Liquid crystal display device

A liquid crystal display device, liquid crystal technology, applied in instruments, nonlinear optics, optics, etc., can solve the problems of rising cost and inferior viewing angle characteristics, and achieve low gray level characteristics, good wide viewing angle characteristics, and good high-speed response. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

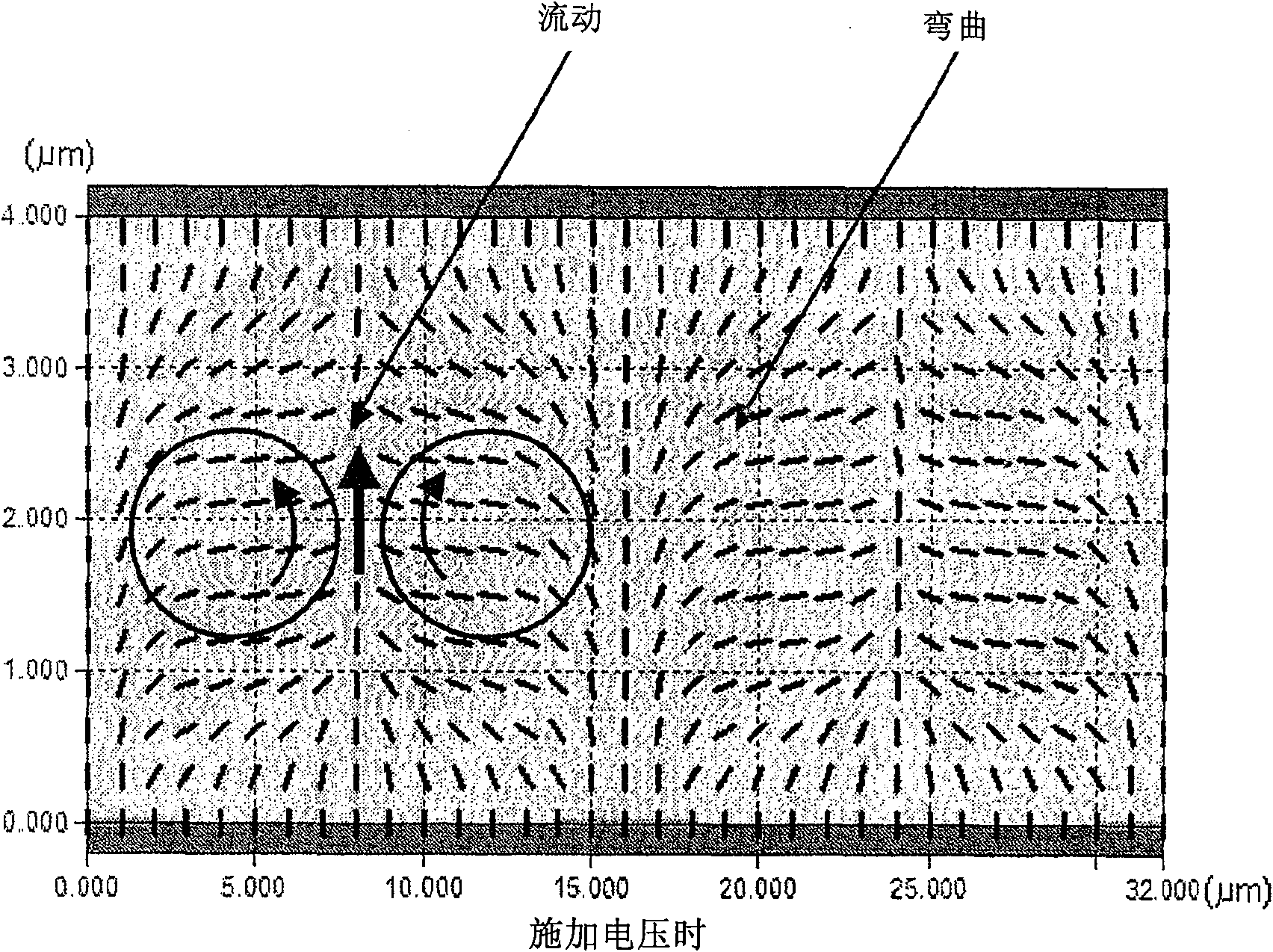

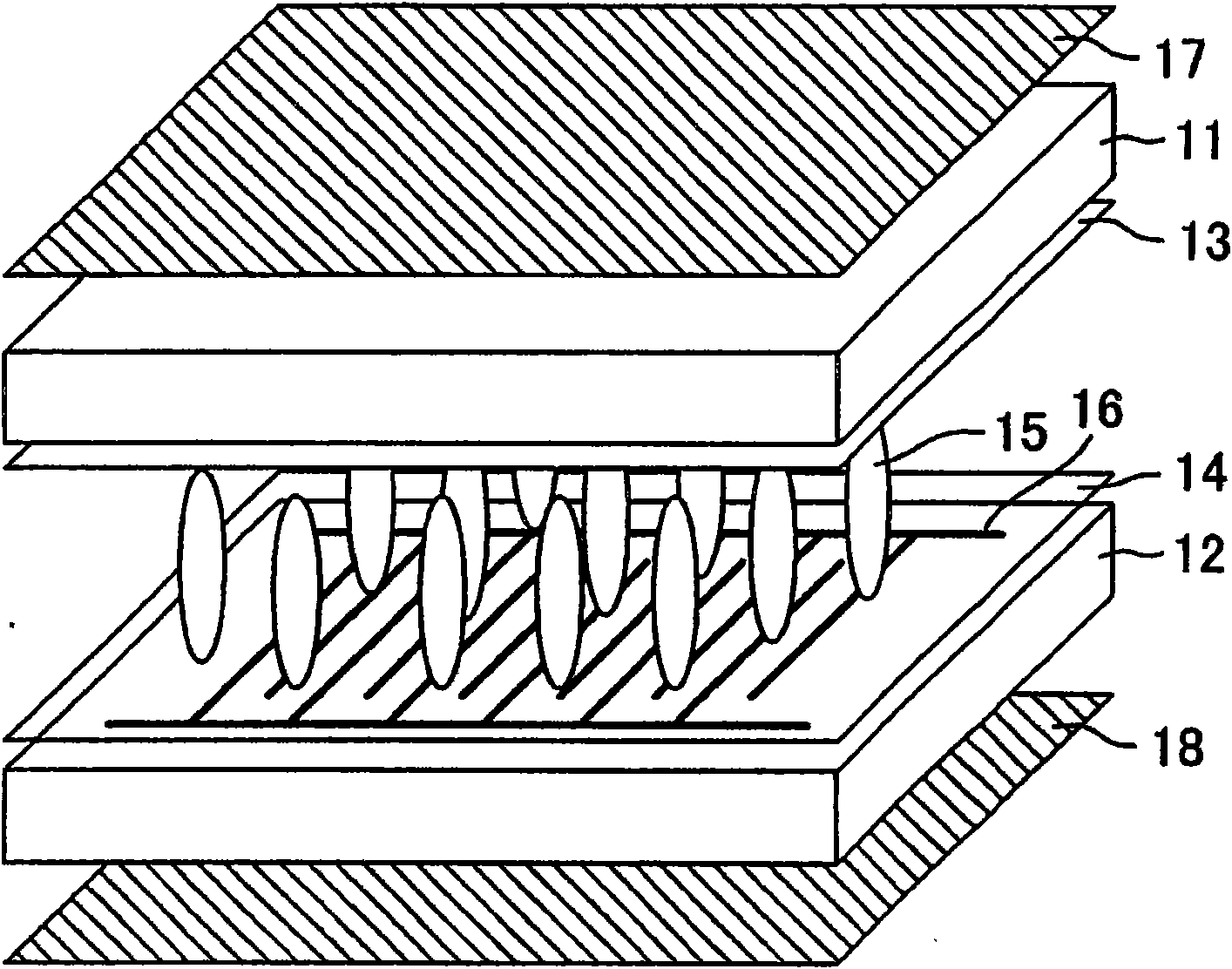

[0091] The liquid crystal display device of the present embodiment is a liquid crystal display device in which an electric field intensity distribution is formed in a cell by applying an electric field, thereby realizing bend alignment of liquid crystals. In addition, the liquid crystal display device of this embodiment is a liquid crystal display device in which an electric field is applied to p-type nematic liquid crystals (nematic liquid crystals having positive dielectric anisotropy) aligned vertically in the lateral direction with respect to the substrate surface, and is characterized in that In that a more curved arrangement is formed by applying an electric field. figure 1 It is a schematic perspective view showing the basic configuration of the liquid crystal display device of the first embodiment. Vertical alignment films 13, 14 are arranged on the two transparent substrates 11, 12, and p-type nematic liquid crystals (liquid crystal molecules 15) exhibit vertical ali...

Embodiment 1

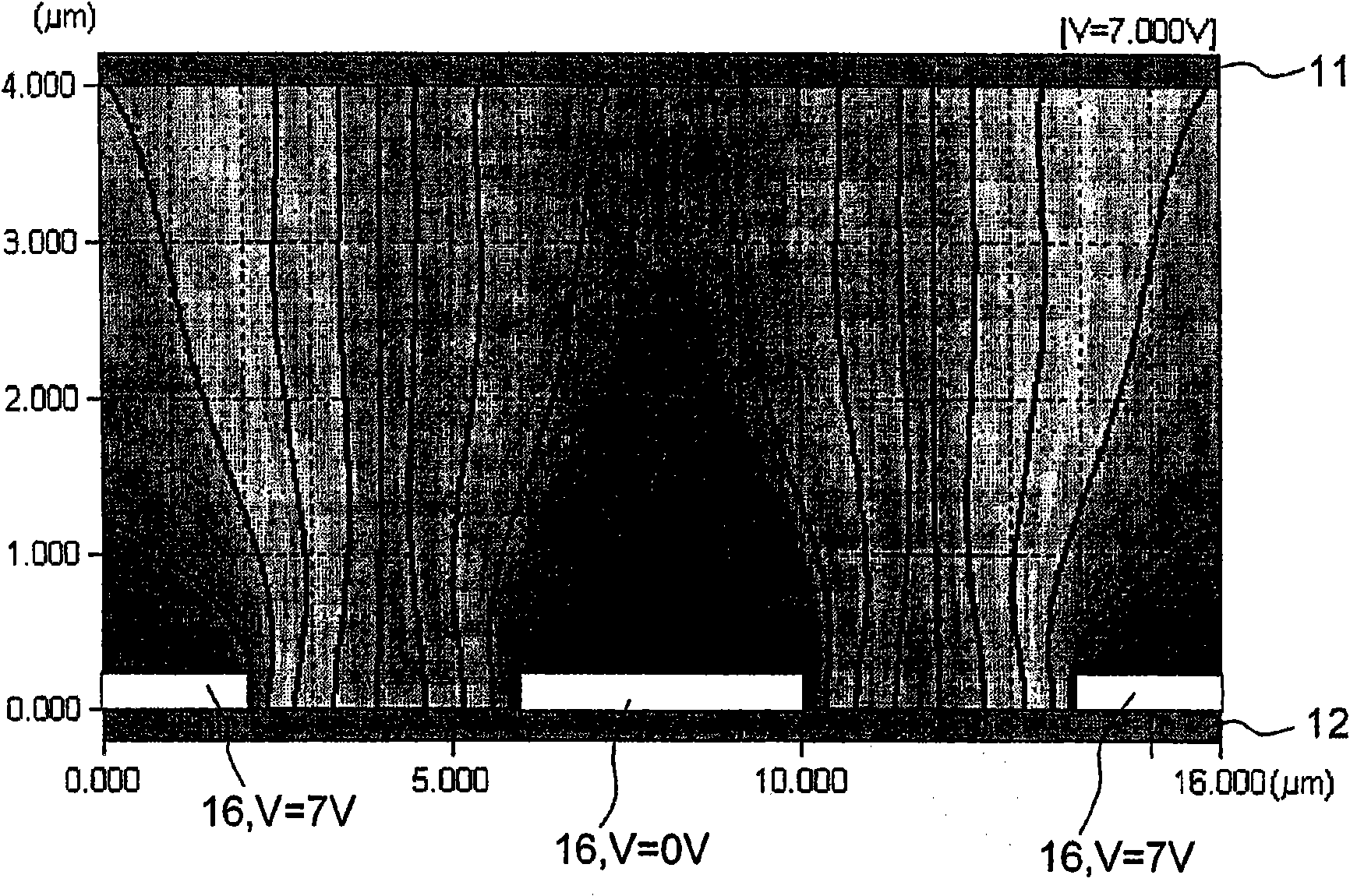

[0103] A schematic cross-sectional view showing the basic structure of the liquid crystal display element of Example 1 is at Figure 4 Indicated. A plurality of liquid crystal display elements having various electrode widths L and electrode intervals S were produced. First, the alignment film JALS- 204 (5 wt.%, γ-butyrolactone solution), and fired at 200° C. for two hours to form an alignment film 44 . The film thickness of the alignment film 44 at this time was 60 nm. Similarly, an alignment film 45 having a film thickness of 60 nm was formed on the glass substrate 43 using the same alignment film paint as that of the alignment film 44 . Thereafter, resin beads 46 (Micropearl SP: microbead SP) manufactured by Sekisui Chemical Co., Ltd. with a diameter of 4 μm were dispersed on the substrate 42, and sealing resin 47 (Stract bond) manufactured by Mitsui Topress Chemical Co., Ltd. was printed on the substrate 43. XN-21-S: Structural body adhesive XN-21-S), these board|substr...

Embodiment 2

[0124] The basic structure and Figure 4 Similarly, a liquid crystal cell in which the electrode width L is 4 μm, the electrode spacing S is 4 μm, and the cell gap is 4 μm.

[0125] First, a glass substrate 42 having a comb-shaped electrode (comb-teeth electrode) 41 made of ITO is dipped in the chemical formula CF 3 -(CF 2 ) 17 -SiCl 3 After 5 minutes in the 0.01mol / l chloroform-NMP mixed solution (chloroform: NMP mixing ratio (volume ratio) = 1:10) of the indicated silane coupling agent, dry it at 120°C in dry nitrogen. After drying for 1 hour, an alignment film 44 (interfacial anchor energy: 5×10 -5 J / m 2 ).

[0126] Similarly, an alignment film 45 was formed on the glass substrate 43 using the same alignment film material as that of the alignment film 44 . Thereafter, resin beads 46 (Micropearl SP) with a diameter of 4 μm produced by Sekisui Chemical Co., Ltd. were dispersed on the substrate 42, and sealing resin 47 (Structure Adhesive XN -21-S) These substrates wer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com