An organic-inorganic hybrid halide luminescent material and its preparation method and application

A technology of luminescent materials and halides, applied in luminescent materials, organic chemistry, chemical instruments and methods, etc., can solve the problems of poor film-forming charge transport, etc., achieve good stability, simple preparation method, and small quantum yield attenuation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] A method for preparing an organic-inorganic hybrid halide luminescent material of the present invention comprises the following steps:

[0056] S1, take the molar ratio as AX:CuX y ≈0.1~3 precursor drugs, namely quaternary ammonium salt AX and copper halide / cuprous CuX y , dissolved in an organic solvent with a concentration of 0.2-1mM, stirred at room temperature in an inert gas atmosphere for 3-6 hours until the powder is dissolved in the solution, then left to stand for 1-5 hours until the solution is clear, and then filtered the solution with a filter head;

[0057] Put the weighed quaternary ammonium salt AX and copper halide / cuprous in an agate mortar, then place it in an inert gas atmosphere, put the mortar on a heating platform and start grinding, and the grinding heating temperature is 100-140°C. The time is 2 to 4 hours, and the annealing is continued for 1 to 2 hours after sufficient grinding to obtain the desired powder.

[0058] The solvent used for disso...

Embodiment 1

[0067] First, weigh 57.4 mg of cuprous bromide and 168.128 mg of tetraethylammonium bromide and place them in an agate mortar, then put them into a glove box with an inert gas atmosphere for grinding. Grinding on the bench. When heating, the temperature is 100°C, and the precursor drug is ground until the powder particles become smaller and uniform, and the time is 4 hours.

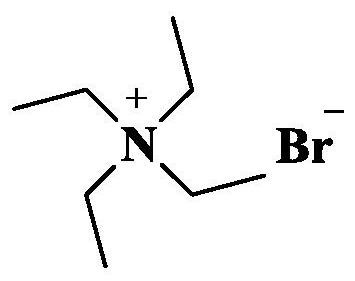

[0068] figure 1 Be that described quaternary ammonium salt is the molecular structural formula of tetraethyl ammonium bromide.

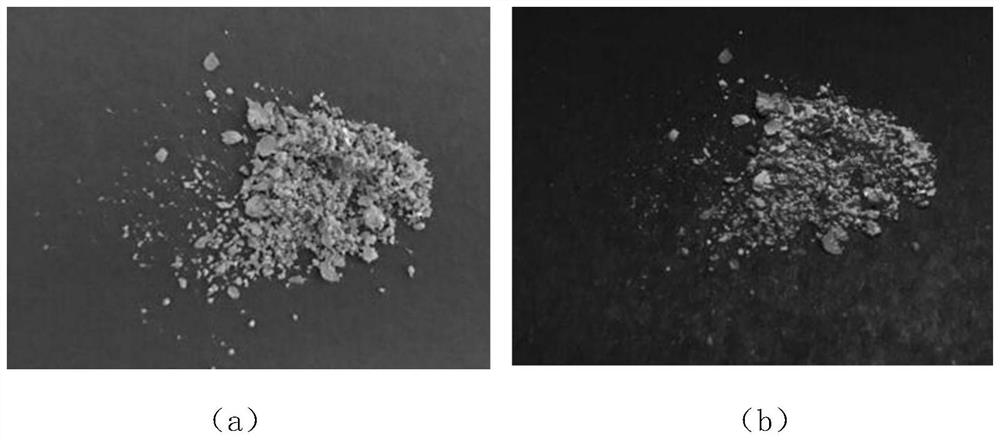

[0069] figure 2 Photographs of the powder prepared by grinding in Example 1 of the present invention under a fluorescent lamp and under an ultraviolet lamp;

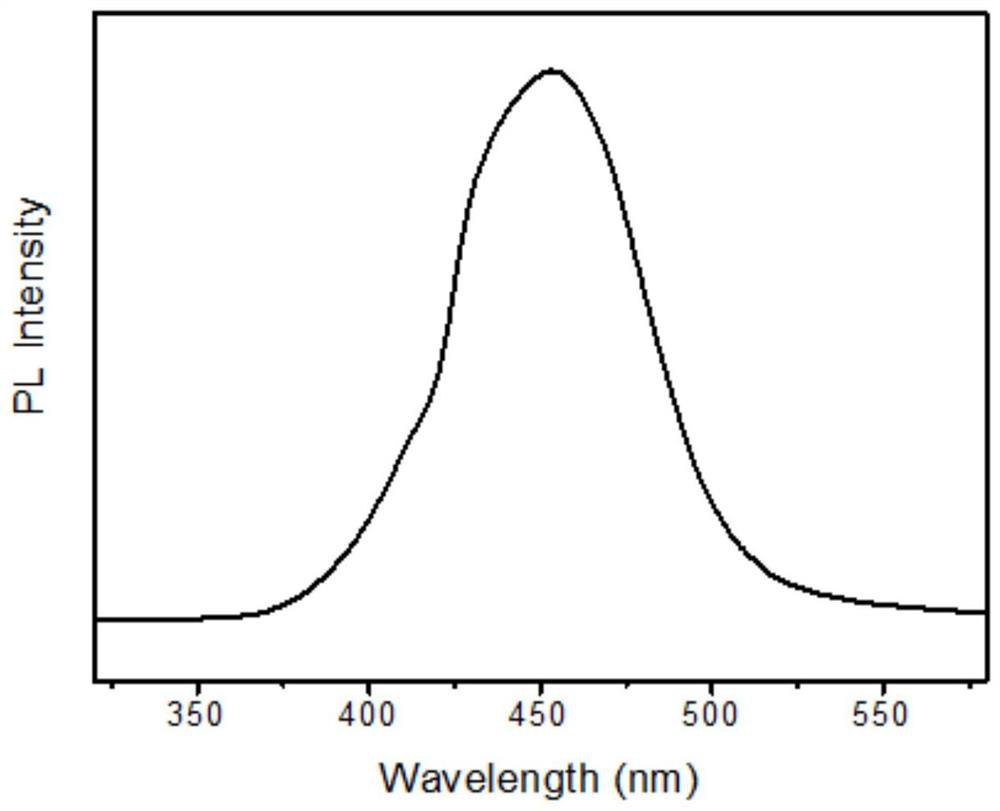

[0070] image 3 It is the PL emission peak of the powder prepared by grinding in Example 1 of the present invention;

[0071] Figure 4 It is the CIE diagram of the powder prepared by grinding in Example 1 of the present invention;

Embodiment 2

[0073] First, weigh 76.2 mg of cuprous iodide and 168.128 mg of tetraethylammonium bromide and place them in a serum bottle, then add 1 ml of dimethyl sulfoxide as a solution, add polytetrafluoroethylene magnets in a nitrogen-filled The glove box was thoroughly stirred. After stirring for 3 hours, the solution was left to stand for 1 hour until the solution became clear. Aspirate 200 microliters of the precursor solution with a pipette gun, and drop it on the cleaned substrate (for example, glass slide / quartz slide / ITO glass slide). At a rotational speed of 1000 rpm for 80 seconds, the spin-coated substrate was moved to an annealing table, and annealed at a temperature of 80° C. for 80 minutes to obtain a halide film.

[0074] Figure 5 For the PL spectrum and absorption spectrum of the prepared film, it can be seen that the prepared halide has an emission peak with a half-maximum width of 80nm at 462nm, and its absorption peak position is at 280nm. It can be seen from the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com