High-energy mixer for well cementation in oil and gas fields

A technology for oil and gas fields and mixers, which is used in wellbore/well components, earthmoving, sealing/packaging, etc. Pulp effect, improve wear resistance, reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

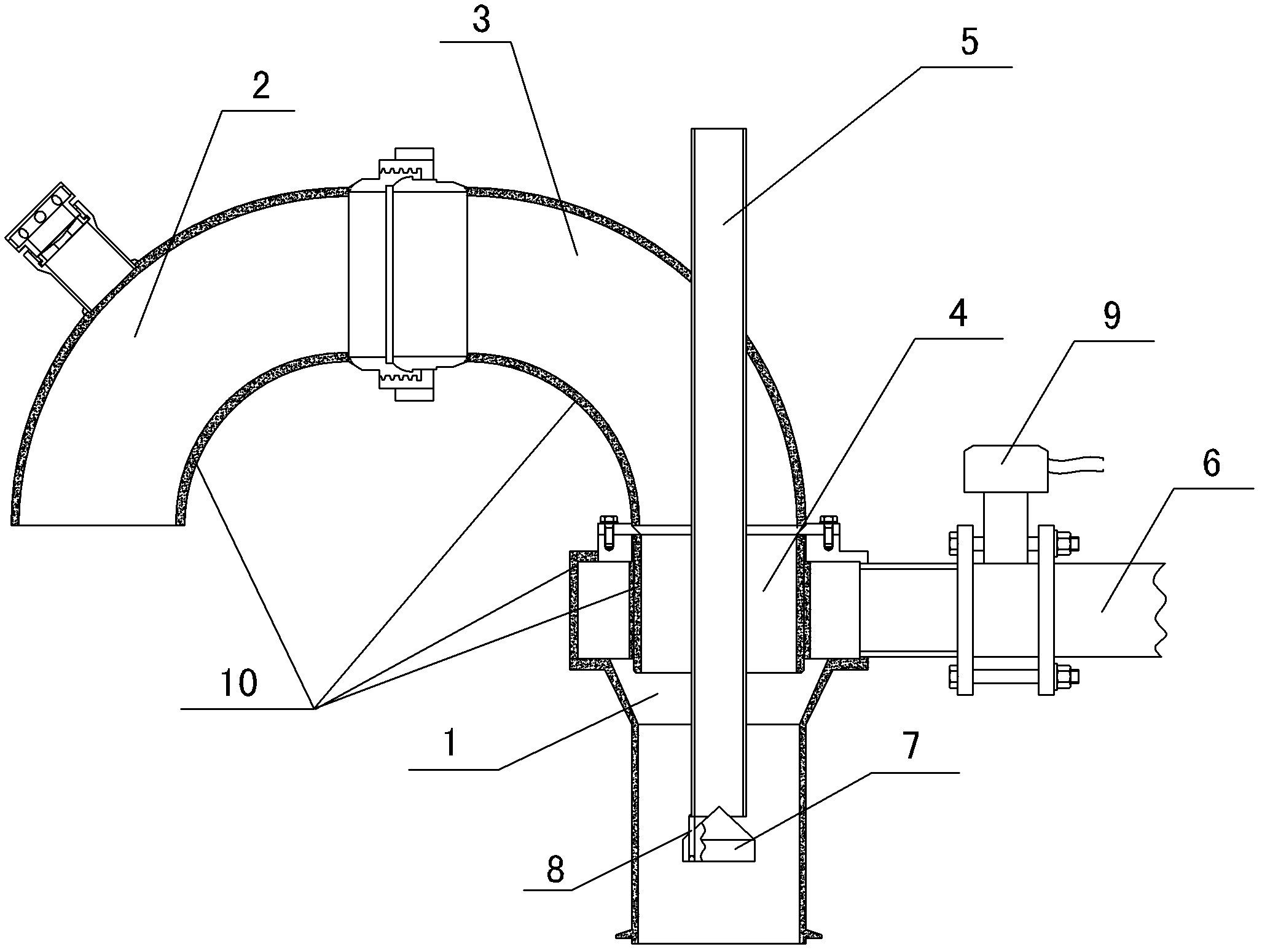

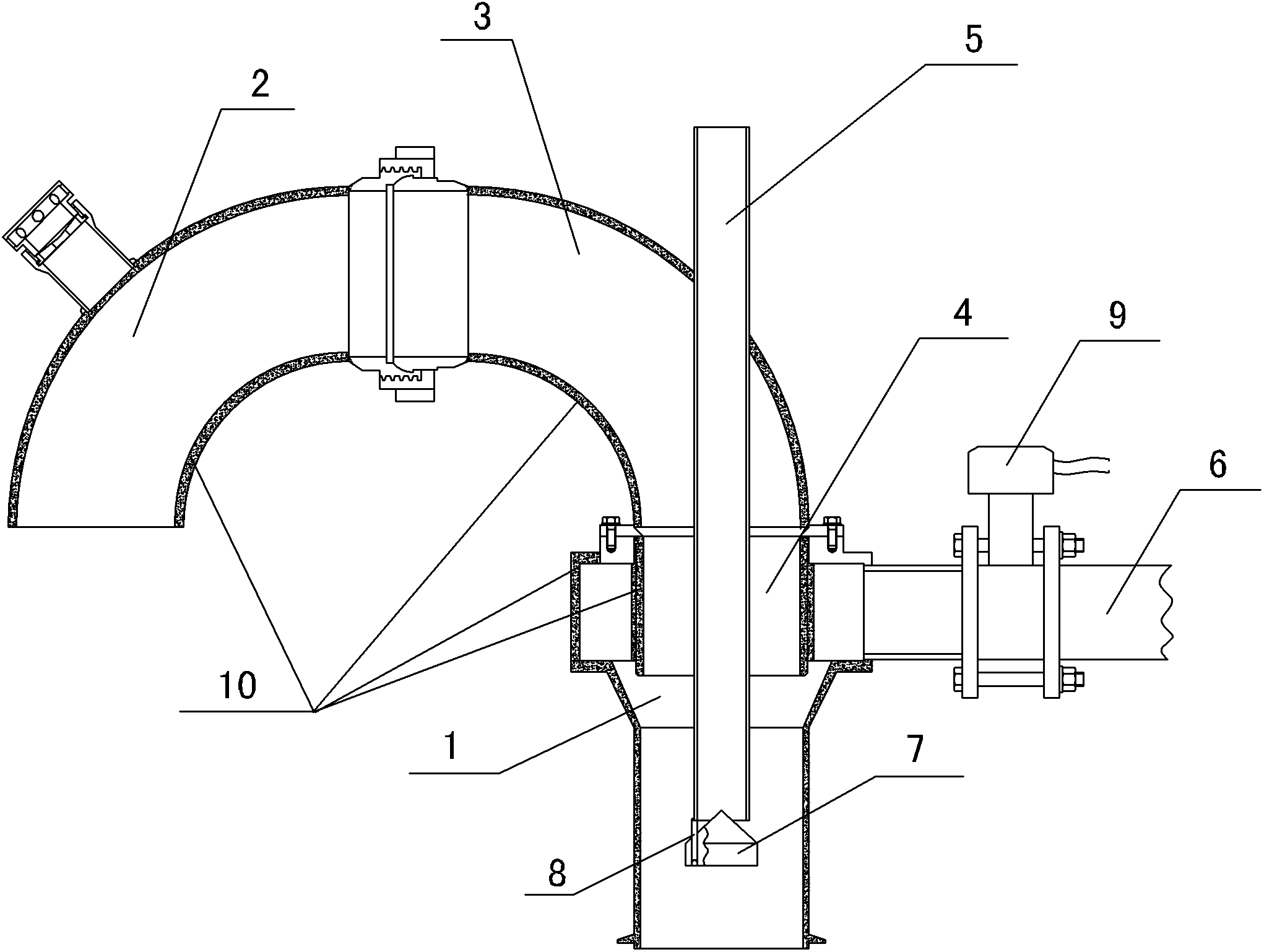

[0026] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

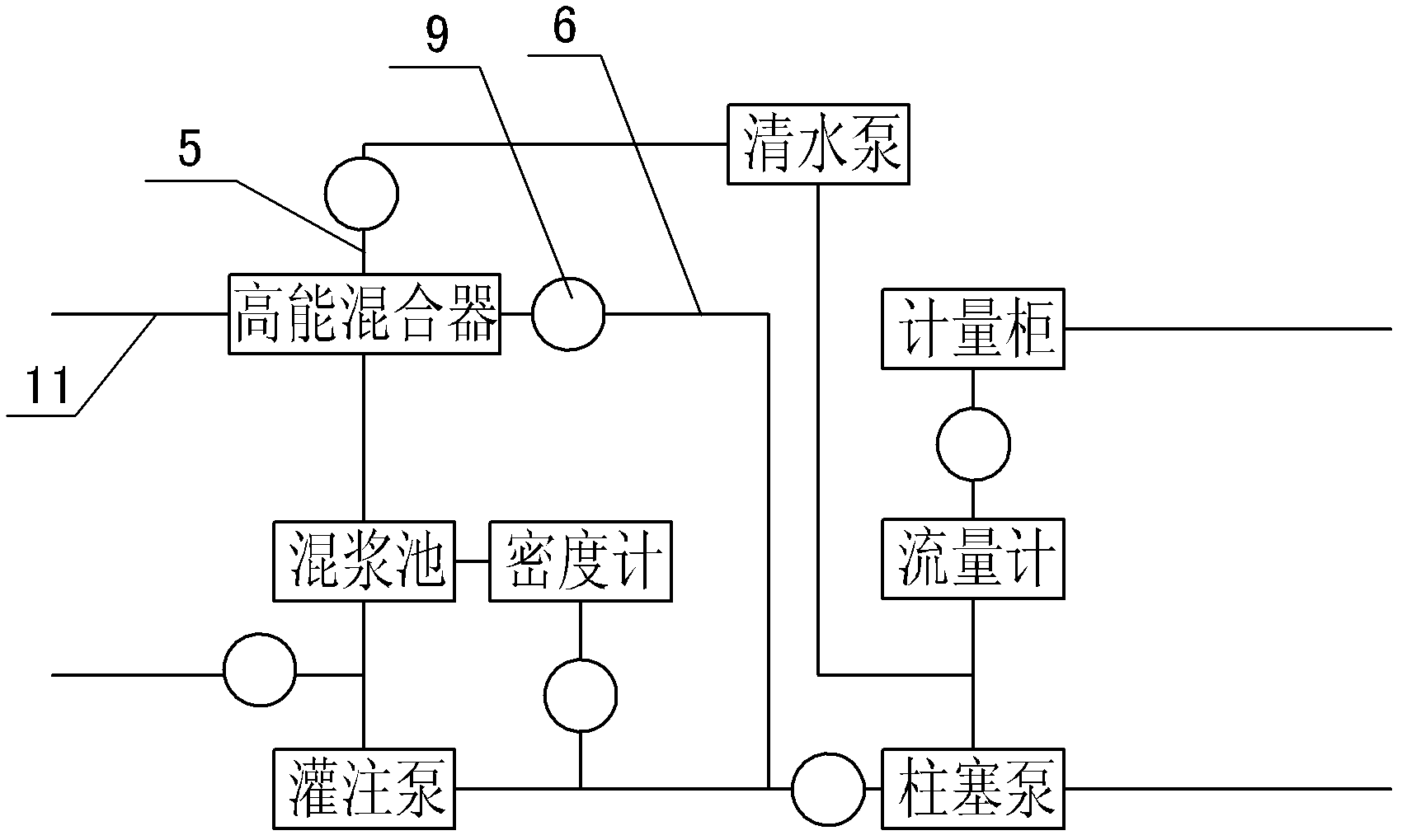

[0027] like Figure 1~2 As shown, the ash supply pipe 11 includes an upper ash elbow 2, an injection elbow 3 and a bushing 4, the bushing 4 is located inside the shell 1, the bottom end of the shell 1 is connected to the mud mixing tank, and the upper water pipe 5 is along the jet elbow. 3 The central direction of the outlet is welded together with the spray elbow 3, the water outlet end of the upper water pipe 5 is located at the lower part of the shell 1, the secondary ash mixing pipe 6 is connected to one side of the shell 1, and there is a branch below the water outlet end of the upper water pipe 5. The water thimble 7 and the water diversion thimble 7 are fixedly connected to the pipe wall of the upper water pipe 5 through the support pin 8. The secondary ash mixing pipe 6 is a single pipeline structure, and the secondary ash mixing pipe 6 is welded on the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com