Method for forming precision forging billet of output spline shaft of automobile automatic transmission

A technology of automatic transmission and forming method, applied in metal processing equipment and other directions, can solve the problems of high comprehensive cost, low material utilization, and difficult processing, and achieve high production scheduling and production organization efficiency, high material utilization, and forming accuracy. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

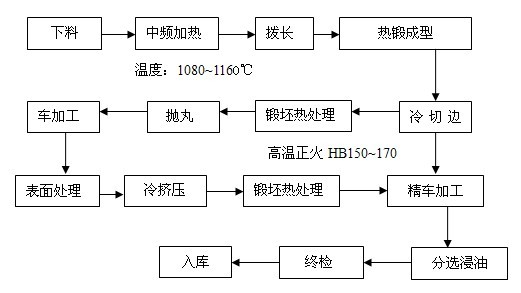

[0029] like figure 1 Among them, the automobile automatic transmission output spline shaft precision forging blank forming method of the present invention is characterized in that comprising the following steps:

[0030] (1) Prepare the raw materials according to the process design requirements, grind the surface of the raw materials, check the cracks, and then saw them into material sections, and remove the material sections that do not meet the requirements; generally use ∮45mm diameter bar;

[0031] (2) Heat the material section to 1080-1160°C; specifically, 1090°C, 1100°C, 1110°C,

[0032] 1120°C, 1130°C, 1140°C, 1150°C, etc.

[0033] (3) Elongate the material section on the press to increase the length-to-diameter ratio of the blank, and obtain a blank whose length-to-diameter ratio meets the process requirements; use an air hammer to elongate the specific press, and use a forming mold to constrain the outer diameter. Effectively solve the defect of easy folding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com