Rapid drying method and equipment for ceramic fiberboard

A ceramic fiberboard and rapid drying technology, which is applied in the direction of drying solid materials, drying gas arrangement, lighting and heating equipment, etc., can solve the problems that are not conducive to the control of drying process temperature, large thermal inertia, etc., and achieve the promotion of overall synchronous drying, microwave The effect of uniform power and improved energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

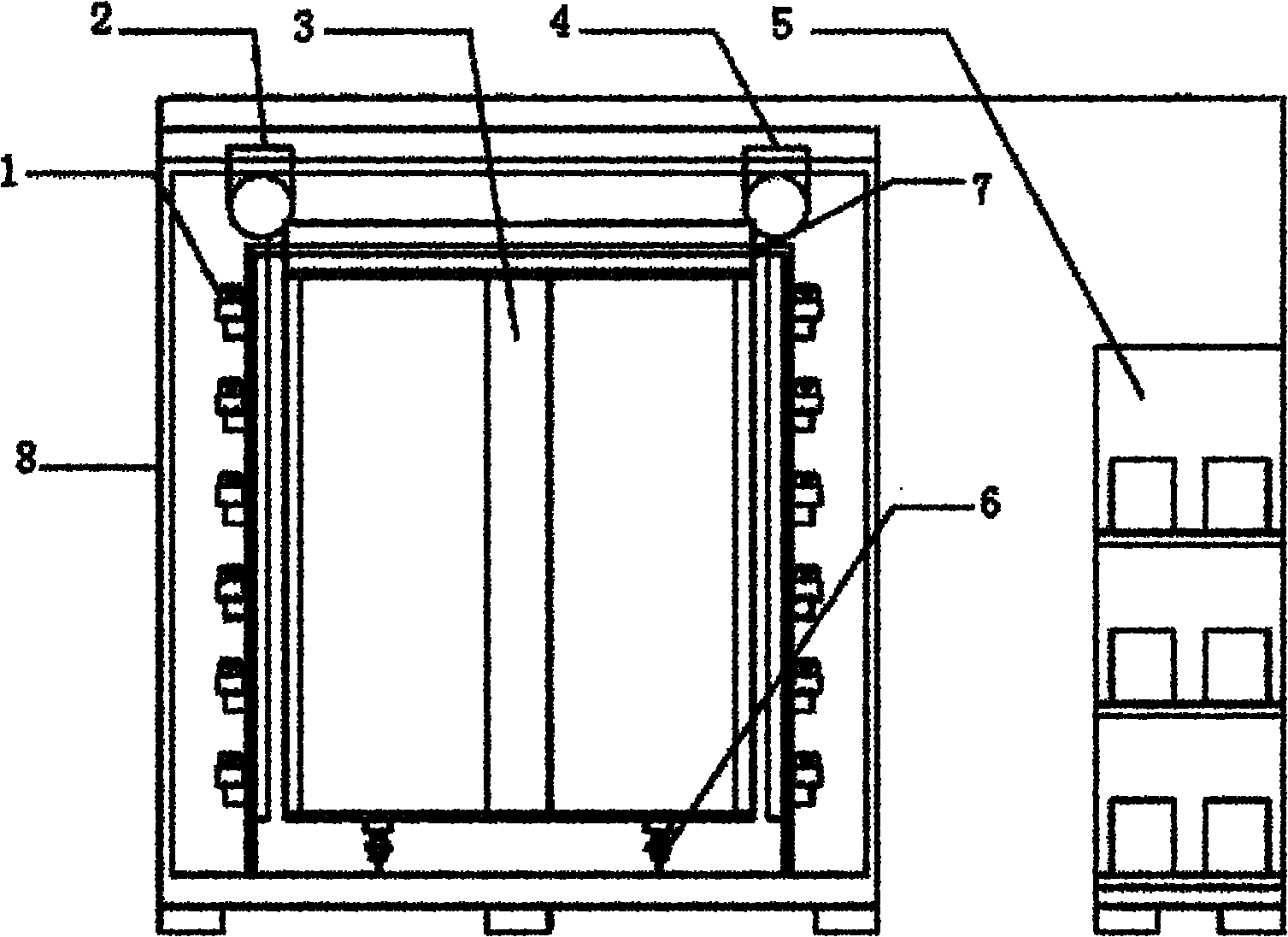

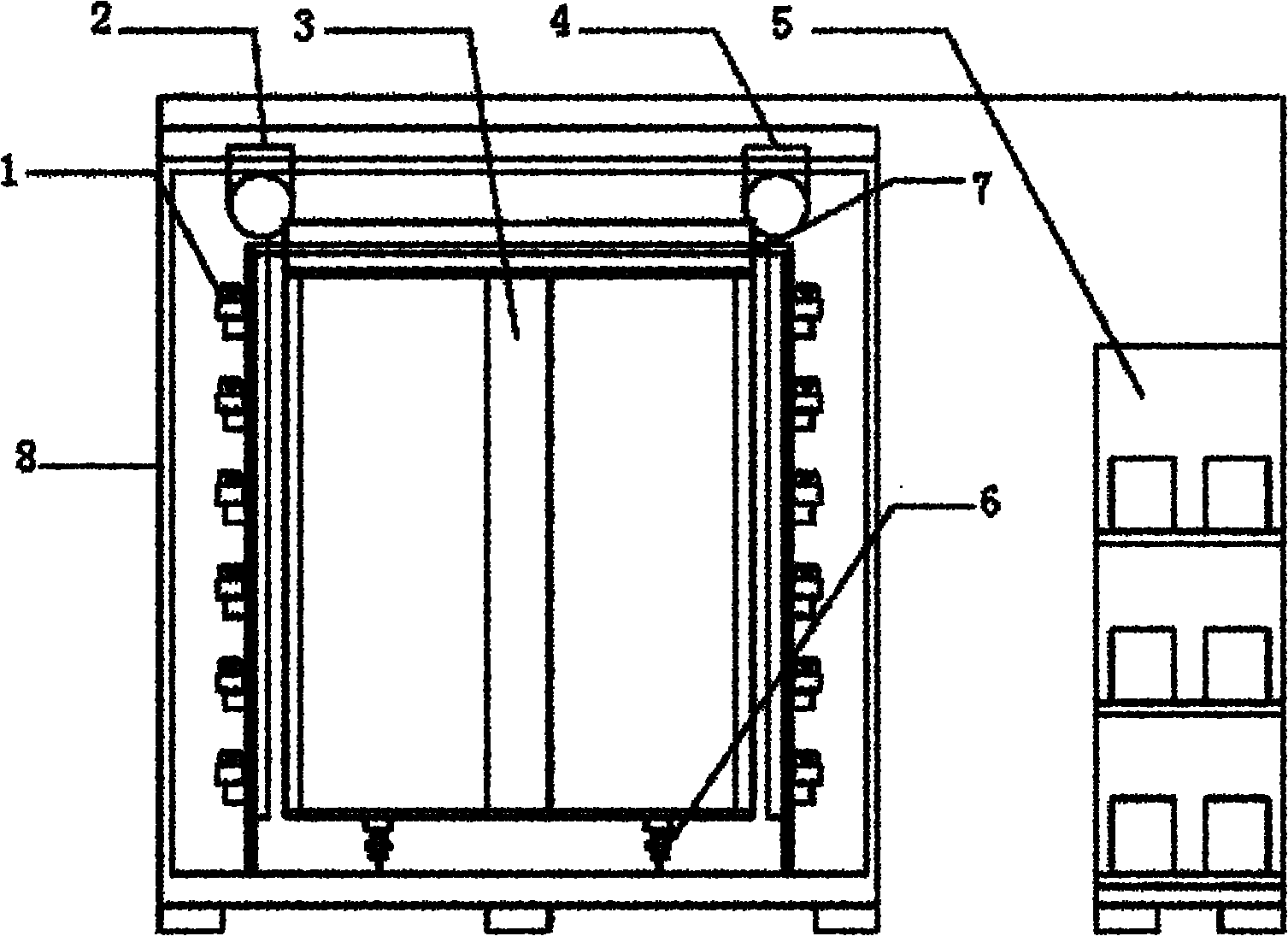

[0031] Example: Place the ceramic fiber boards that need to be dried layer by layer on the backing plate of the trolley, emit microwaves through several microwave generators, penetrate the interior of the ceramic fiber board, and heat from the inside, and the water vapor passes through the internal pores of the ceramic fiber board to At the same time, hot air is introduced into the air inlet, and the evaporated water vapor is discharged through the exhaust duct. The company has built a microwave drying room with a power of 62kw, which can be loaded into a trolley. Considering that each car is conventionally 30 boards with a density of 250kg / m3 and a specification of 1000x600x50, the total weight (including water) is 630kg, and the temperature is adjusted to 80 degrees. The drying can be completed in 8 hours, which is 6 times more efficient than the previous ordinary drying room in 48 hours.

[0032] like figure 1 The shown ceramic fiber board rapid drying equipment inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com