Pressurized locking combined screw system and special composite screwdriver

A screw and thread technology, applied in the field of internal fixation devices and systems, can solve the problems of internal fixation failure, accumulation of experience depending on failure, fractured cancellous bone and thread interface, etc., to reduce the possibility of bone thread wear, good Angular axial stability, favorable for sustained effect of compressive stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Taking joint fracture as an example below, the present invention will be further described in detail in conjunction with the accompanying drawings.

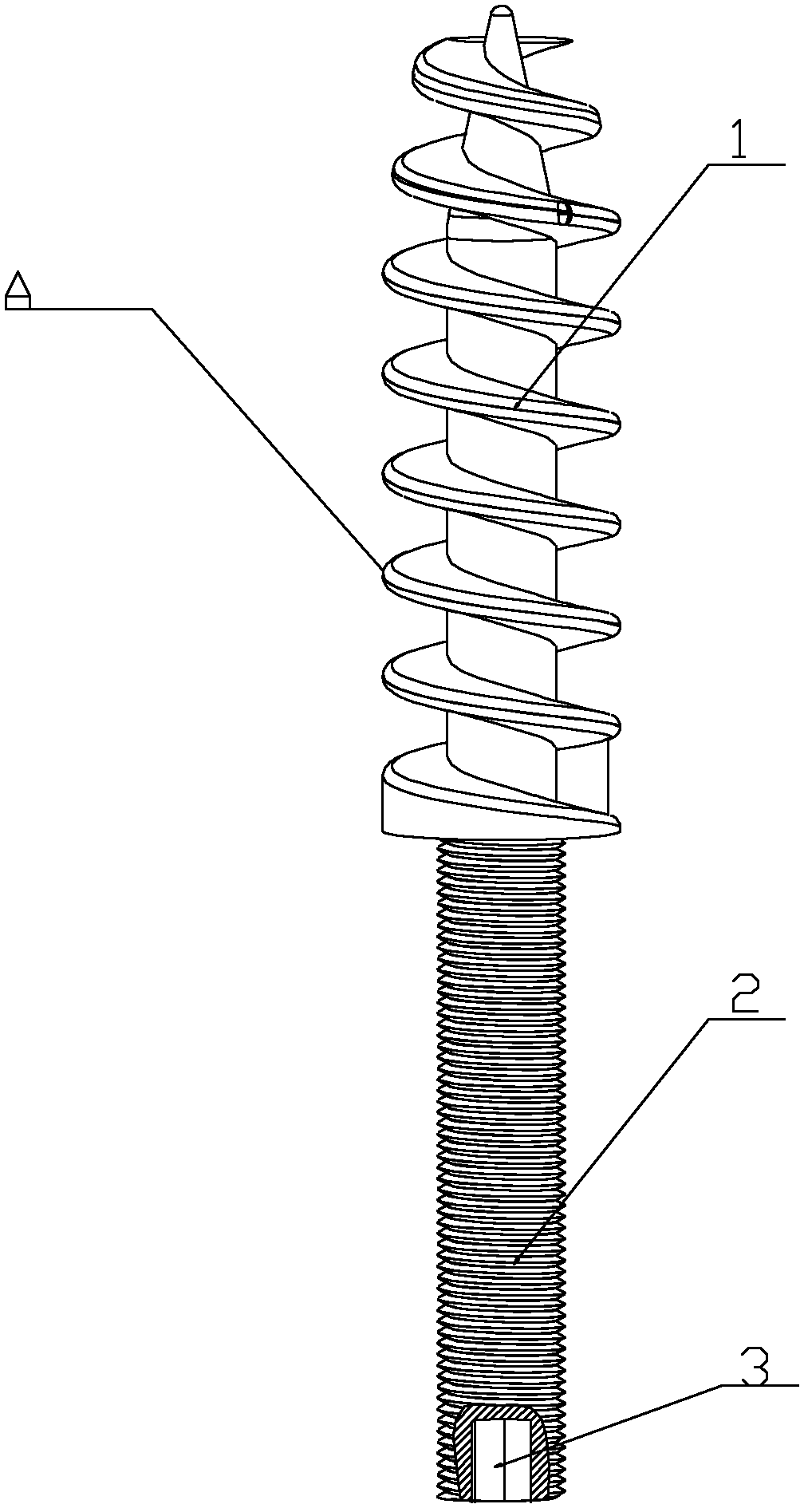

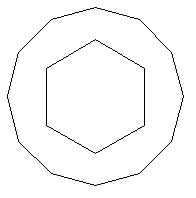

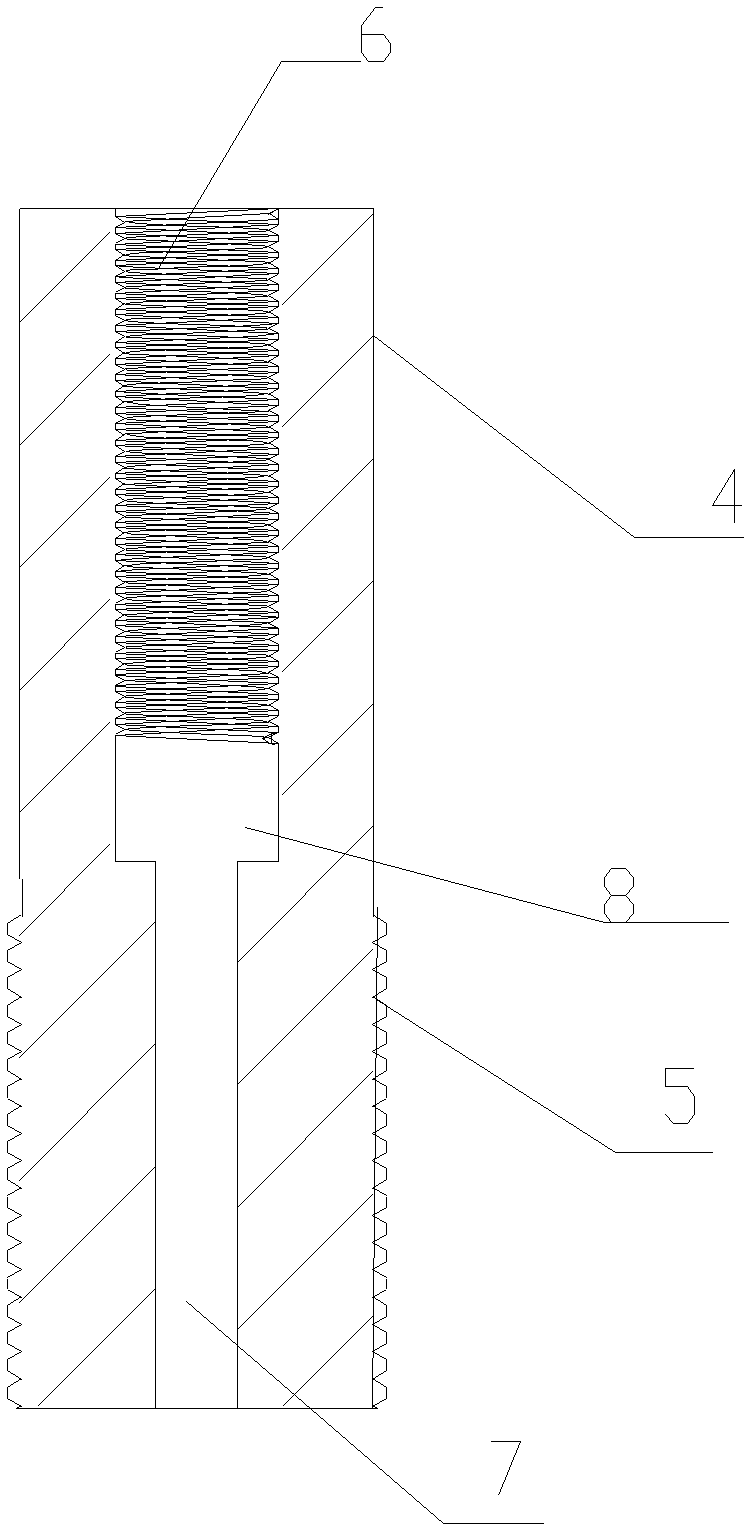

[0045] like Figure 1-Figure 12 , The compression locking combination screw system of the present invention consists of the following components: component A, type I component B, type II component B and locking bone plate C. Figure 10 , Figure 11 It is a schematic diagram of a compound screwdriver. It includes: first thread 1, second thread 2, prismatic structure 3, third thread 4, fourth thread 5, third thread 4 internal hollow 6, fourth thread 5 internal hollow 7, excessive threadless part 8, The sixth thread 9, the inner screwdriver 10, the outer screwdriver 11, the fifth thread 12.

[0046] like figure 1 , 2 As shown, component A is composed of a first thread 1 and a second thread 2. The tail of the second thread 2 is provided with a prismatic structure, which can be a prismatic rod or a hollow prismatic hole, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com