Hydraulic oil piston type natural gas sub-station compressor

An oil piston and natural gas technology, applied in the field of hydraulic oil piston natural gas substation compressors, can solve the problems of reduced energy consumption, high investment in station construction, high energy consumption, etc., and achieves slow temperature rise, power saving, steady and smooth travel speed uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

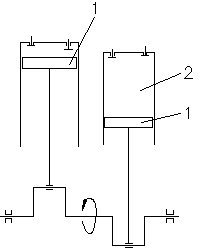

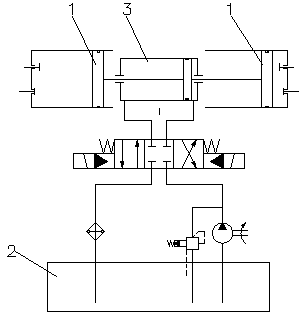

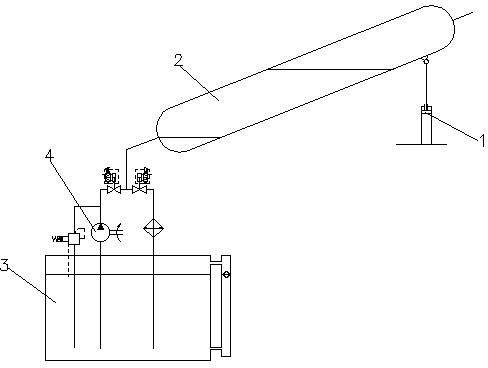

[0043] please see Figure 4 , Figure 5 , this embodiment describes a hydraulic oil piston natural gas substation compressor, which consists of a high pressure oil pump 1, a pressure control valve 2, a pressure oil tank 3, a liquid reversing valve 4, a flow sensor 5, a bridge valve group 6, a gas Compression cylinder right tank 7, gas compression cylinder left tank 8, pressure sensor 9, pressure relay 10, high pressure gas storage cylinder 11, automatic control system 12, oil replenishment system 13, inlet valve 14, outlet valve 15, check valve 16 and pressure gauge. Wherein, an inlet valve 14 is installed beside the inlet of the inlet pipeline, and an outlet valve 15 is installed beside the outlet of the outlet pipeline. A pressure sensor 9 is arranged behind the inlet valve 14, and the inlet pipeline behind the pressure sensor 9 is respectively connected to the pressure oil tank 3 and the bridge valve group 6 through a three-way pipe, and the bridge valve group 6 is compos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com