External continuous feeding mechanism for monocrystal furnace

A technology of feeding mechanism and single crystal furnace, applied in the direction of single crystal growth, crystal growth, chemical instruments and methods, etc., can solve problems such as failure to be effectively improved, troubles of production enterprises, etc., to increase the effective use time and improve the utilization rate , the effect of improving the efficiency of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

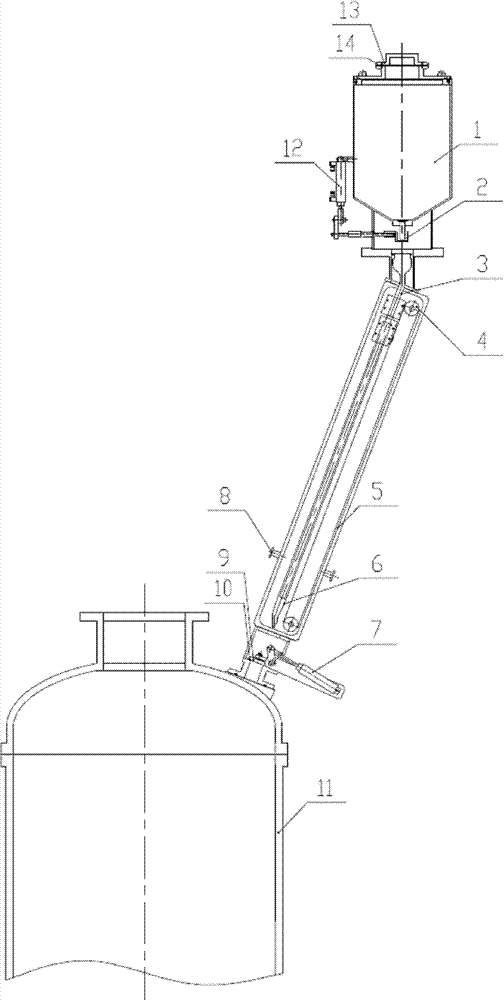

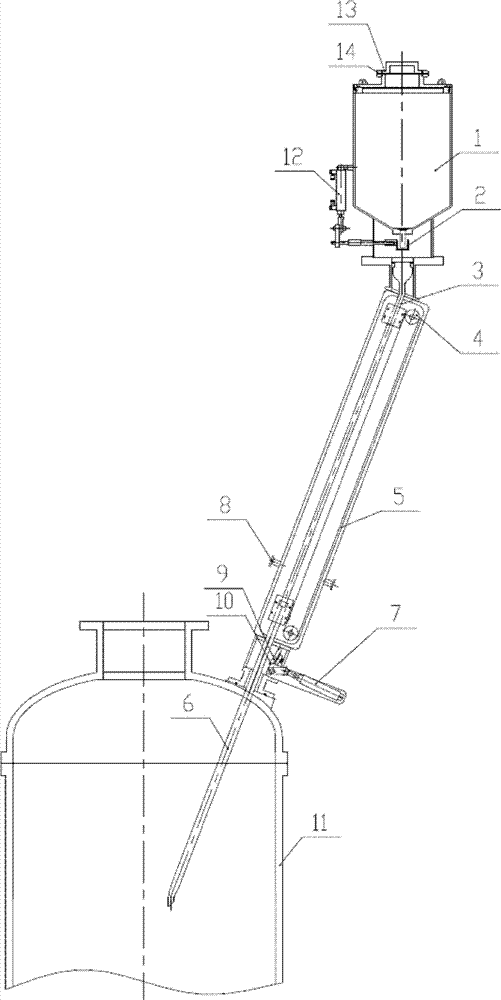

[0019] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0020] The external continuous feeding mechanism used in the single crystal furnace in the present invention includes a feed bin 1 with a sealing cover 13, the middle is sealed and connected with an O-ring 2 14, and a discharge valve 2 is arranged at the bottom; the feed bin 1 is used for loading For polycrystalline silicon materials, the total weight of polycrystalline silicon materials in a single load shall not be less than 30kg.

[0021] The discharge valve 2 controls the discharge amount through a pneumatic device 12, and a discharge outer pipe 6 of quartz material is set outside the discharge inner pipe 3; The telescopic transmission mechanism 4 of the extending direction of the pipe 3 in the discharge is connected. The transmission mechanism 4 includes a control switch, a stepper motor and a transmission cable, which can be realized by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com