Additive ST for regenerated waste gear oil 320

A gear oil and additive technology, applied in the direction of additives, petroleum industry, lubricating composition, etc., can solve the problems of increased friction coefficient and wear, and achieve the effects of restoring tribological characteristics, no environmental pollution, and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

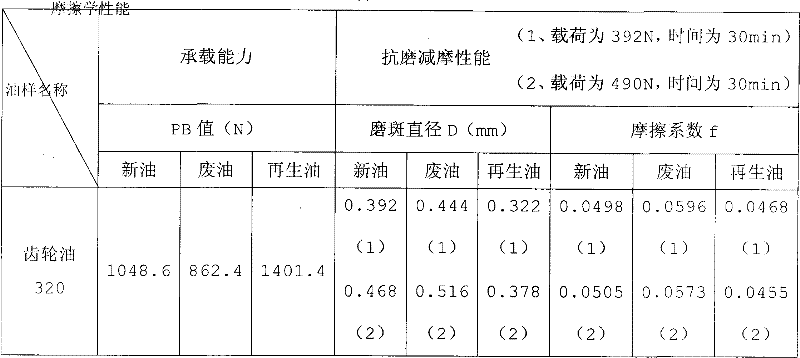

Embodiment 1

[0008] Take 406 oily agent (the unified code is T406-see: China Petrochemical Products Encyclopedia P.454) 20g, epichlorohydrin 40g and 204 anti-oxidant and anti-corrosion agent (the unified code is T204-see: China Petrochemical Products Encyclopedia P. 441) 40g, mixed and reacted at a temperature of 115°C to form the regeneration additive ST, then 3% of the regeneration additive ST was added to 97% of the waste gear oil 320 in which water and slag had been removed by weight percentage, and finally the After stirring for 20 minutes, the waste gear oil 320 can be regenerated, so that the copper corrosion of the waste gear oil 320 is reduced from 1826 grams to 455 grams, and the tribological function is not only restored, but also significantly better than the original new oil: two loads Compared with the original and new oil, the friction coefficient is 6.02% and 9.90% lower, the wear is 17.86% and 19.23% lower than the original and new oil, and the bearing capacity (PB) is 33.6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com