Method for preparing rust layer sample for being observed by scanning electron microscope

A technology of scanning electron microscope and rust layer system, which is applied in the field of metallographic samples for scanning electron microscope observation, can solve problems such as floating, affecting the accuracy of measurement, and charge accumulation, so as to achieve the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0023] The rust sample preparation method for SEM observation of the present invention may further comprise the steps:

[0024] a. Sampling: Cut the sample with rust layer into two small samples of 15mm×15mm with a precision cutting machine at low speed;

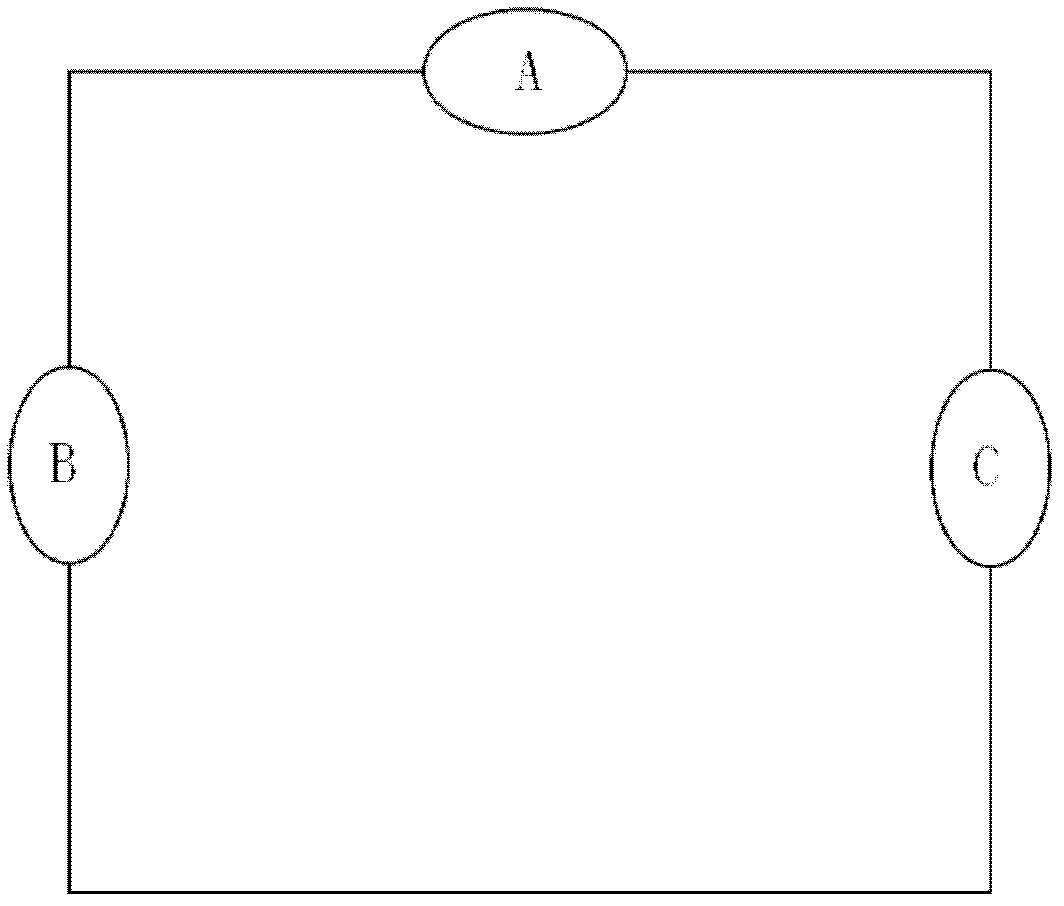

[0025] b. Spot welding: stack two small samples, and perform spot welding between three sides of the two small samples, such as figure 1 Spot welding positions A, B, C shown;

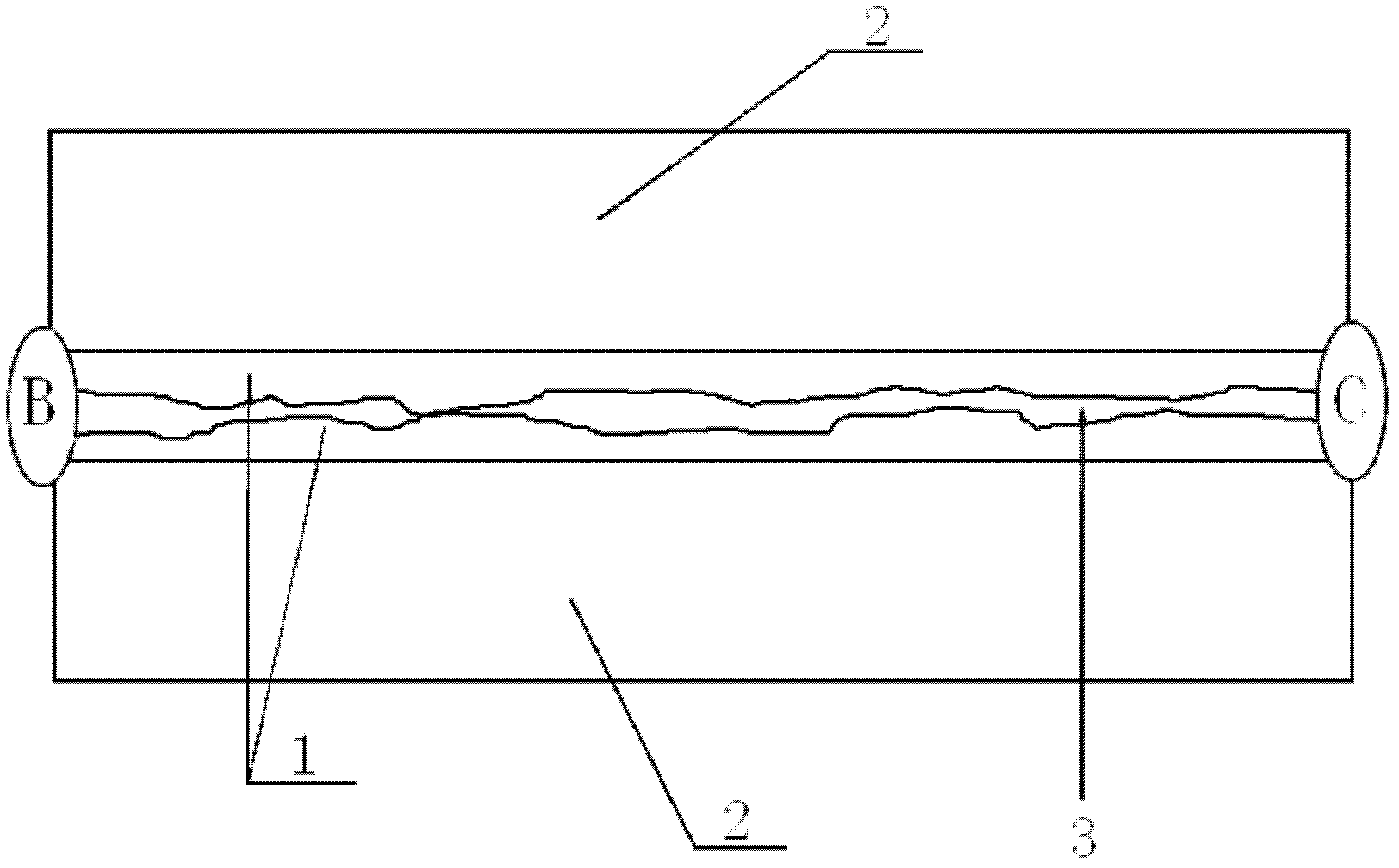

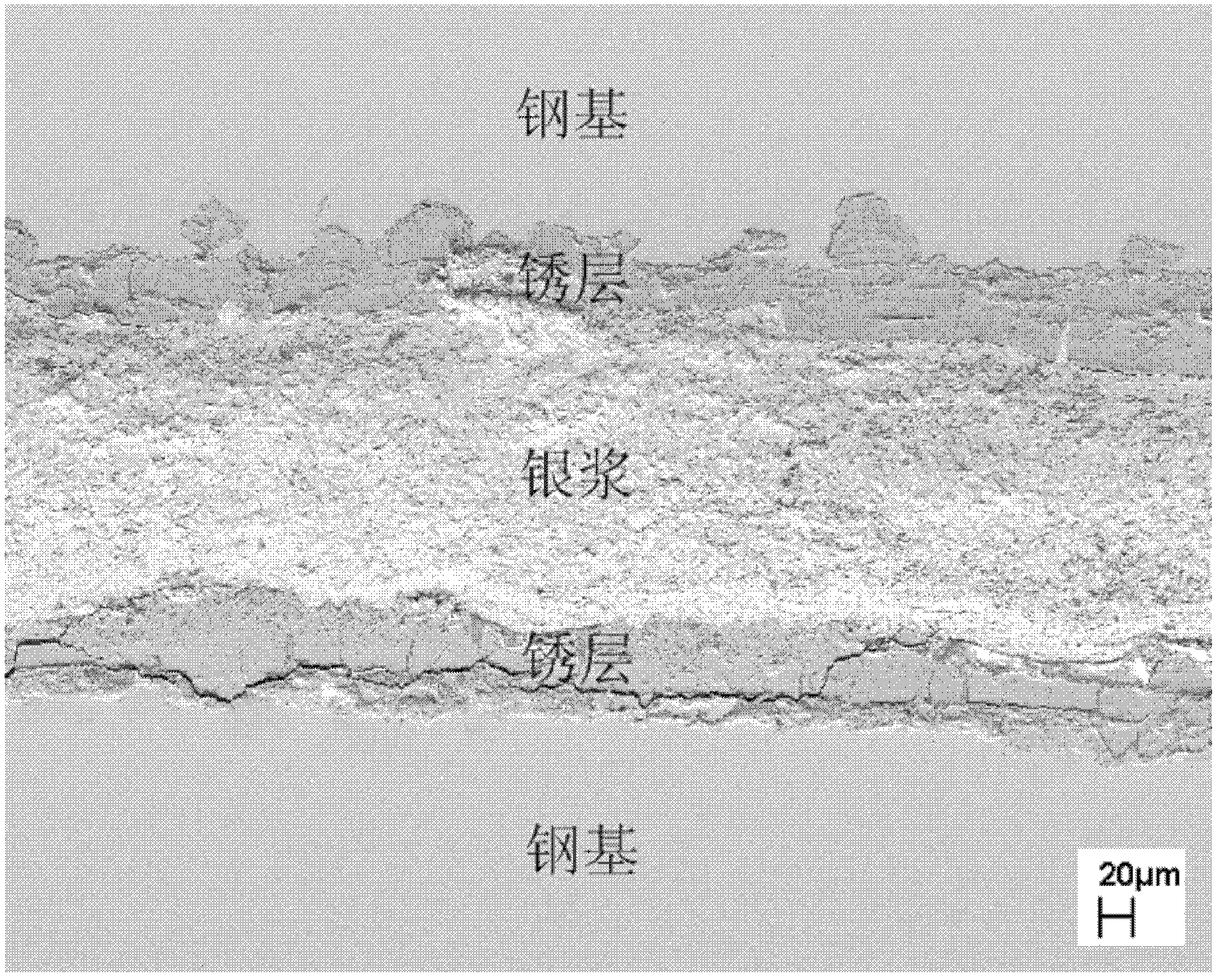

[0026] c. Grouting: pour conductive silver paste into the middle of two small samples, so that the conductive silver paste is filled between the two small samples, such as figure 2 Shown is a schematic diagram of the cross-sectional structure after pouring the conductive silver paste. The surface of the two small samples is a rust layer 1, and the inside is a steel base 2. The conductive silver paste 3 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com