Electric leveling support system

A support system and electric technology, applied in the direction of supporting machines, transmission devices, machine platforms/supports, etc., can solve problems such as large hydraulic oil tanks, time-consuming, laborious, and environmental pollution, and achieve high reliability, high efficiency, and environmental friendliness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

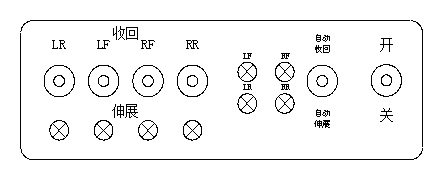

[0023] The invention relates to an electric leveling support system, comprising: four electric leveling legs; according to the principle of determining a plane by three points, to adjust a certain plane to level, as long as any two intersecting straight lines on the adjustment plane reach level . The present invention relies on the height adjustment of four electric leveling legs to reach the platform level. Place a dual-axis inclination sensor at the center of the platform to measure the horizontal inclination of the platform in the X and Y directions. When both inclinations are zero, the platform is completely horizontal.

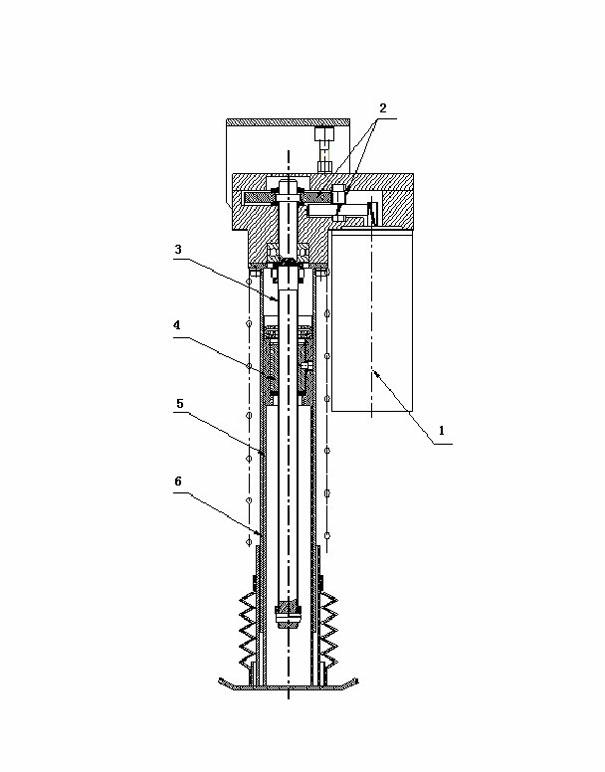

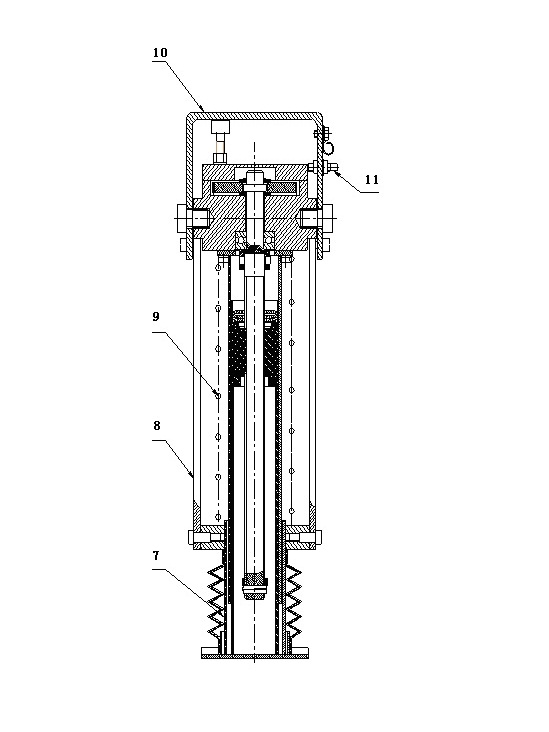

[0024] Each leveling leg is mainly composed of motor 1, gear reduction mechanism 2, screw rod 3, nut 4, inner casing 5, outer casing 6, sleeve slider 7, connecting rod 8, spring 9, support frame 10 and Hall Switch 11 etc. are made up.

[0025] When working, operate the control interface switch, the relay box drives the motor 1 to rotate, the motor 1 dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com