Water pump impeller made of polyphenylene sulfide (PPS) material and manufacturing method of water pump impeller

A technology of water pump impeller and polyphenylene sulfide, which is applied to components, pumps, and pump components of pumping devices for elastic fluids, and can solve problems such as high power consumption, reduced water pump efficiency, and poor dynamic balance of impellers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

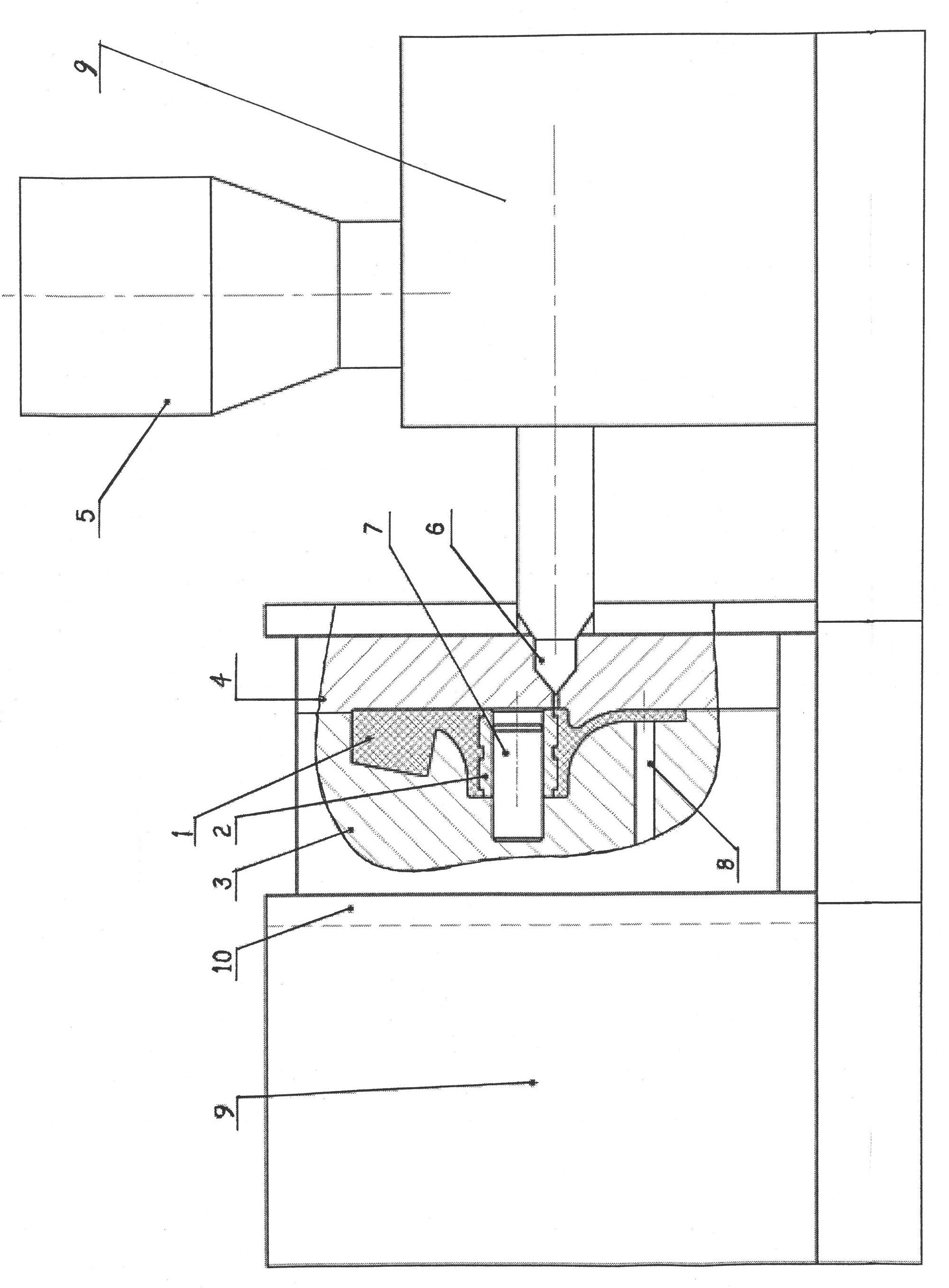

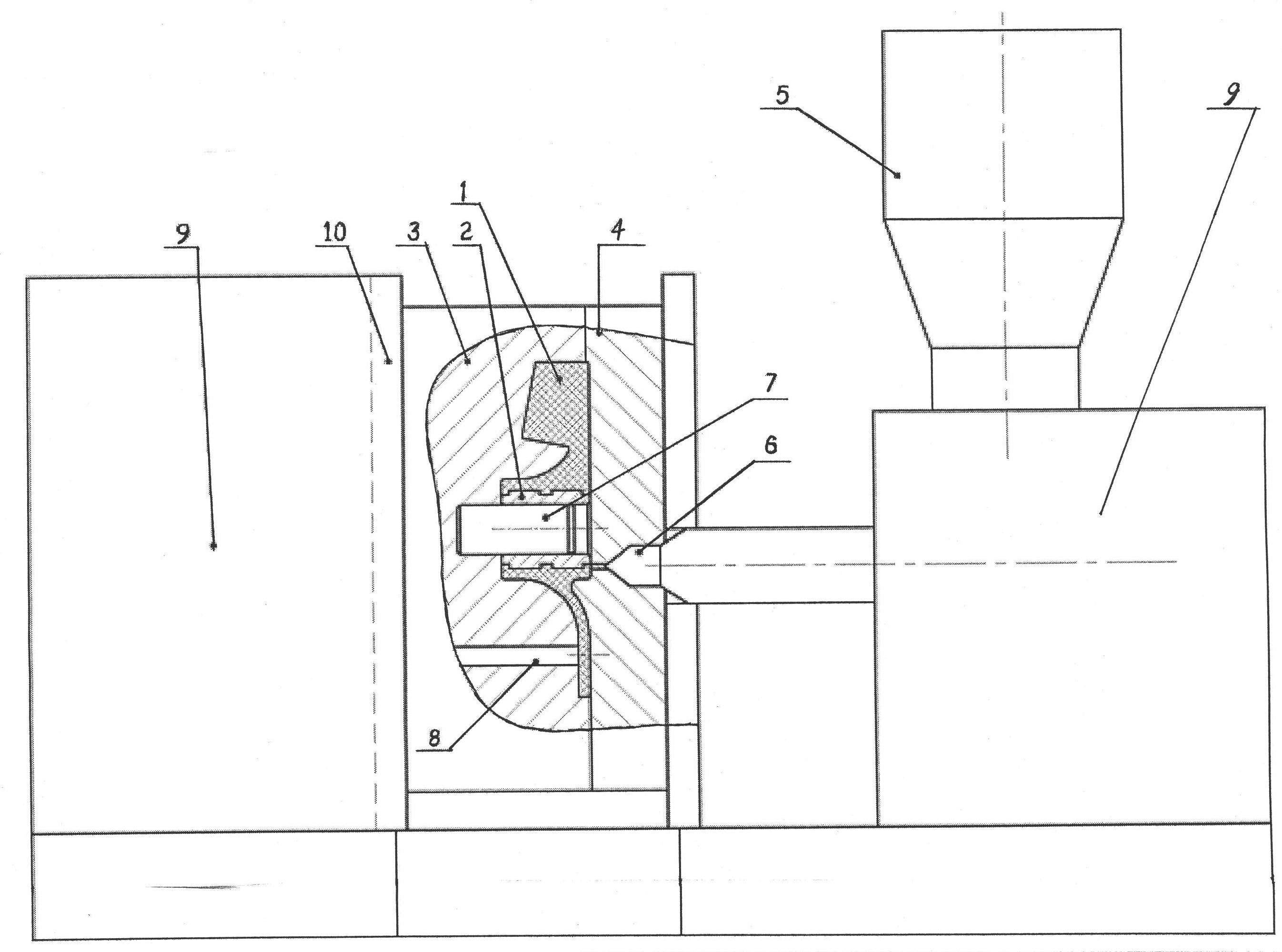

[0009] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

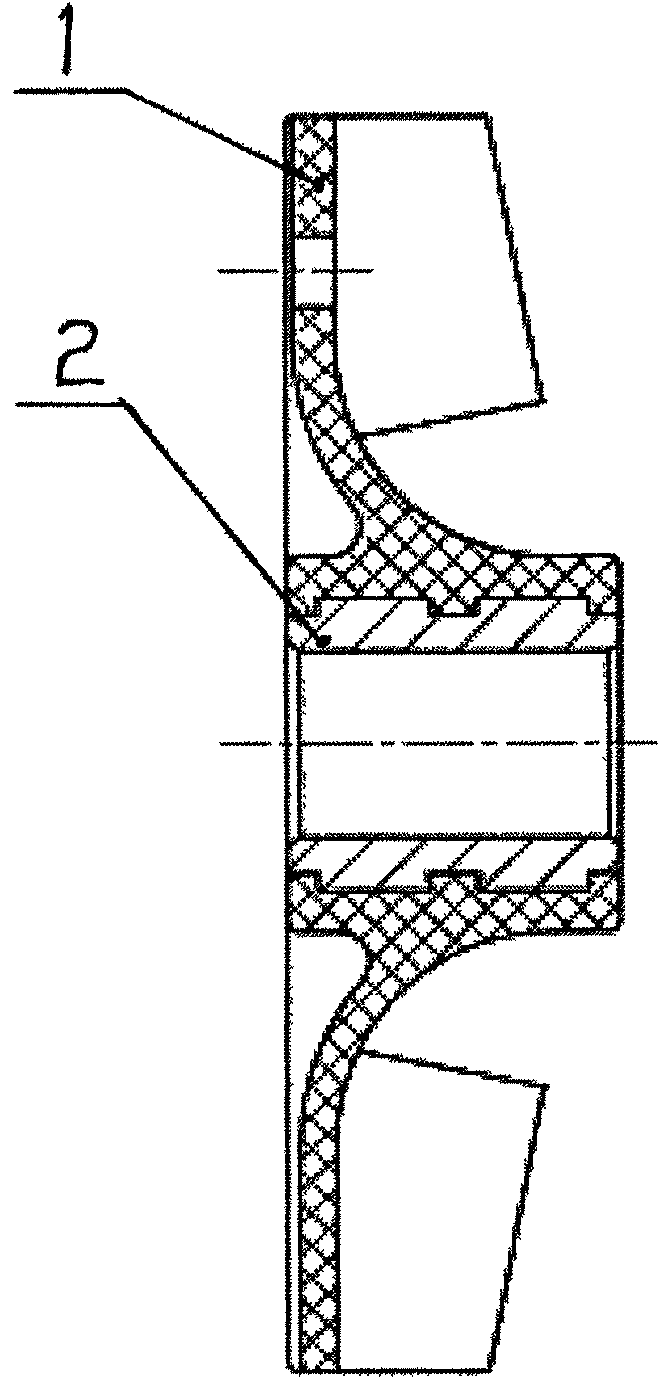

[0010] refer to figure 1 It can be seen that the water pump impeller made of polyphenylene sulfide material of the present invention includes the impeller body 1, and the material of the impeller body 1 is pure polyphenylene sulfide (abbreviated as PPS) accounting for 50-70% of the weight of the impeller body and accounting for 50-70% of the weight of the impeller body. 30-50% of the weight is made of modified glass fiber engineering plastics, and the impeller body 1 is equipped with an impeller seat 2 with an inner groove, and the impeller seat 2 and the impeller body 1 are integrally formed.

[0011] The water pump impeller made of PPS material includes an impeller body 1 and an impeller seat 2 made of PPS material. The forming process of the water pump impeller is mainly composed of injection molding machine 9 (including injection molding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com