Light-emitting diode (LED) ultraviolet fluid disinfection method and device thereof

A technology of disinfection device and disinfection method, applied in the fields of food science, food preservation, light water/sewage treatment, etc., can solve the problems of affecting the life of electrodes, difficult to realize power adjustment control, etc. Excellent performance and high safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

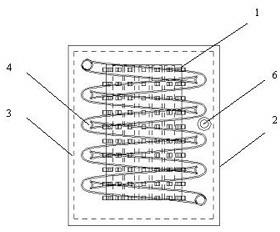

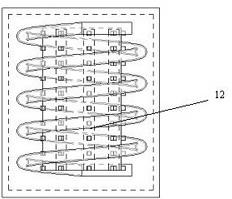

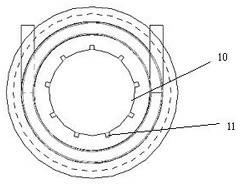

[0027] Embodiment 1: with reference to attached figure 1 to attach image 3 As shown, the LED ultraviolet fluid disinfection device described in this embodiment is mainly composed of a circular protective shell 2, an LED ultraviolet disinfection assembly 1 and a spiral sleeve 4 of a fluid passage. Wherein, the inner wall of the protective shell 2 is provided with an ultraviolet reflective layer 3, and the LED ultraviolet disinfection assembly 1 is inserted into the middle of the spiral sleeve 4 for disinfection. The LED disinfection assembly 1 is composed of a circular support 10 made of flexible printed circuit and an ultraviolet LED module 12 equipped with an integrated high power density ultraviolet LED light source 11 . The shape of the outer edge of the support member 10 is circular, which can ensure that the ultraviolet LED module 12 can uniformly and efficiently disinfect the fluids to be disinfected in all directions, such as water, etc., and the inner wall of the cir...

Embodiment 2

[0030] Embodiment 2: with reference to attached Figure 4 to attach Image 6 As shown, the difference from Embodiment 1 is that the support member 10 of this embodiment adopts a rigid printed circuit structure and its outer edge shape is hexagonal.

[0031] as attached Figure 4 And attached Figure 7As shown, this disinfection device can also be equipped with an ultraviolet radiation intensity detection probe 6, and the change of the ultraviolet radiation intensity of the disinfection device ultraviolet radiation intensity detection probe 6 detected by the control circuit (the change of the ultraviolet radiation intensity may be caused by the change of the water supply pressure) Changes in the flow rate may also be caused by changes in the water quality of the water supply) to intelligently control the number of LED modules 12 turned on to achieve its intelligent control, so as to reduce the number of LEDs used as much as possible under the condition of sufficient disinfect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com