Production process of winebottles with decorations

A production process and technology of wine bottles, applied in the field of B65D, can solve the problems of bottle bursting, unreasonable heating process, waste of time, etc., and achieve the effect of preventing black spots, stabilizing the atmosphere in the furnace, and improving the baking quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

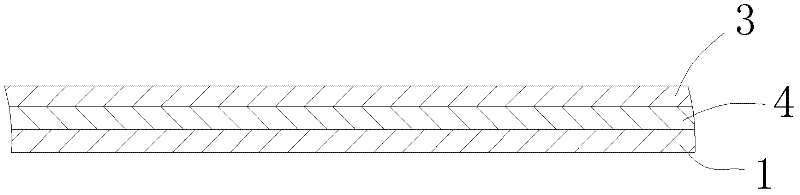

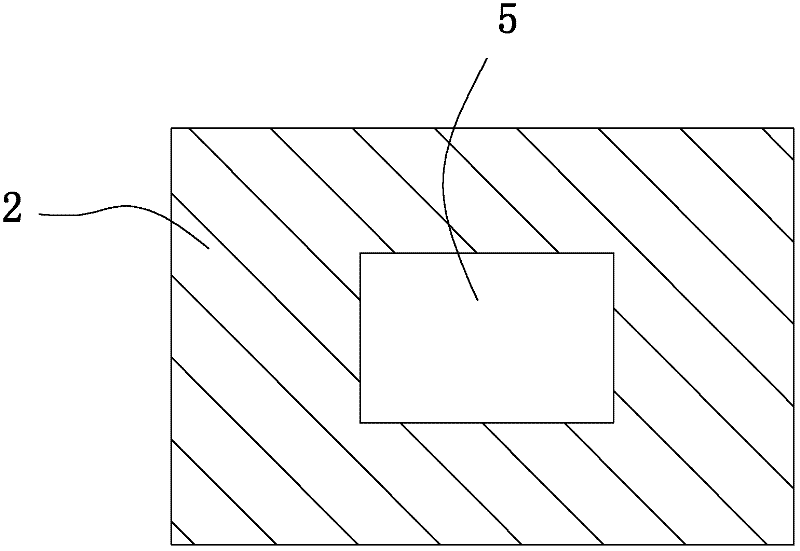

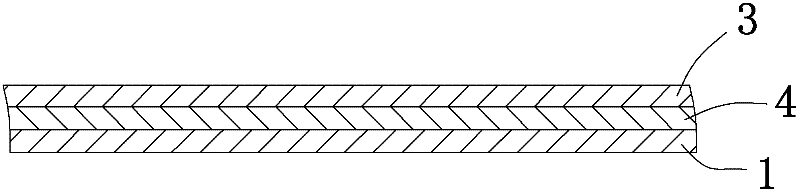

Image

Examples

Embodiment 1

[0076] The internal volume of the baking furnace is 13.5m 3 , the volume of colored glaze on the surface of each glass wine bottle is 30mm 3 , Place 3000 wine bottles at equal intervals in the decal furnace. At this time, the ratio of the sum V1 of the glaze volume on the surface of all glass wine bottles to the inner cavity volume V2 of the decal furnace is: V1:V2=0.007‰. After the glass wine bottle is placed, the temperature of the glass wine bottle is gradually heated to 275°C after 40 minutes, then gradually heated to 580°C after 30 minutes, then kept for 15 minutes, and then gradually cooled down to 565°C after 15 minutes , and then cooled down to room temperature by natural cooling. The surface of the glass wine bottle obtained through this process basically has no black spots. After 8 hours of production in one shift, the burst rate of the wine bottle is 0.01%, and the explosion rate is 1.20%. The remaining unqualified wine bottles include wine bottles. The bottle pat...

Embodiment 2

[0078]The internal volume of the baking furnace is 13.5m 3 , the volume of colored glaze on the surface of each glass wine bottle is 30mm 3 , 4,500 wine bottles are placed at equal intervals in the baking furnace. At this time, the ratio of the sum of the glaze volume V1 on the surface of all glass wine bottles to the inner cavity volume V2 of the baking furnace is: V1:V2=0.01‰. After the glass wine bottle is placed, the temperature of the glass wine bottle is gradually heated to 280°C after 45 minutes, then gradually heated to 585°C after 35 minutes, then kept for 20 minutes, and then gradually cooled down to 575°C after 15 minutes , and then cooled down to room temperature by natural cooling. The surface of the glass wine bottle obtained through this process basically has no black spots. After 8 hours of production in one shift, the burst rate of the wine bottle is 0.01%, and the explosion rate is 1.30%. The remaining unqualified wine bottles include wine bottles. The bott...

Embodiment 3

[0080] The internal volume of the baking furnace is 13.5m 3 , the volume of colored glaze on the surface of each glass wine bottle is 30mm 3 , Place 2000 wine bottles at equal intervals in the baking furnace. At this time, the ratio of the sum of the glaze volume V1 on the surface of all glass wine bottles to the inner cavity volume V2 of the baking furnace is: V1:V2=0.004‰. After the glass wine bottle is placed, the temperature of the glass wine bottle is gradually heated to 285°C after 50 minutes, then gradually heated to 590°C after 45 minutes, then kept for 10 minutes, and then gradually cooled down to 570°C after 15 minutes , and then cooled down to room temperature by natural cooling. The surface of the glass wine bottle obtained through this process basically has no black spots. After 8 hours of production in one shift, the burst rate of the wine bottle is 0.01%, and the explosion rate is 1.10%. The remaining unqualified wine bottles also include wine bottles. The bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com