Method for preparing acrylate water-based dispersion by continuously dripping under low temperature condition

A water-based dispersion and acrylate technology, applied in applications, coatings, inks, etc., can solve problems such as long holding time, high reaction temperature, and low neutralization degree of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The acrylate aqueous dispersion obtained by the preparation method of the acrylate aqueous dispersion of the present invention has the following advantages:

[0045] 1. The product has good storage stability. Through the appropriate formula and process conditions described above, the obtained product has very good storage stability, and the performance does not change after being placed at room temperature for more than one year.

[0046] 2. The production stability is good. The acrylate water-based dispersion is prepared by continuous dropwise addition at low temperature, which makes the product production reproducible and will not cause changes in product performance due to excessive temperature or too much one-time feeding.

[0047] 3. The product is green and environmentally friendly. The organic solvent content in the product obtained by the adopted formula design is less than 8%, which meets the requirements of the international green and environmental protection w...

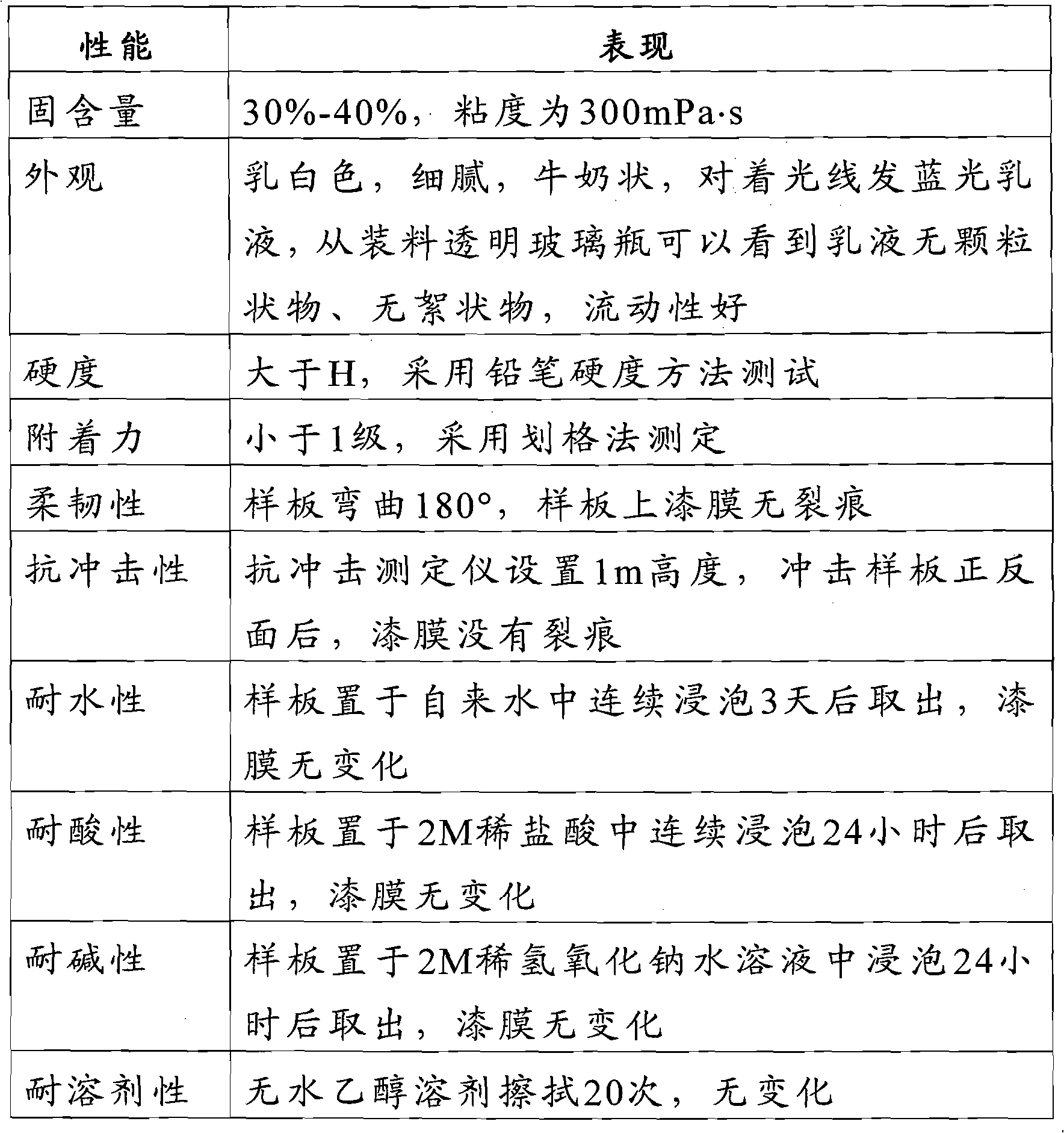

Embodiment 1

[0065] 500g of ethanol, 5g of n-dodecyl mercaptan and 30g of ethylene glycol butyl ether were placed in the reactor for mixing and stirring, and the temperature was controlled at 80°C.

[0066] Add 200 grams of methyl methacrylate, 100 grams of butyl acrylate, 50 grams of hydroxypropyl methacrylate, 10 grams of acrylic acid and 5 grams of azobisisobutyronitrile dropwise at a constant speed, and the reaction time is 1 hour. The internal temperature is controlled at 80° C., and the mixture of pentyl acrylate, propyl methacrylate and azobisisobutyronitrile is added dropwise within the reaction time. Keep warm for 2 hours, the temperature is controlled at 80°C, add 1g of azobisisobutyronitrile and 1g of n-dodecyl mercaptan during the heat preservation, so that the unreacted monomers can be completely reacted, and at the same time, some molecules with too high molecular weight can be reduced. molecular weight.

[0067] Add the mixture of pentyl acrylate, propyl methacrylate and az...

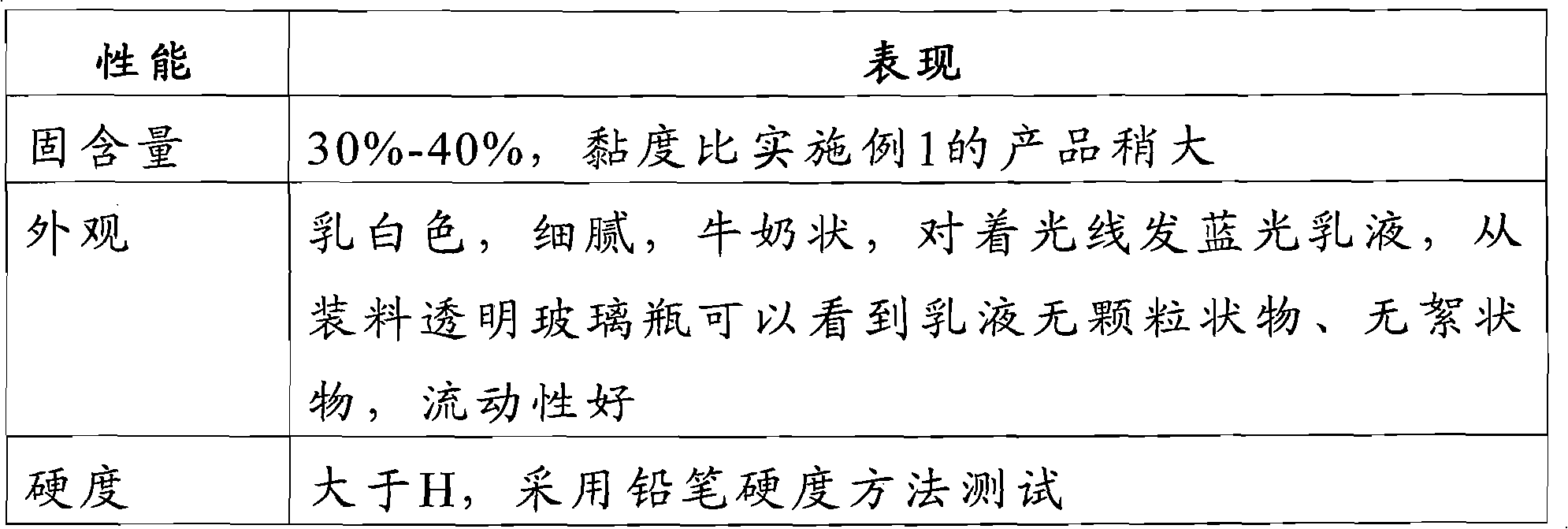

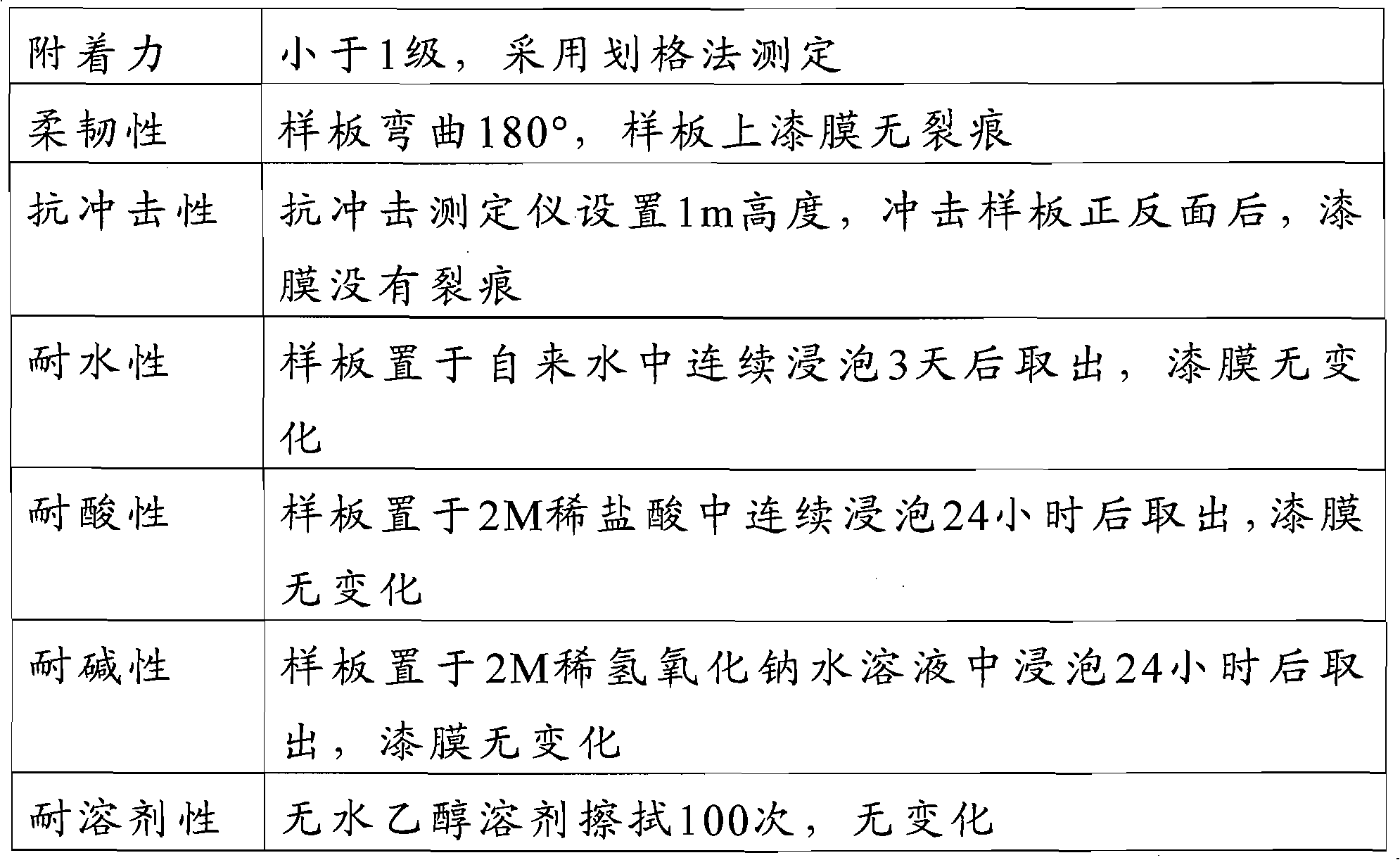

Embodiment 2

[0076] Put 500g of acetone, 6g of n-dodecyl mercaptan and 40g of ethylene glycol butyl ether into the reactor, mix and stir, and control the temperature at 50°C.

[0077] The mixture of 200 grams of hexyl methacrylate, 100 grams of butyl acrylate, 50 grams of hydroxyethyl methacrylate, 10 grams of methacrylic acid and 5 grams of azobisisobutyronitrile was added dropwise at a uniform speed, and the reaction time was 3 hours. During the reaction time, the temperature was controlled at 50° C., and the mixture of ethyl methacrylate, ethyl acrylate and azobisisobutyronitrile was added dropwise during the reaction time. Keep warm for 2 hours, the temperature is controlled at 50°C, add 2g of azobisisobutyronitrile and 2g of n-dodecyl mercaptan during the heat preservation, so that the unreacted monomers can be completely reacted, and at the same time, some molecules with too high molecular weight can be reduced. molecular weight.

[0078] Add the mixture of ethyl methacrylate, ethyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com