Production line for bagging elastic strips

A production line and elastic strip technology, applied in the field of mechanical systems, can solve the problems of waste of resources, troubled development, and large consumption of anti-rust oil, and achieve the effects of reducing labor intensity, improving working environment, and reducing the amount of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

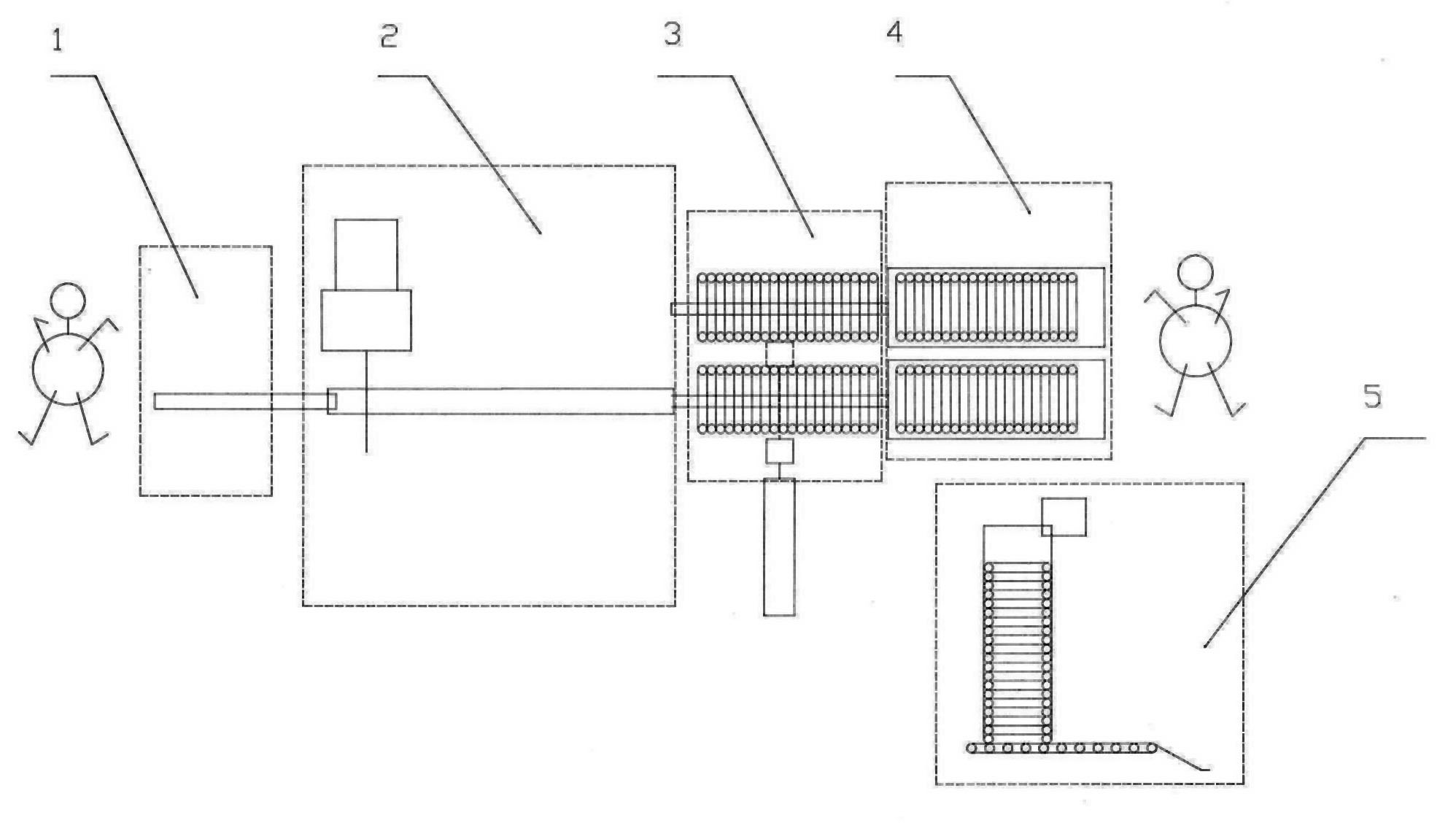

[0017] An elastic bagging production line includes a feeding area 1, a conveying area 2, a counting and distributing area 3, a bagging area 4, and a sealing area 5. Manual loading starts from loading area 1, and then the elastic bar slides into the conveying area 2 by gravity. After the anti-rust oil is sprayed in the conveying area, the elastic bar enters the counting and distributing area 3, and the counting rack is in the two stations. Switch between positions to complete the counting of the elastic strips, and then be pushed into the bagging area 4 by the cylinder, and the bagging is manually assisted, and the final sealing is completed in the sealing area 5.

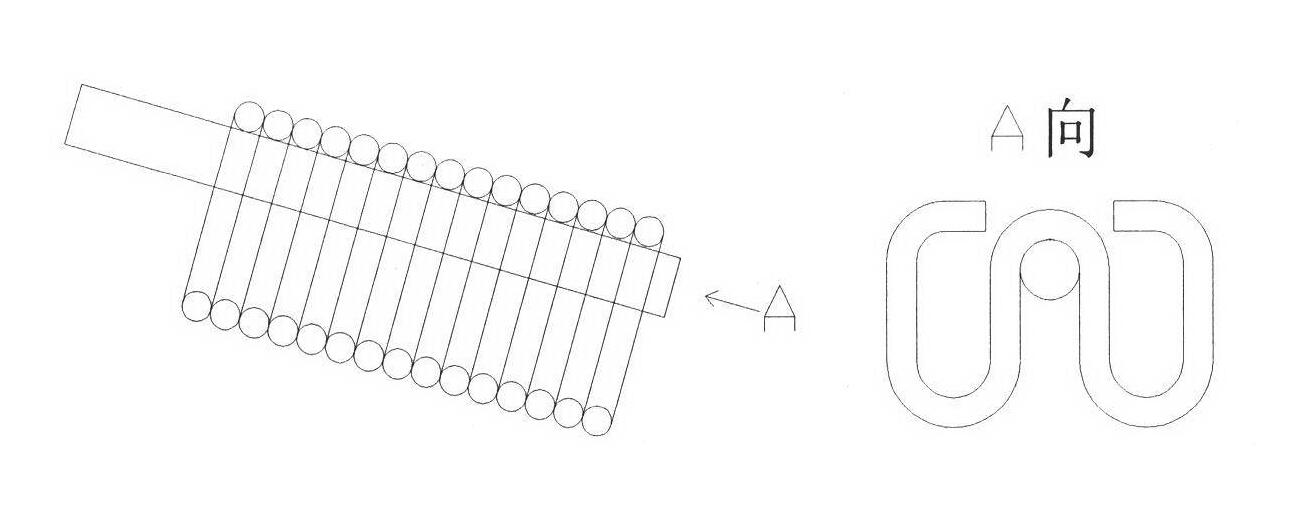

[0018] The feeding area is mainly composed of a round bar at an angle to the ground.

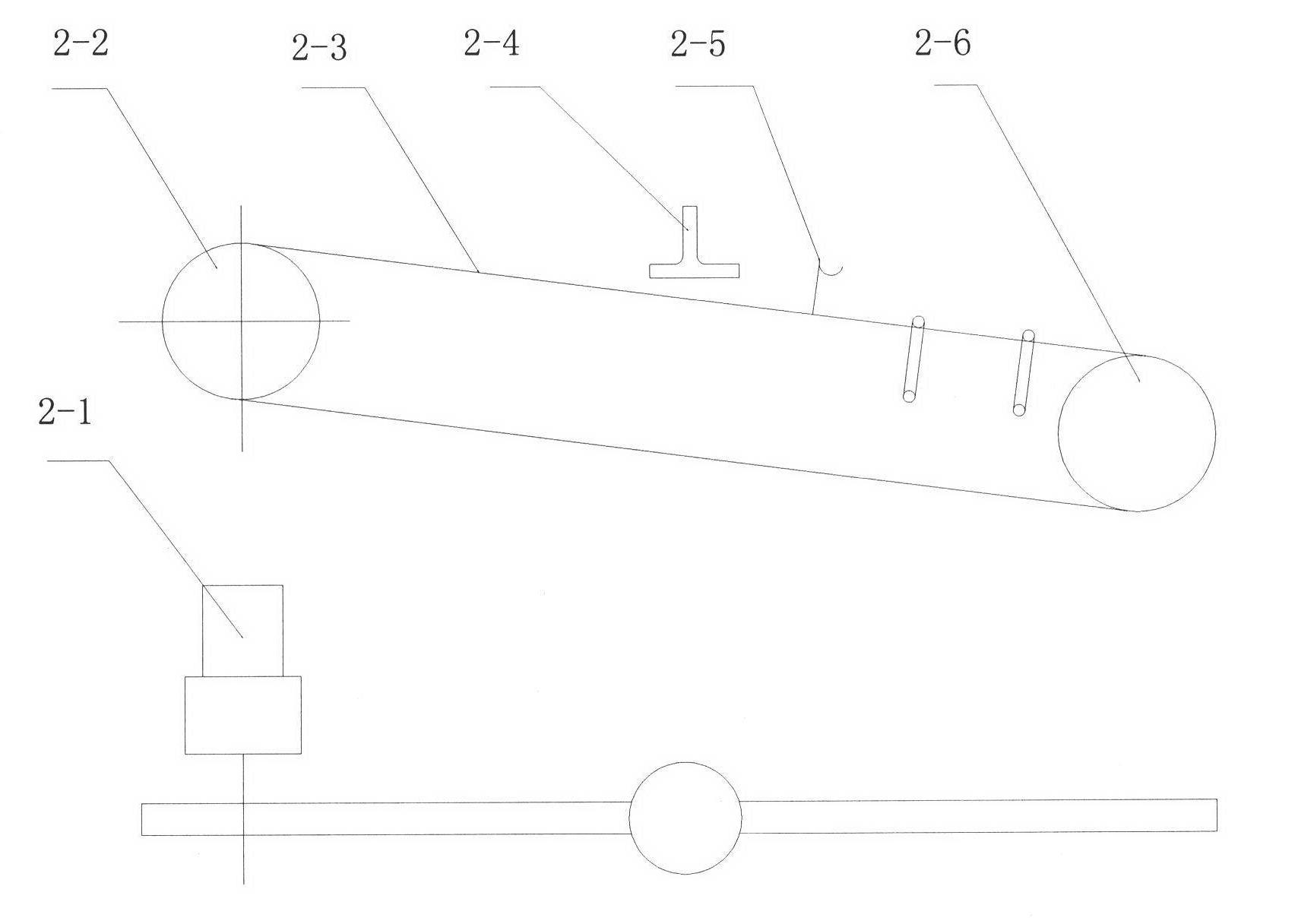

[0019] The transmission area is mainly composed of a geared motor 2-1, a sprocket 2-2, a chain 2-3, a nozzle 2-4, an elastic support frame 2-5 and a sprocket 2-6. The reduction motor 2-1 is driven to rotate on the side of the spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com