

[0056] Add 11.0 g of 30% sodium hydroxide solution to adjust the pH value of the system to 8-9. Add 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com