Method for detecting 18 varieties of protein hydrolytic amino acids in milk powder through high-performance liquid chromatographic method

A high-performance liquid chromatography and proteolysis technology, which is applied in the field of high-performance liquid chromatography detection of 18 kinds of proteolytic amino acids in milk powder, can solve the problems of poor universality and high cost, and achieve the effect of strong universality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

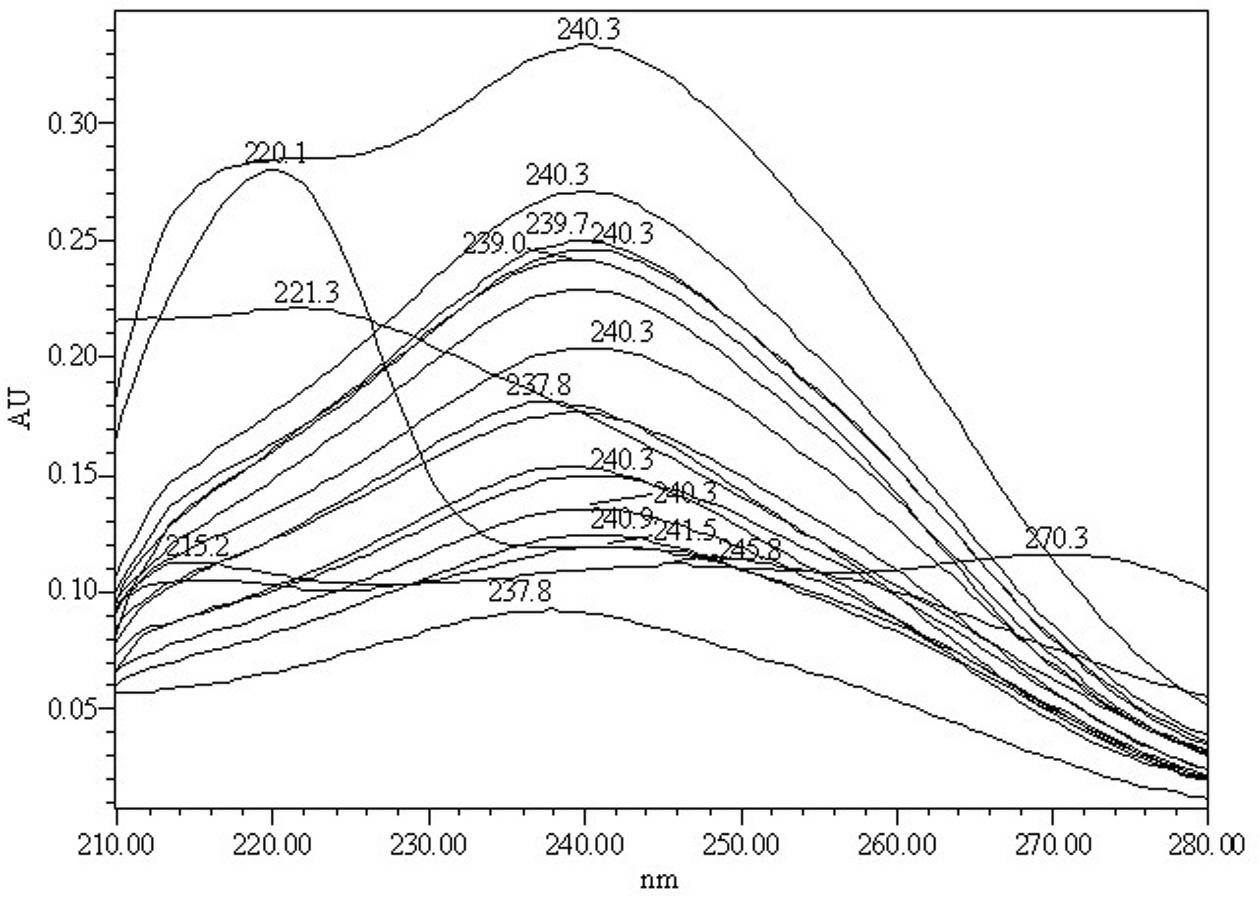

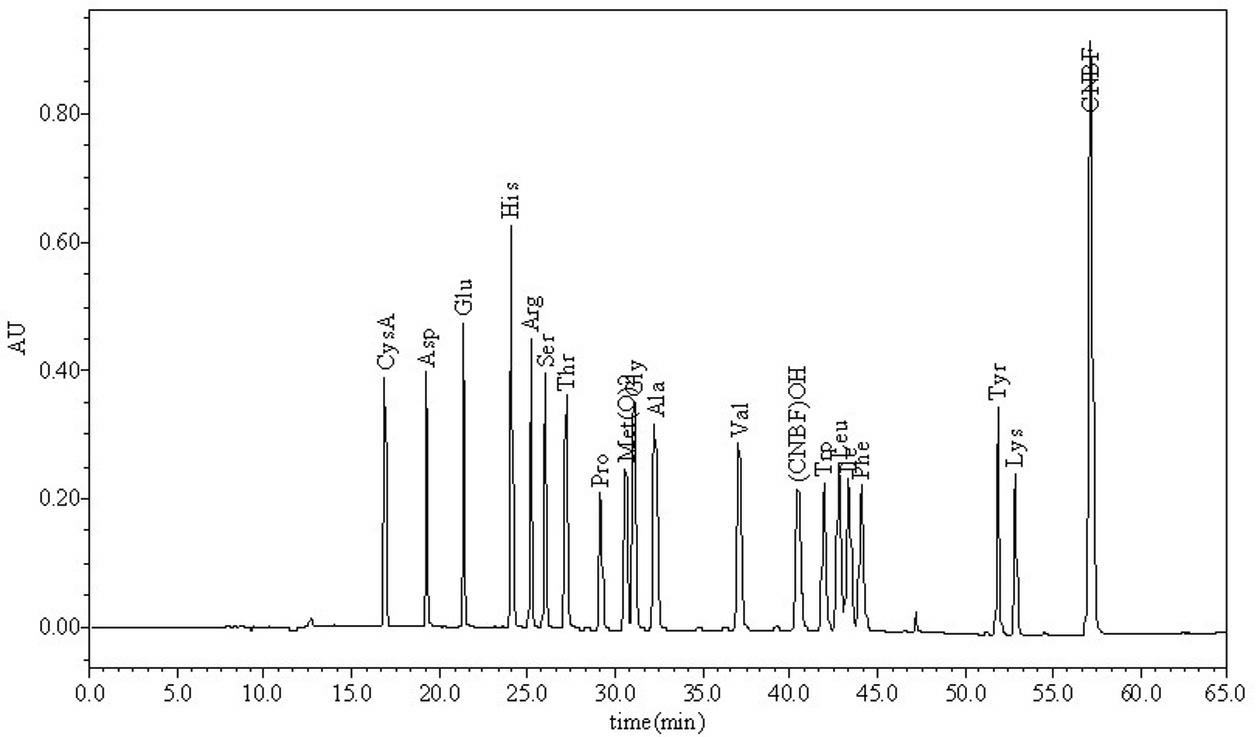

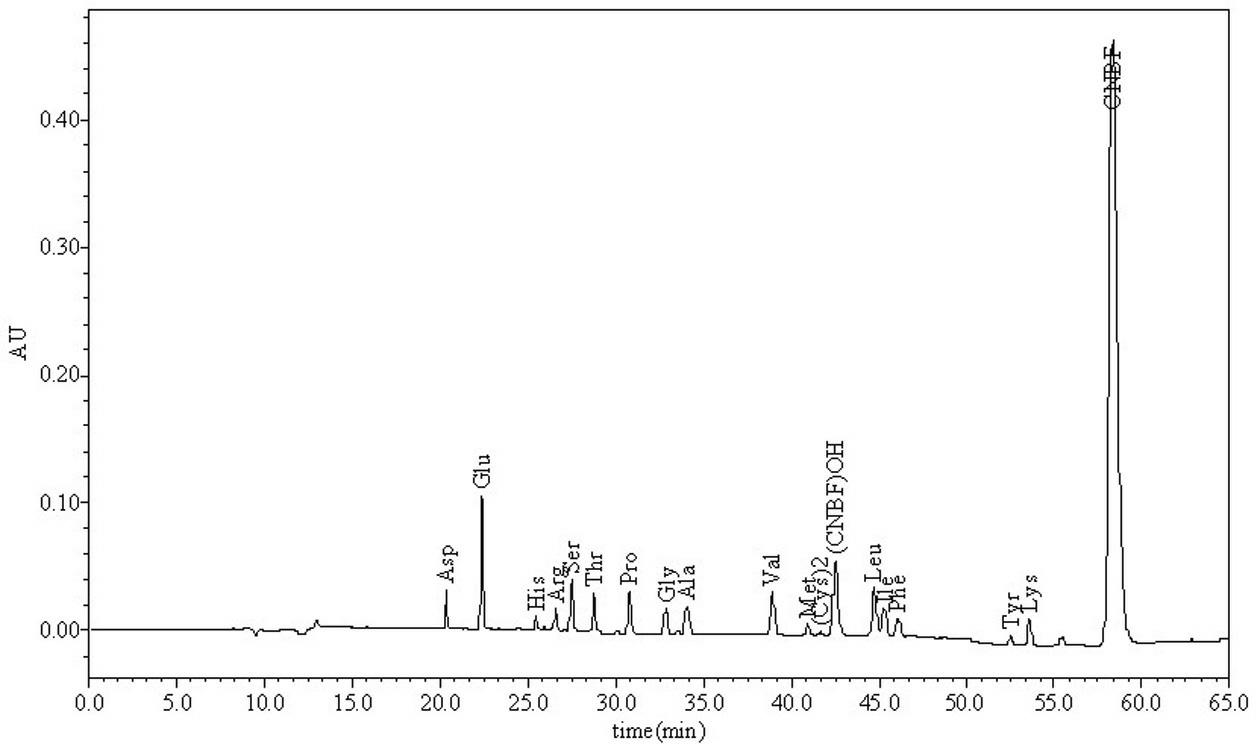

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in combination with the accompanying drawings and specific embodiments.

[0033] The high-performance liquid chromatography detection method of 18 kinds of proteolytic amino acids in milk powder comprises the following steps:

[0034] (1) Preparation of milk powder hydrolysis samples:

[0035] Three different pretreatment methods, i.e. conventional hydrolysis, oxidative hydrolysis, and alkali hydrolysis, were used to hydrolyze the milk powder to obtain milk powder hydrolyzed samples respectively; the milk powder was selected as infant growth milk powder, and the following scheme could be adopted for specific implementation:

[0036]① Conventional hydrolysis method: Weigh 0.0500g (accurate to 0.0001g) of milk powder and transfer it to an ampoule or hydrolysis tube, add 10ml of 6mol / L hydrochloric acid, add 2-3 drops of dissolved fresh phenol, and fill it with high-purity nitrogen for 15 minutes , Seal the ampoule bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com