Substrate conveying device and substrate conveying method for coating purpose

A transmission device and substrate technology, which is applied in the directions of transportation and packaging, conveyor objects, electrical components, etc., can solve the problems of large loading and unloading workload, unstable temperature and high production cost of substrates and metal fixing parts, and achieves a simple substrate transmission method. Practical, high utilization rate of source material, low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

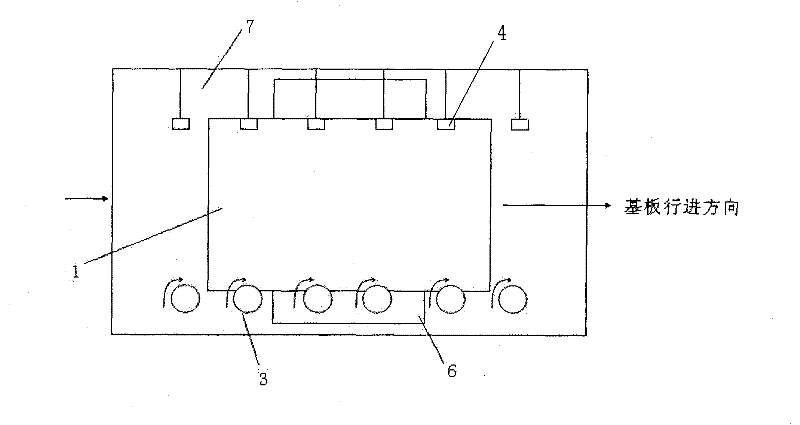

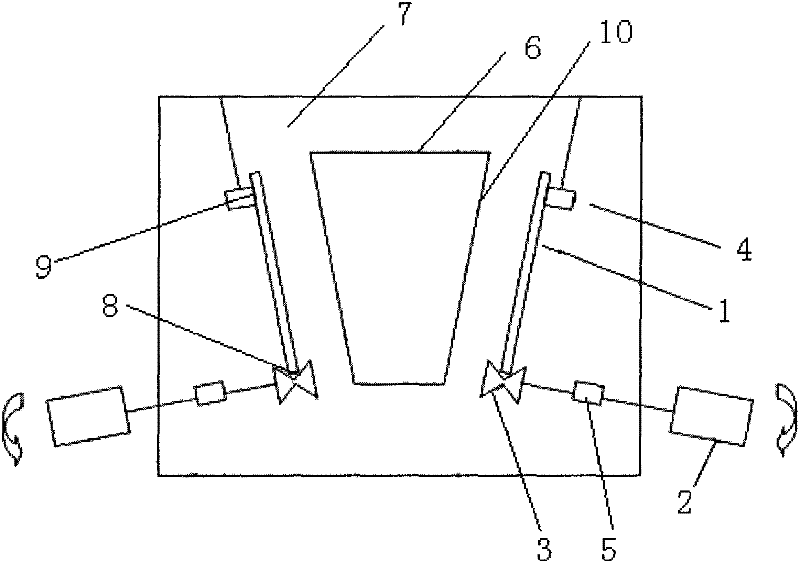

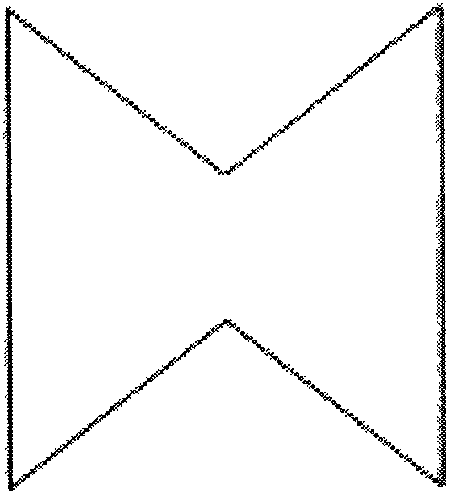

[0041] Such as figure 1 with figure 2 As shown, the substrate transmission mechanism in the substrate transmission device includes a motor 2 and a plurality of transmission wheels 3 driven by the motor 2, and the transmission wheels 3 are driven by a chain, and the cross-sectional shape of the transmission wheels 3 is triangular (see Figure 3A ), the motor 2 and the transmission wheel 3 are used to realize the stable transmission of the substrate 1. The substrate supporting mechanism 4 is a fixed guide wheel, and the working surface 9 of the substrate supporting mechanism is the bottom of the substrate 1 . If the substrate 1 is located in a high-temperature environment, the materials of the transmission wheel 3 and the substrate supporting mechanism 4 must be resistant to high temperature. The material of the transmission wheel 3 and the substrate supporting mechanism 4 is silicon carbide. In order to more effectively prevent the substrate 1 from falling over, the guide w...

Embodiment 2

[0044] The structure of the substrate conveying device used for coating is the same as that of Embodiment 1, the difference is that there are multiple motors 2, and each motor 2 is connected to a transmission wheel 3, and an elastic coupling 5 is connected between the transmission wheel 3 and the motor 2, and the substrate The conveying of 1 has shock-absorbing and cushioning effect; The substrate support mechanism 4 is a movable pulley, and the height from the bottom of the substrate 1 is four-fifths of the height of the substrate 1; the cross-sectional shape of the transmission wheel 3 is rectangular (see Figure 3B ), the spacing between the drive wheels 3 is the 1 / 4 width of the substrate in the horizontal direction; the material of the drive wheels 3 and the substrate support mechanism 4 is silicon nitride; in order to improve the uniformity of the edge coating, the effective coating of the coating source 6 The height is slightly greater than the height of the substrate 1....

Embodiment 3

[0048] The structure of the substrate conveying device used for coating is the same as in Embodiment 2, except that the material of the transmission wheel 3 and the substrate support mechanism 4 is quartz, and the cross-sectional shape of the transmission wheel 3 is arc-shaped (see Figure 3C ), the substrate support mechanism 4 is a slider that can move with the substrate 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com