Single-mode optical fiber and optical system

A single-mode fiber, fiber core technology, applied in optics, transmission systems, cladding fibers, etc., can solve the problem of increasing manufacturing costs, failing to provide satisfactory distribution characteristics and/or propagation characteristics, and increasing fiber manufacturing costs. Macrobending loss and other problems, to achieve the effect of low bending loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

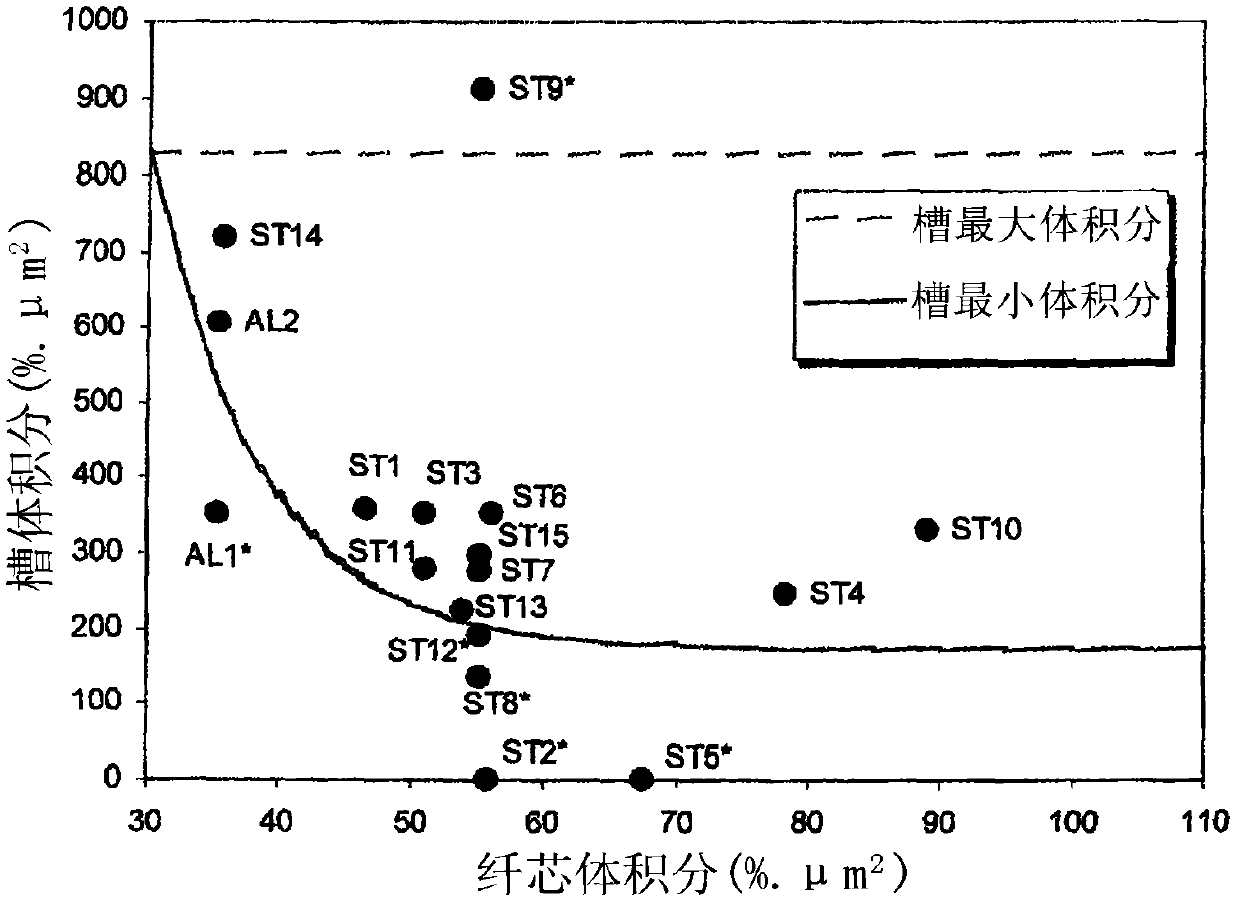

[0077] The present invention proposes to increase the effective area Aeff of the single-mode optical fiber to more than 150 μm by relaxing the constraints on the cut-off wavelength λcc in the optical cable, that is, by allowing λcc to exceed 1450 nm 2 .

[0078] To this end, the invention proposes the use of fiber distributions with buried cladding.

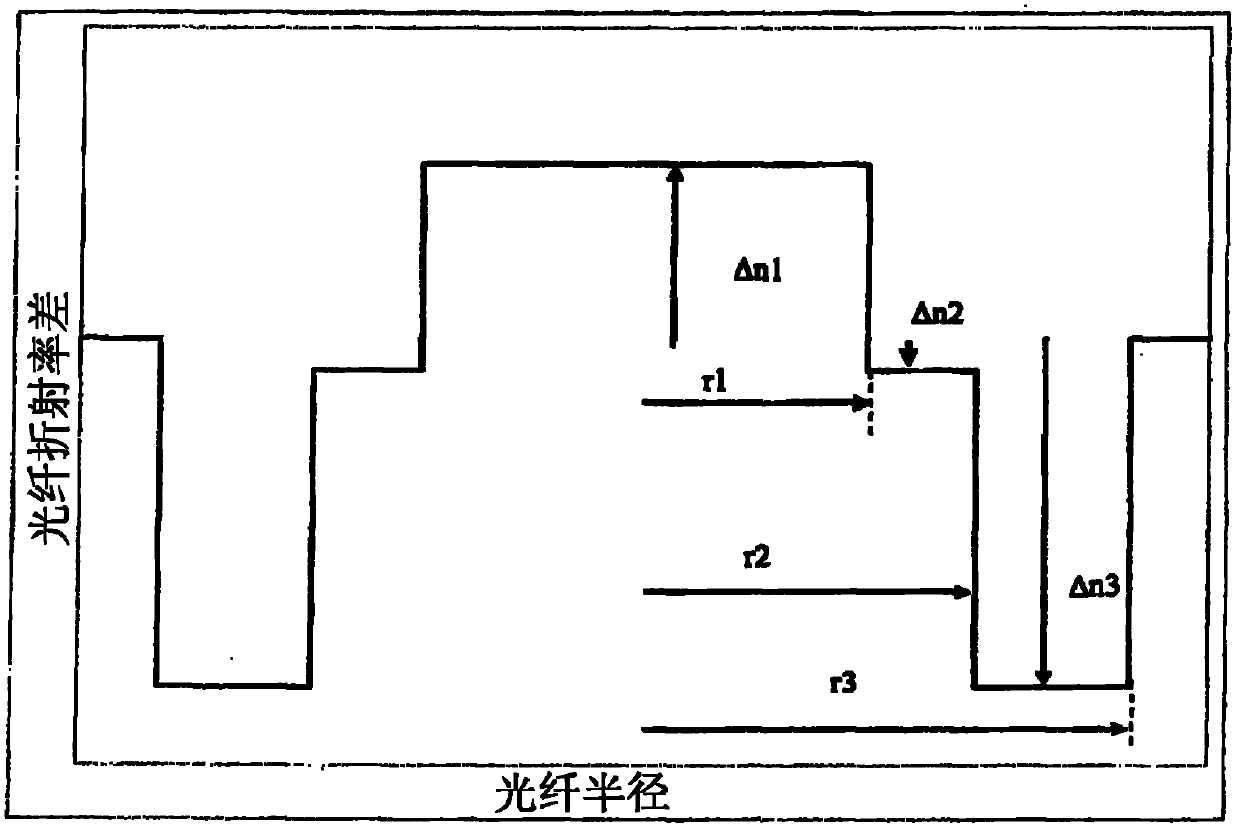

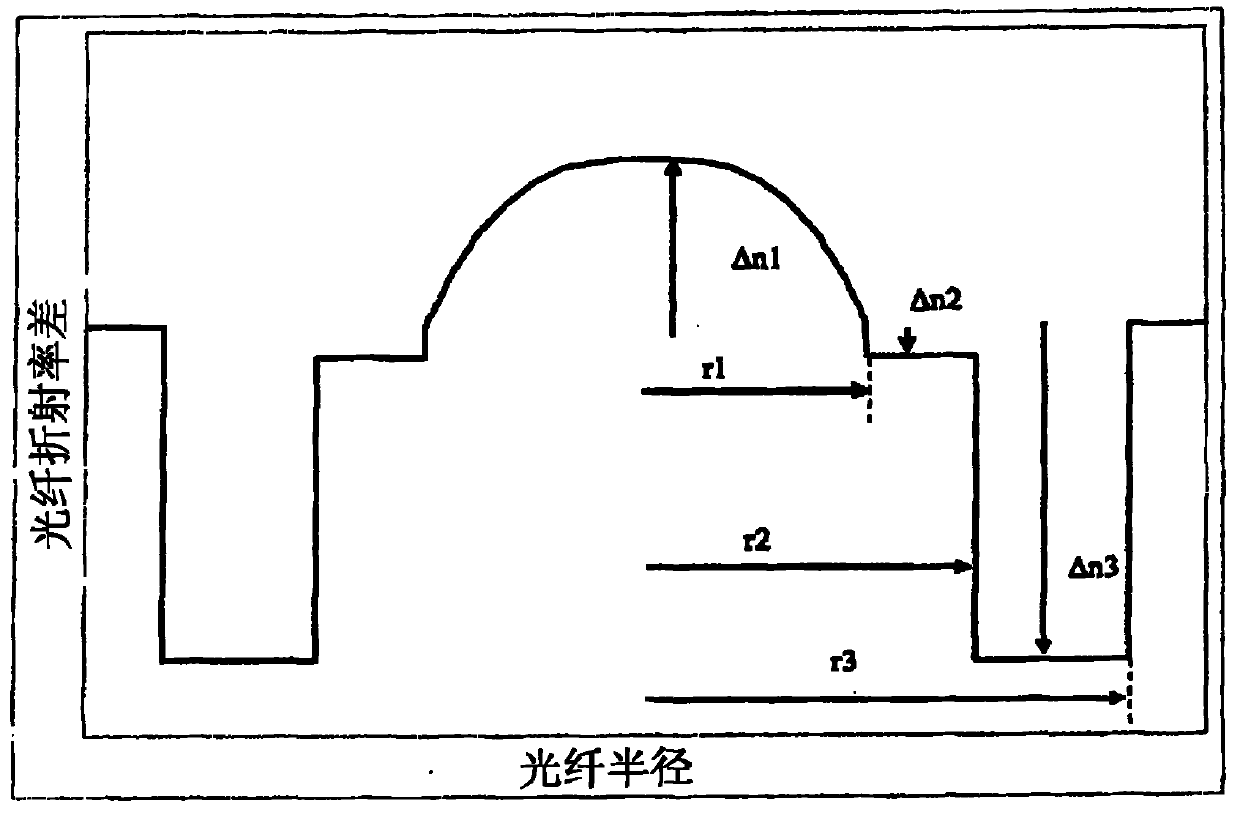

[0079] Thus, the optical fiber of the present invention has a central core, an intermediate cladding, and a buried cladding or trench. The central core, intermediate cladding and buried cladding are typically produced by chemical vapor deposition (CVD) inside a silica tube. The outer optical cladding consists of a silica tube and the outer cladding of the silica tube, usually made of natural or doped silica, but any other deposition technique (vapor axial deposition (VAD) , vapor axial deposition) or external vapor deposition (OVD, outside vapor deposition)) to produce the outer optical cladding.

[0080] For example, Plasma C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Area | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com